-

Posts

436 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by JustAnotherViking

-

-

It has nothing to do with the content, never has.

It's about selling ads. You get more people glued to the screen for longer, they sell higher priced ad space and share a tiny piece of their profits.

Doesn't matter what you're producing.

Occasionally certain 'content' gets removed because their ad partners don't like it, or it's a delicate topic in the news, so they don't want to risk the negative press and loss of major advertising firms.

-

Several online retailers for mild steel such as themetalstore, metals4u, etc in the UK do custom lengths/quantities. For speciality/high carbon steel, you're likely stuck with ebay.

Have a search on Google for local steelholders and give them a call for prices if you have something in mind.

12mm Square is a fairly universal size for starter projects, and a 7m length typically goes for around a tenner from a local supplier if you go and pick it up (bring a hacksaw or ask them to cut it for you)

For smaller quantities, have a look around your local area next time you're driving around and keep an eye out for small engineering firms.

Call in and have a chat. They likely have a load of offcuts you can possibly take your pick from... Just be sure to drop back with a thank you crate of beer and custom made bottle opener, and you'll be set with a cheap/free supply of material.

-

Ask around, find local blacksmithing groups, and you could be surprised what gets kicked loose

-

It was a sight to behold for sure. Tripping over them all across the sheds, couple of shipping containers, and a few huge steel cages with them stacked up.

Quite funny trying to find one to buy 'oh yes, I think I saw a good one the other day in the corner that might suit you'.

It was a 67kg Brooks, half buried in misc car parts on the floor in a huge workshop

-

I'd maybe bid up to £80 - 100 max. Broken foot, hard to tell much else about the condition from the pics.

England is packed full of really good quality anvils, so don't just bid on the first thing you see

Have a look around this site for info on improvised anvils if you're itching to get up and running until something better comes along

-

If you come across something your considering, fire up a few pics from the listing and I'm sure folk here can have a fairly good guesstimate as to the weight based on sizing up things in the background compared to the anvil.

If you do the search, set the distance from your postcode to something half decent, there should be a button under the search bar saying 'set search alert'.

That will ping you an email each day with new listings.

You'll likely have better luck just getting the word out.

After talking to a couple of people, I was put in touch with a guy who had a collection just shy of 300 anvils.

Any listings I came across were either over priced or snapped up quickly

-

Set up an alert on gumtree rather than ebay. The prices tend to be much more sensible.

Be sure to checkout out this thread for an additional method of finding anvil:

They will be hidden away in farm sheds, garages, engineering workshops tucked under a bench etc.

You don't need a huge anvil. Aim for 50kg - 80kg as a good starting point. No van needed for that.

-

If you're wanting to go down the gas route, vitcas sell body soluble ceramic fibre, ridgidiser, and castable refractory.

They're based in Bristol, but postage on the mainland shouldn't be too bad.

I ended up paying 50 quid postage to NI, but overall it wasn't too pricey considering I got two large forges out of what I bought from them.

-

Stuck up a tree with no phone signal

-

Like Abraham Lincoln famously said; 'never trust anything you read on the Internet'

-

Main tip is to follow the instructions of the designs you have mention exactly. They have been tried and tested, and will work well for you provided you don't deviate.

Best of luck with your build!

If you get stuck, a picture speaks a thousand words, so let us see what you've done, what you're working with, etc.

Have fun

-

Apparently some fella called Patrick drove all the sakes off this island many years ago, but it must be some sort of myth, because i've seen several in glass tanks in the pet shop.

-

Congrats to you both!

Now you have two years of teaching her to walk and talk, and the next 14 years to sit down and be quiet.

Exciting times ahead! My main bit of advice, is have a nap yourself at any possible opportunity. The lack of sleep after my own two still haunts me.

-

Can you paste the link to the youtube video?never mind, found it. That's awesome! -

In that case, perhaps you can help me

I forgot my medicine today, so how much do I need to make now to ensure I don't overdose.

