-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Hunter Copelin

-

-

Hey y’all, I was hoping I could get a hand full of opinions out of everyone.

I recently acquired a pretty big probably near 300# Vulcan anvil from my grandfather-in-law who recently passed very suddenly and left it to me.

I have other anvils but this one would be my biggest and would be sentimental to use, but I’m concerned if I use it, I could damage it pretty badly rather quickly. I’ve never seen a face missing large pieces like this with cracks here and there.I haven’t found any serial numbers yet. But I was whisked away to the lake before I go to do anything outside of a little wire wheeling and a couple pictures.

Anyone ever beat on a face looking like this and continued to removed chunks?it’s not like I’m gonna be using a big ol sledge. I mostly make blades and have a press that does almost all of the heavy lifting anyway.

-

Oh wait... I get it...

-

Are we talking about hammer size, Or arm size now? Hahaha

-

-

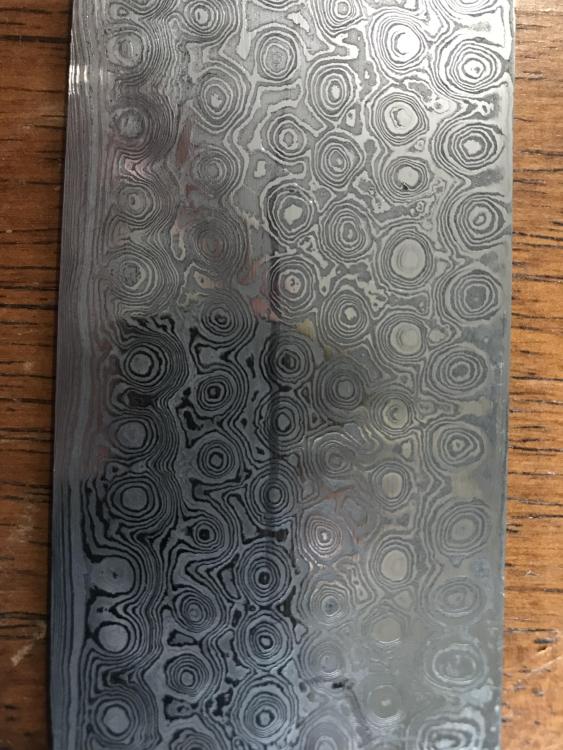

A friend of mine bought me a beautiful billet for Christmas. It is a ton of metal!

This thing is 3/16 thick, 2.25” wide and 10” long.

Honestly, if this was 1095 I would think I had conservatively 3 knives worth of steel here, but this thing already has the pattern perfectly made out on it. If I Forge this into a couple knives will I ruin the raindrop effect? Or could I potentially make it into an interesting smashed down personalized raindrop billet? Ooorrrr would anyone advise I just draw a full tang 10” knife on it and hit the grinder?

-

Bryson: I did the grinding and gave them to him. I ground them and then used electrical tape to show him where I wanted them. The only thing between them should have been some sharpie labeling them with 1’s and 2’s

Thomas: Hahaha guess he drove around in more of a submarine than a car at that point eh?

To everyone else that helped, apparently I did get the billet welded up! I think my blows were more focused on the center, where I could see would cause the edges to curl up and away from each other, even microscopically! Forge welding is definitely one of the coolest things I’ve ever done! Metal is magic!

Thank you all!

-

If that is just a little bit of edge delamination, should I try to fix it, in your opinion, Or just grind it off?

I will I’ll be working on a door too. That’s great advise.

-

Wow. I had no idea. I almost always forge outside, and stand upwind because I didn’t want to breathe the propane fumes, but I have a solid insulator that I used to build my cast iron sink coal forge.

i recon when I get home I’ll be getting rid of that stuff pretty quickly. I sure appreciate that!

-

-

I have a hard time truly knowing what my temperture is in the forge. Surely that’s my biggest problem.

What do you use to tell the temp of your forge? Experience? Haha

-

There is a group called the salt fork craftsmen in Oklahoma here, and I was thinking of going to one of their meetings and seeing if someone wanted to show me a thing or two, but I would hate to show up and impose my problems upon them... maybe I’m just a little shy haha

-

Believe it or not, my very first attempt at hand making some Damascus didn’t work perfectly. So here I am looking for someone to help me through this!

So I’m using a single burner propane forge, one side is blocked off by a half inch thick metal plate and the other side is slightly contained by some red house bricks. (I’m wondering if that’s my problem over all)

1.) Had a buddy weld together together a few pieces of 1080 and 15n20

2.) Got things to roughly 1600 degrees, and applied 20 mule team borax to the sides with the edges.

3.) Back in the forge to what I would honestly call roughly 2000 degrees. (In the daylight of sunset, the forge and stock were almost entirely white)

4.) Over to the anvil with some relatively firm blows. Turning it over a time or two.

Didn’t really know what to expect or feel particularly sure of anything going on, so I repeated the process without borax.

After I ground one of the edges, it’s basically entirely delaminated. Hoestly delamination is probably the wrong phrase because it was never laminated in the first place.

If anyone had any quick tips or fixes it would be awesome! I know how much knowledge is on here and I’ve learned a ton from all of you already!

-

On 10/15/2018 at 6:17 AM, ausfire said:

Heavy equipment trailers use these to help you lift the door on the tongue of the trailer, up at the front. They’re tucked up in there but there could be 2 to 4 on a trailer!

-

I hadn’t thought about the fact that if I change the diameter on a pulley all of the measurements would be off.

