mpc

Members-

Posts

74 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by mpc

-

I’ve see this as it applies to grinders. I met someone at a family thing who has been making better knives than I could hope to make for years with a 1 x 30 from HF.

-

Did they come with the heater packs? Those are fun.

-

I’m pretty nervous about disagreeing with Frosty on this site but this statement is contrary to conventional wisdom. The idea of rotating stock is to buy more of the stuff you do use so that nothing gets old enough to go bad. If you typically go through 2-3 of something in a month, buy 8-12. Then, at the end of the next month, buy 2-3 more and put the new stock at the back of the shelf. That way your stock on hand should never be more than a few months old. The other reason for buying the stuff you actually eat is to avoid waste. You’re less likely to screw up or make too much or too little of something that you already know how to make. If you want something you can stick in a “bug out bag” and leave for 20 - 30 years, look at things like the Mountain House backpacking meals. They’re supposed to be good for 30 years.

-

I am getting one of the little HF flux core welders as a gift from a friend. He got a better welder and has the HF “just sitting around.” It is one of the inverter welders that says it will put our up to 125 Amps (think it is the smallest one they make). Is it safe to assume that this will be enough for small projects using 3/16 angle iron, tacking billets, and attaching rebar to billets?

-

I got the idea from watching a woman use a tortilla press.

-

I am not being sarcastic when I say I appreciate the concern for safety expressed by Frosty & Mikey98118. I think that mentioning these things might actually save lives. In my case, I figured running it with the propane under the forge was a bad idea but now you have me worried about how I’m storing propane cans. Why can’t I store a propane can on the cart when I’m not using it? My usual practice is to shut down the forge, disconnect the hoses, let everything cool down, and then put it away in the garage (which is immediately under my daughters’ bedroom). The propane cans aren’t on a cart with the forge now but they’re next to it. Am I doing it wrong?

-

That’s one of the questions I had. How much force is actually necessary to move the metal enough to draw out a billet? If you had a “metal smasher” with a business end that’s about 1/2” x 3,” I wonder what it would take to generate 25 tons. I’m aware this may be a stupid question. There’s an old joke that applies to me about law school being the home for people with no capacity for mechanical or mathematical thinking.

-

This might be a stupid idea but has anybody ever tried making a forging press using a really big lever? I’m not great at math or engineering but I wonder how much force could be generated by a device like the one pictured. If you maximize the length of the lever and all the little angles and, if the lever was sufficiently strong, I’m guessing you could get it done. For those of us who can’t afford a hydraulic press it might offer the opportunity to get a pretty good number of presses per heat.

-

Not really a “forge” question but it’s forge related: I want to put my forge on a rolling cart. I’ll probably just grab a “Steel Service Cart” from HF. That way I can put my propane tank on the bottom shelf and just wheel the whole thing out as a unit. Here’s my question... Do I need to put something extra on the top shelf to protect or insulate it? I keep thinking I need to put something under the forge across the top of the cart. I have this vision of hot or molten things falling out of the forge, dripping down to my propane tank, and causing an explosion that somehow destroys the entire Northwestern US. But, my own mental issues aside... Is it a good idea to put something on there? Maybe just to make it a little more sturdy? I was thinking maybe some cheap fire brick but, even the crappy 1/2 cut stuff would cost about $80. I don’t think plywood is a good idea. I was thinking maybe some cement backer board? Does anybody have any suggestions?

-

I’ve been looking for months. I was actually giving up on finding something local and was coming to terms with having to pay to ship. But, before I started making offers on stuff out of state I thought I’d call these guys one more time. I had been watching this for about 5 months but they were just asking WAY too much ($300). I had offered them $100 a few months ago and they said no. I called and asked if they were ready to come down and they said yes.

-

I will. I just got it home. The prior owner had it welded to a piece of RR track that he sunk into the ground. I had to cut that away and then I’ll start cleaning it up.

-

-

I was searching for another thread when I happened upon this one. I thought I’d share something in case anybody is still following. Larry was a friend of a friend. I never met him but after he passed I heard about his life and work from my friend. I also heard that Lonny was going to sell off most of his shop. I went to the auction and was discouraged to see the number of bidders and the kind of money they were throwing around. I hoped to find an anvil and had my eye on one particular anvil but when the bidding started it quickly became clear that I was out of my league. Then, by a small twist of fate and a bit of luck, I ended up buying the very last anvil. And, it was the same anvil I had been looking at from the start. I initially felt a little dirty about the idea of buying someone’s things after a such a tragic loss. But, my friend told me that Larry would have liked the idea that a new smith got his anvil. He wouldn’t have wanted it to end up in some lady’s garden. So... If you ever visit my garage, there’s a little bit of Larry there. I think about that every once in a while when I’m working.

-

I’m shopping for some tongs. I’ve seen dozens of websites offering all sorts of tongs for blacksmiths and a few of them mention that their tongs can or can not be adjusted for size. My question is, what should you look for to know you’re getting a solid pair of tongs that you can continue to use and resize for a good long life? Is if the size of stock they came from? Is it the metal they’re made of? Is it the size of the boss or the rivet?

-

I’m in S. Idaho and have family in Utah (SLC). I’m on Craigslist, Facebook, and local classified ads. I hit auctions, flea markets, estate sales, you name it. In the last 2 years I’ve only seen 3 or 4 for sale anywhere.

-

I’d need to clamp larger stuff. I have a little bench vise that I can use on thin/small stuff. I have not considered making something but that interests me. I’ve never seen DYI options If I was going to buy something, I don’t know what to look for. I’ve looked at old Wilton vises and stuff but they can be as much or more than a leg vise.

