-

Posts

132 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by foundryguy

-

Yes, they are 65-45-12 ductile iron. They ask me not to discus pricing on this forum site. Shoot me a private message. JLP, I need to check with my son on that. I will get you on Monday. As always, thank you for your support!

-

-

We took care of it for the most part. We have sent a couple to Oregon and would be happy to send another. Get in touch anytime

-

The shank is only going to be offered in 1 inch, at least for now

-

Doug, not sure pricing yet. I do not want to speculate on line either as it causes issues. We need to dial in packaging. There is a good chance there will be a discount with 2 purchased as we hope to get 2 in a flat rate box. Shipping is always the tough part on heavy items

-

-

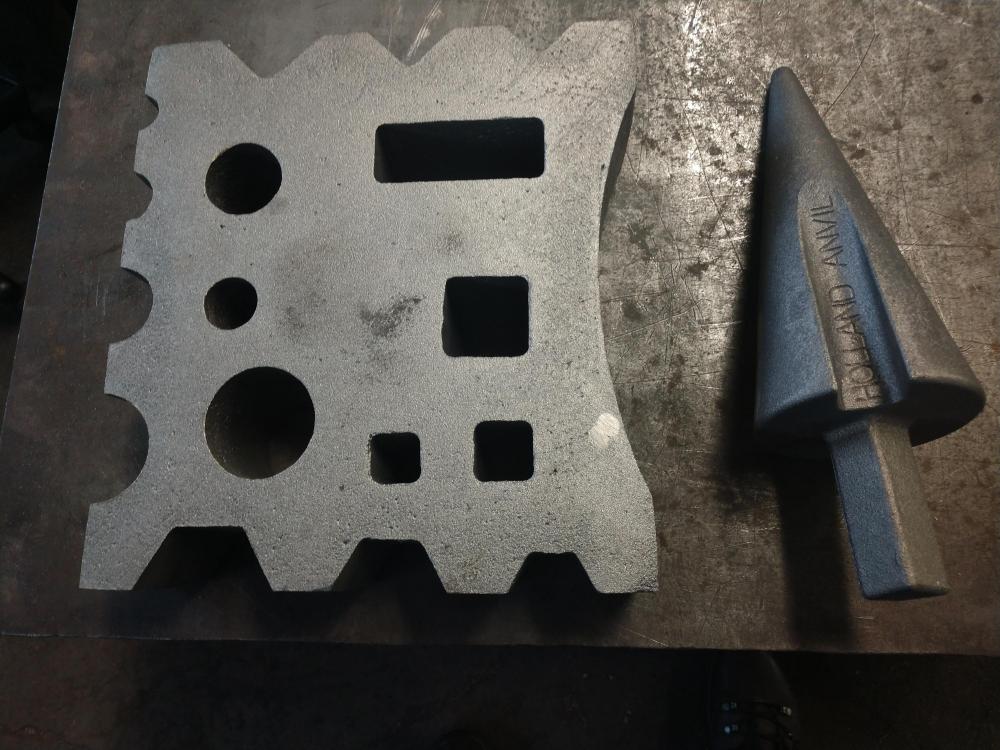

Thank you. I had my son do the mane with recessed letters in a pocket so they can not easily be ground off. Swage Block Duc-2 pics should be posted this week!! Stay tuned

-

My son is going to put one on ebay for $200 in hopes it takes care of some of the re-sellers. I would rather the end user buy them at the OEM price we are charging. Its a work in progress!

-

We have had several people buy them for $175 delivered and resell them for a profit on Craigslist and Ebay. It bothered us at first but it is something we can not control. Several people have told us they found us through someones ebay add so it all works out. We appreciate the compliment as we are trying to bring an affordable quality product to market.

-

smart

-

We are considering a website but don't underestimate the power of Facebook, it works better for us than you can imagine.

-

Yes, I know the numbers and locations. My son decided to keep the price at $175 as this is his design and he takes care of shipping while in college. I guess I should just let the market go with it. I feel bad for those that overpay. Cheers,

-

The name is clearly printed in the description and you can see it in the pics. A google search brings you to our FB page as the #2 suggestion. If I was a buyer on Ebay I would find the OEM in about 3 seconds to check the price, same as a website. Part of me says, let the buyer beware, another part says to the sellers, be up front with us?

-

selling for a $75 markup from what we can see. Asking $150 over delivered price. I probably get some advertising out of it but if I wanted a middle man I would hook up with one of the many distributors that have asked to sell my products.

-

I try to bring blacksmith items to market that are high quality and affordable or should I say priced fairly. Now we have a few people reselling my parts on Ebay, some at an 80% mark-up. Thoughts?

-

Sir, I understand not having a website is an issue. I run a pattern shop and foundry and anvils and blocks are a very small part of what we do everyday. Having a page on facebook is free and simple to use. We are thinking of doing a website but we are often out of anvils and freight is a huge issue, every locations is a different freight rate. If you have any questions on products please contact me PM here and I will be happy to answer any questions you might have. Our next block is drawn up and we just need to cut the pattern. No plans on cutting a pattern on a shovel but who knows?

-

I have the pattern all drawn up but still need to cut it along with the core boxes. It might be a month out? I have some new Anvil patterns being made along with the Sawyers anvil so watch for updates.

-

i saw this photo today. Beautiful work but cracks and broken edges on the block. Design and material selection is important

-

Cutting our 14 inch block pattern today,

-

Largest vintage anvil

foundryguy replied to Timber Ridge Forge's topic in Anvils, Swage Blocks, and Mandrels

Respectfully I would say the Nimba style would be simple to cast in the foundry. With a large mass like we are talking about the metal can chill as it travels across a surface in steel, smaller surface less issues including the shelf. On a one off, prototype, the simpler the design the better. That said, i would take my CAD data from my double horn and just expand it to get my correct size and weight. The pattern and the pour are the easy part, finishing is time consuming and hardening expensive. On our double horns we could see issues running out to the tip of the horn, the other end is think and simple out to the point. I appreciate your interest and will keep you posted but I have been thinking about this, saw the post and had to say something. I could do a big cast iron anvil simple and quick but I do not want to stick my name on it, 200 years from now they will say i make junk. Cheers -

Largest vintage anvil

foundryguy replied to Timber Ridge Forge's topic in Anvils, Swage Blocks, and Mandrels

Marc, I would use a foam pattern to make the casting itself. We use them often, remove the foam and you can not tell the difference between a casting with a foam tool or hard pattern. It is very common in the casting business for one offs or short run items. I will not be making anvil replicas anytime soon, only the real deal and 100% usable. I have been thinking about this for a while. I would make it a double horn, not sure about a shelf as its something that could go wrong in the casting process. Finding a grinder or a mill to handle it would be something i would need to figure out. Busy now so it will be down the road. -

Most we had seen were $5 per lb so we thought $3 plus shipping in a flat rate box was a fair deal. The bigger one will need to get shipped on truck so things will be more complicated and a bit more expensive.

-

actually, we may modify that side and put several half hexes. The block is 3 inches thick. My son is drawing up a big block this week. On the H13, several folks have made requests for it so it might be a luxury item we could make for a couple folks that want it.

-

We had several people request this design and weight. Affordability was our main goal, simple and quick you might say. Thanks for the support.

-

Largest vintage anvil

foundryguy replied to Timber Ridge Forge's topic in Anvils, Swage Blocks, and Mandrels

I would cut a foam pattern so 1 pc would work. I see you are in Australia, shipping is impossible from what I have seen