Why did you choose to do it that way instead of just being able to correct it with the tentioner?

-

On 11/2/2017 at 9:14 PM, Brian Evans said:

Ok I am getting a better idea of what I should be looking for when I am building it. I may end up adding a three step pulley to the design later if I need to. For now I want something that doesn't take as long as a hand file. I am going to have my drive wheel 5 and a half inches in diameter.

Pardon my 1 year later question, but when you put in a step pulley, you have to be able to track it side to side right, so that you can line things up closely?

Its not like the chain on a bicycle that can just be off to the side a little as you change gears, right?

-

1 hour ago, ThomasPowers said:

there was no need to quote the entire previous post

Lucky for me I do find reading (not all but)a lot of these threads to be slightly more entertaining than rolling a rock up a hill! Haha

-

The toilet is where I do a lot of my reading too!

-

Thank you all for your help and suggestions!

there are only 38k posts in the knife making section. I figure if I read 10 or so a day it would only take me 10 and a half years to get them all under my belt. Then at the age of 32 I could start on the sword making threads! Haha

-

On 6/4/2018 at 1:20 PM, Charles R. Stevens said:

Don’t forget the Saltfork Craftmen either.

I keep running into and visiting with different salt fork members here and there and constantly forget to look into going to their meetings! I know there’s a ton of knowledge there I’m missing out on! As far as the few I’ve talked to, they’re always excited to talk to me if I’ve got legitimate questions! You blacksmiths are a pretty friendly lot! Haha

-

Must have missed it. I’ve got patchy service and lose track of what all I’ve covered

I have contacted Alro and they were really the only one that would take to me about what I was looking for. I was hoping for more options, but I’ve just gotta dig a little deeper by myself

-

I could use a little help.

Im a young, new smith, out of tulsa Oklahoma, and I have been doing a fair amount of forging. I’ve been using metals like leaf springs and even started with stuff that I didn’t even know what it was. Like welding stock from a hardware store, and the odd piece I found in a dumpster here and there on a job site I was working on.

The problem lies in the fact that most of them are a flat stock. I personally think that’s kinda boring. There isn’t much hammer work involved there. It’s usually just smacking the handle shape and working the bevel(s) down a bit then you take to the grinder.

does anyone have any suggestions as to where I might come by some round stock or square stock of good quality, so that I might actually begin to make some pieces that matter?

i know a coil spring is kind of a round stock, and would be interesting to work, but is there a business out there that’s reasonably priced that ships out 1” diameter 1095 or any Carbon steels at a reasonable price?

ive got “the complete blade Smith” in the mail on its way and I’m super excited for what knowledge it can bring me! Here’s a little picture of my set up in my falling down shop for your viewing pleasure.

-

1 hour ago, 4elements said:

The color of the rough unfinished wood and that you cut the tree yourself. I once made a chess set by cutting the red from the white. Nice smell too

That chess set was a pretty cool idea... and totally doable!

This is the log I cut from it. I wish I’d of grabbed more, but the rest went to a fire pit. Oh well...

-

52 minutes ago, MastaStan said:

did you really just quote al;l of that for nothing ???

I figured someone out there had the plan on stabilizing cedar. I won’t lie to myself, I would much rather ruin stuff a few times and learn the skill myself than outsource the work! And if it’s my own knife it wouldn’t matter much anyway, but one day when I’m making millions via blacksmithing I should know.

I appreciate the knowledge and the compliment!

31 minutes ago, 4elements said:Hi Hunter, I was born and raised in Oklahoma and have used that wood a little, but note that there are several trees that are called cedar. What you have is actually juniper and i expect it would do fine with proper treatment as was suggested. True cedar like the western red cedar we have here in washington state where I now live, is much softer as is the eastern cedar from Maine. Those I wouldn't use.

So... you could tell from the wood grain? Or from where I am? That’s pretty impressive

-

Had a friend of mine, whom is much more experienced than myself, warn me about using cedar as a handle. Told me if I didn’t get it treated it would most likely crack or move with the weather. I’ve had the completed knife for a couple months and have used it here or there at work. It’s one of my first completed projects as a new smith and the handle seems to be the best part of it. I actually cut the tree down myself. It had been dead standing for a few years. Oklahoma weather is pretty rough on wood, but this seemed to turn into a pretty decent handle.

I’m wondering if In the future as I progress in this craft if I should steer away from it as a handle material.

just looking for a second opinion. Thanks, you guys are great! I’ve learned so much from here already as a young smith.

i spend as much time reading in this site as I can spare, but there are sssooo many threads and posts I’m sure I’ve missed someone explaining the perfect way to use cedar. I apologize in advance if that’s the case and will continue to read!

Help me take apart this old mistreated katana

in Historical Blades

Posted

Hello all,

Knowing I am a bladesmith, a gentleman from church brought me a katana today asking if I knew much about it or if not, to find out what I can.

I called a local dojo and was able to confirm what I had read about the ability to take the blade apart and read basically all of the information there is about this blade.

Based on my studies this blade does not seem to be anything spectacular or rare, but it is a well built blade and I want to be as respectful as I can to the blade itself, it’s maker and the gentleman who now owns it.

is there anyone here interested in potentially guiding me through the dismantling of this sword or pointing me to someone or some literature they would trust with a similar project?

I have brought this question here because most legitimate sword collectors and scholars won’t even read my post if my first picture isn’t of the bare tang of an already dismantled sword.

here are some pictures of the unfortunate blade for fun