-

Posts

150 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Owen Hinsman

-

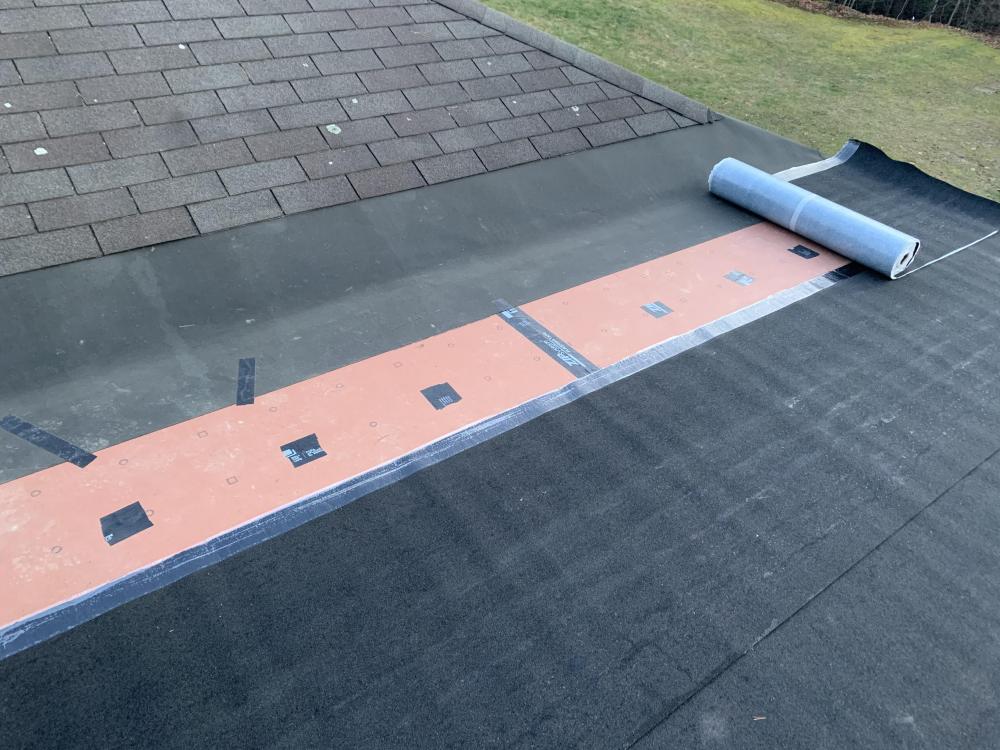

That’s exactly what we did Frosty. There’s 5/8 ZIP board screwed down covered at every opening with ZIP tape. Then proper flashing and drip edge and then Grace with asphalt (not shingles) on top.

-

I've seen one of those on Kayne & Sons Blacksmith's Depot going for around 1k. But that wouldn't be the one you have, this one's new.

-

What did you do in the shop today?

Owen Hinsman replied to Mark Ling's topic in Blacksmithing, General Discussion

Got down to 15 or so overnight in ME... and then woke up to 1/2 inch of ice on everything. Nice Ouroboros pendant Rojo! -

I've been blacksmithing for a few years now, but only recently have I started building my shop. I already have some tools and an anvil, but so far I have been put off from buying a gas forge online because most of them aren't right for what I'm trying to do. (which is mostly knives, axes, and a whole lot of hooks and other ornamental ironwork.) However, I have no idea where to start with building a forge, so I figured I'd ask some more experienced smiths about it. I'm not totally against buying a forge, but building one seems like the better option for me.

-

snow load isn't a problem due to the rough cut 2x10 rafters, which should hold the snow we get each year just fine. I'll talk to my dad about just using rubber, but he wants to do shingles. The pitch definitely isn't changing now!

-

Good news and bad news. Good news, the rafters and zip boards are all up. The bad news is the hack who built the garage did nothing properly, from stapling on the overhanging drip edge the not having rafters and studs (none of them) 16” on center, which means that we had to space the rafters all funny.

-

It’s almost flat with 2x10 rafters and sealed plywood. Possibly asphalt shingles, maybe a tin roof

-

-

Big bolts and brackets. They’re set with the top of the beam right below the bottom of the wall sill and sitting on top of 2x6s.

-

-

All three beams are now up, but it's dark now so I'll post a picture tomorrow morning. By the way, does anyone know how to put a picture into my profile picture? I can't seem to figure it out.

-

IMG_1254.MOV

-

We actually had to use PVC rollers to move the beams. Plus about ten minutes ago the first beam went up! I'll put a video of the process up, but the computer doesn't like me at the moment...

-

Yeah they are. The frame actually bent when we tried to lift it into place.

-

Well, the wood arrived on Friday, so we’ve spent the last few days figuring out how to get it up. The posts are 6x6, the beams 4x12, and the rafters are 2x10s. As the beams weigh about 600# it’s a little difficult. There is also an electric winch rated for 3500# in play.

-

Look up Chevron twist. That should be what you're looking for.

-

What have you been given?

Owen Hinsman replied to Ridgewayforge's topic in Blacksmithing, General Discussion

after hearing that I was a smith at a neighborhood bonfire, my new neighbor gave me a dozen (real) used horseshoes. -

I don’t thinks so.... but it won’t be long!

-

yeah he’s great. That’s Otter, my chocolate lab.

-

Both of the holes are now dug and naturally, being in Maine, there are tons of rocks. But the concrete is in and the bolts are set.

-

We’re finally starting construction of my workshop, so I figured I’d start a thread about it. So here’s the half ton of concrete and the tubes for it in my garage.

-

What did you do in the shop today?

Owen Hinsman replied to Mark Ling's topic in Blacksmithing, General Discussion

I managed to get out into the shop today, so I dressed my new hammer and tried my hand at a basket twist. -

I was thinking about forging (at least partially) a Hnefatafl set, and I think that chess and the like would be fun to make as well. Have any of you ever forged board games? I haven't seen any threads on it yet, so I figured I'd ask.

-

Why not use a small propeller under the water in a wire cage? It would keep the water moving so it doesn't freeze. Or maybe just one of those chemistry stir stick thingys would work.

-

It was definitely the best anything for sale. Did I see you at the meet? I was the guy in a leather apron down at the open forge area.