-

The title says it all. I need to clamp hot things and then bang on them with a hammer. I can’t seem to get my hands on a leg/post vise for a reasonable price. What would y’all recommend as 2nd best?

-

Looking at the local FB marketplace I saw this old 34” saw blade for $100. Assuming it’s good steel, how much would you pay for it?

-

Once again, you all are awesome for sharing your knowledge. Kozzy: I’m near Twin Falls. I don’t see many of these around here. I’d love to be back up in the N. part of the state. I see stuff like this from tiny places like Troy or Lapwai all the time.

-

This thing has been hanging around on my local Facebook marketplace. She has come down $50 from $300. At what point is it a buy (i.e. what is it worth)?

-

Thank you all for the replies! I’ve been off line for a bit with work and was very happy to see a bunch of suggestions here now that I’ve got a little time to go back to the garage.

-

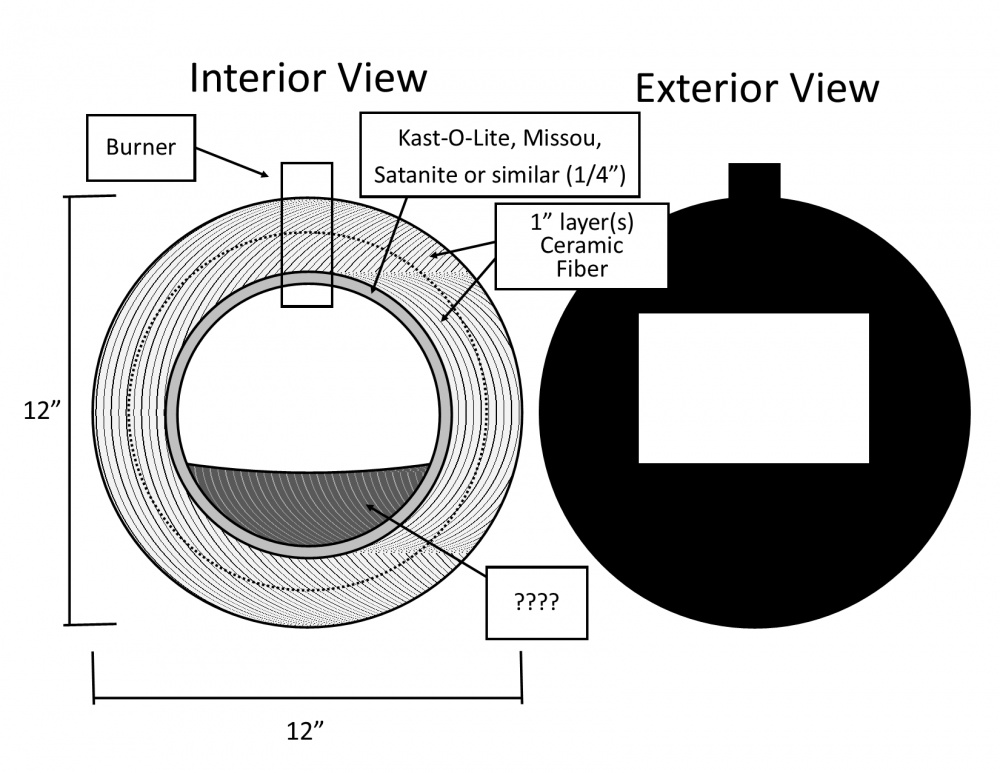

I'm making plans to pull the old lining out of my forge and re-line it. The attached diagram is the basic layout. I'll do 2" of ceramic fiber and then I figured I'd coat the inside with about 1/4" of Satanite or something similar. The big question I have is about the floor. Right now, there are a couple of fire bricks sitting in there. This works well as it brings the floor up to almost level with the openings in the front and back of the forge. But, when I do anything with flux, it runs off of or between the bricks and gets into my forge lining. So here are my ideas: 1- Make a floor out of a castable. Unfortunately, this will not be easily replaceable AND with it being about 2" thick there are issues with it sucking heat. 2- Just use bricks (like I have been doing) but use a castable/refractory that will resist flux for the 1/4" coating. 3- Use bricks and a flux-resistant coating AND put a layer of kitty litter or sand or something in the bottom to "soak up" flux and then sweep that out occasionally. I'm particularly curious about # 3. I keep hearing about people with vertical forges having "kitty litter" in the bottom. Why wouldn't this work in a horizontal forge? I would think it would also help to keep my fire bricks level and in place (not that they move much now). Please share your thoughts or advice. Thanks!

-

You know that feeling when you realize that you’ve been walking around with your fly down since you walked out of the bathroom 15 minutes ago. I’m having that now. In my haste to see if it worked, I let it air cool to black and then dunked it in the water barrel so I could handle it. Then I hit it with a wedge. So... My problem is a combination of impatience and stupidity. Maybe I’ll get a chance to try again this weekend.

-

Where are you in E. WA? t seems like it’s easier to find stuff like this up in the panhandle and in E.WA. Yesterday I saw a listing for a vice in Troy, ID for $75. I was thinking about reaching out to a prof from law school (who lives in Troy) and seeing if he’d pick it up and hold it for me. Then I’d have an excuse to drive up there for a weekend. Man I miss the Palouse. I think I’m going to offer $100 and politely inform them that they’re way above market rate for something used.

-

It may be because I’m not what you would call “mechanically inclined,” but I can’t picture what this would look like (and Google isn’t helping). Can you explain it as though I were a moron? EDIT: xxxx iPhone. There are like 50 pictures in the anvil category.