-

Posts

6 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by James Conyers

-

-

2/2 for good advice. Thanks Frosty!

I'll check out the forges page.

-

Thanks for the info. I'll check it out!

-

Thanks for the words guys! I'm still on the process of putting the basic stuff together. I posted a question over in the gas forge section about the build I'm thinking of doing (forgive the drawing of you head over that way). It's nice to know that this community is so welcoming. I'm sure I will be posting a boatlode of questions on the coming weeks.

Kampai!

Big Jim

-

Hello again,

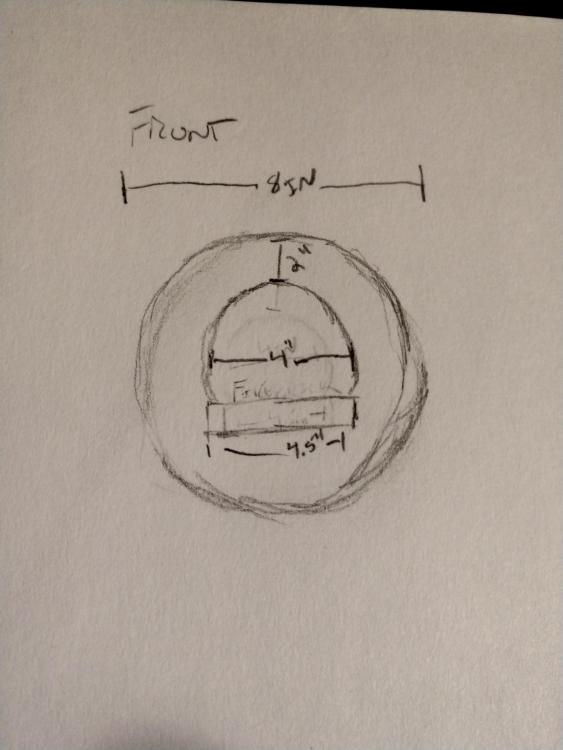

I've had some time to do research on different kinds of refractory material and I really like how the Kast-O-Lite 30Li sounds at first glance. I was wondering if I should coat the Kast-O-Lite in an IR refractory like ITC-100 (a little too pricey for me...) or Meeco's Red Devil 610 refractory cement (well with in my price range but unsure about efficacy). I have attached a ROUGH drawing of the front of the forge. Here is an overall idea of what I'm shooting for:

Brushed stainless metal trash can for the shell (H=12" Dia=8")

Hoping to do 2" of Kast-O-Lite to make a chamber of about 4" x 11" and have an exhaust port at the rear about 1.5"

Hard fire brick as the floor (4.5"x9"x1ish") No refractory on these.

Planning on having the burner pipe cast with the material then holding it in place with bolts.

What say you fine folks? Any and all wisdom is greatly appreciated. I'm hoping to get this bad boy up to welding temps but we'll see.

As always thanks for all the advice.

Cheers!

Big Jim

(p.s. please excuse the horrible drawing in the image... I swear my 6 year old can draw better than me)

Oh and I was also thinking of using the lid as a door to make the front opening smaller to retain more heat when I'm trying to weld.

Kombae!

Big Jim

-

Well here is my first post...

I'm about to start the journey of iron working and I feel like my head might be to high up in the sky too think about the negative impacts of this new hobby. I would like some advice that will keep me rooted in the real world. But let me tell you where I am now:

I helped a friend work some steel a few years ago and I could never shake off the longing to do it again. I've moved twice since then and will likely be off to the other side of the world before to long. I've read tons of books and watched hours of videos. I picked up a railroad track anvil for $20 and plan on making a trashcan forge (gas) this weekend. I plan on making small things first (arrow heads, small knives, etc.) to start and use that experience to learn the trade.

I would like to keep my smithy as mobile as possible as moving is still in the cards for at least the next 6 years.

Do any of y'all have advice for a novice metal worker?

First projects? Ways to develop basic skills? Is this railroad track going to be enough? Should I even bother?

Thanks for the help.

Big Jim

Swage Block Substitute

in Swage Blocks

Posted

I'm still pretty new to this obsession called blacksmithing and I recently picked up a drop of steel to beat on until I can afford a real anvil (There's aplace I've been using that has a full shop). I don't have a hardie or pritchel hole but I would like to start punching and drifting at home as it is far more convenient than driving for 45 mins each way.

::Sets out coffee, beer, whiskey, and snacks to appease the curmudgeons::

For a new guy what would you recommend for this task? Budget is EXTREMELY limited, kid #2 is about 6 weeks from making his world debut.

I have a fried that has a plasma cutting table and a MIG welder. My initial thought was to get another steel drop and some angle and rig something up short term.

What say you fine folks?