-

Found a couple of things around the thermal properties of zinc.

https://scholarsmine.mst.edu/cgi/viewcontent.cgi?article=6105&context=masters_theses

QuoteEvaporation rates of liquid zinc were determined experimentally within the temperature range of 450° C to 575° C

http://theodoregray.com/PeriodicTable/ZincSafety.html

QuoteWhen zinc is raised to a high temperature (at or above its boiling point around 900C), it burns and forms zinc oxide smoke. Like any kind of smoke, zinc oxide will irritate the lungs, leading to difficulty breathing: This is not a dangerous situation and it clears up immediately when you move away from the source of the fumes. People exposed to high concentrations of zinc oxide over a prolonged period of time can also develop a condition known as the "zinc chills", "metal fume fever", "brass-founders ague", or a number of other colorful terms. This involves fever, tremors, and other unpleasant symptoms.

QuoteOn the basis of these facts, I am absolutely convinced, as are a number of expert chemists, metallurgists, and foundry men I've consulted, that melting pure zinc or alloys containing zinc (but not any lead) that melt at or below about 450C, represents no health hazard from inhalation of zinc fumes. Yes, you can definitely burn yourself really badly if you spill it, but that is the extent of what you have to worry about.

https://www.doctorfire.com/flametmp.html

Quote- Slightly above the base of the fire begins the continuous flame region. Here the temperatures are constant and are slightly below 900°C.

- Above the solid flame region is the intermittent flame region. Here the temperatures are continuously dropping as one moves up the plume. The visible flame tips correspond to a temperature of about 320°C.

- Finally, beyond the flame tips is the thermal plume region, where no more flames are visible and temperature continually drop with height.

QuoteIn studying fires in a warehouse storage rack geometry, Ingason [9] found an average solid-flame temperature of 870°C. At the visible flame tips, the average temperature was 450°C, but the range was large, covering 300~600°C.

Based on the above, i'd surmise an average open fire, even at the edges, has the potential to reach the zinc evaporation point, thus making it dangerous (although not fatal).

I've read the first sentence on the Dunning-Kruger wikipedia page, so obviously i'm an expert.

-

2 hours ago, JHCC said:

dead hot water heater

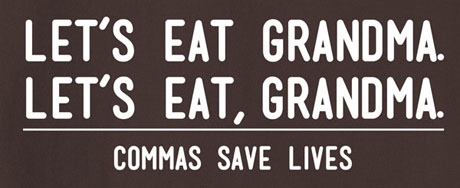

Is that a 'dead hot, water heater', or a 'dead, hot water heater'?

-

9 hours ago, tonyw said:

Just a tip,

If you dip your finger in a mixture of dish soap and water, you can tool a bead of silicone without it sticking to your finger...

I shall have to give this a go. I tried to silicone seal a big galvanised bin to hold water, but ended up with more over my gloves than on the bin... either way, it didn't stick or seal at all.

I tried a high temp silicone after the first failure... it did stick to the bin, but dissolved in water... go figure.

Third times the charm? right???

-

Quite a lot of money for all you get.

Cheaper to make your own.

The ceramic fibre comes uncoated, and a friend who has one has a lot of trouble getting both burners going at the same time.

Lack of front/back door also wastes a lot of heat.

All in all, not great.

-

Want me to post it to you for the missus? Siphon some of her yarn funds into your tool funds... What I've heard of this breed, there'll be plenty to spin

-

I have been scouring reviews for recommendations on the best brushes for them as I have heard as much.

For now we just picked up a small slicker brush to get him used to the idea of it. Still has puppy fur, so no shedding yet.

So glad to have finally found a dog compatible with asthma, allergies and children.

Shall just have to embrace the fur life. Small price to pay

-

Brought this little guy home today

Two months old samoyed.

Such a friendly calm natured dog. Him and my daughter bonded in seconds and he spent the rest of the day following her... So much for getting myself a dog.

-

Is that not right around the tempered martensite embrittlement realm? (please excuse my ignorance, genuine question)... I was (most likely incorrectly) under the impression that once you go that far, it's borderline needing to be heat treated again because it's quite easy to dip past the point of no return at those temperatures, hence the comment about a controlled heat treatment oven rather than eyeballing it by color? (I suppose a lot depends on the alloy in question also)

-

I assumed that taking it up to a blue (over 500f) would be tricky enough without loosing the hardness to the point it was worth doing in the first place?

i.e. hard to stop the temper at that point by flame, and ovens don't tend to get hot enough?

I shall go and read.

Forged Rocking Chair WIP

in Member Projects

Posted

Stunning work!