Drego

Members-

Posts

14 -

Joined

-

Last visited

Profile Information

-

Location

Thunder Bay, Ontario

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

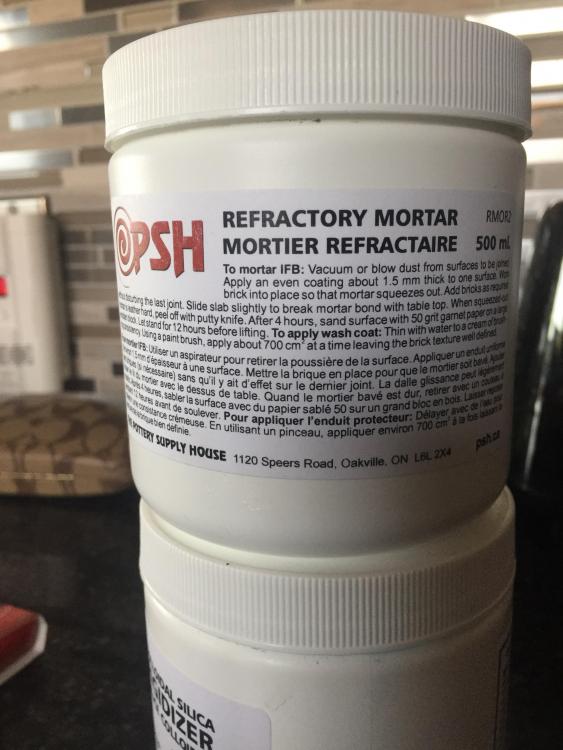

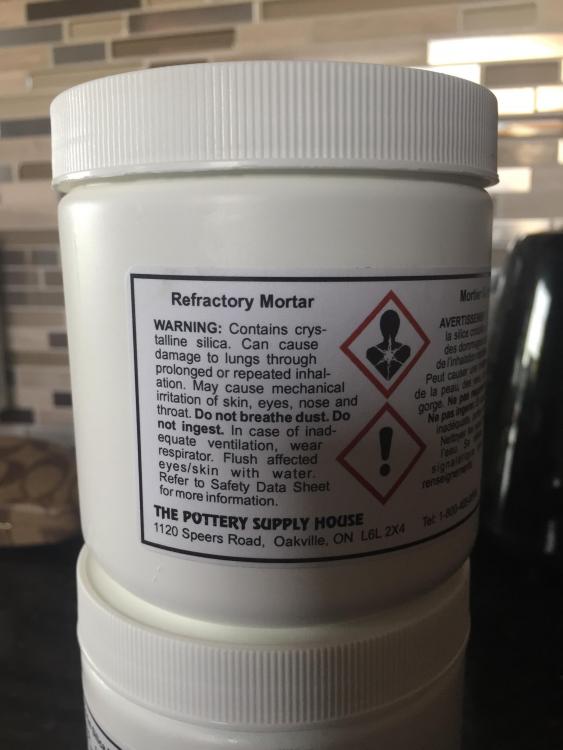

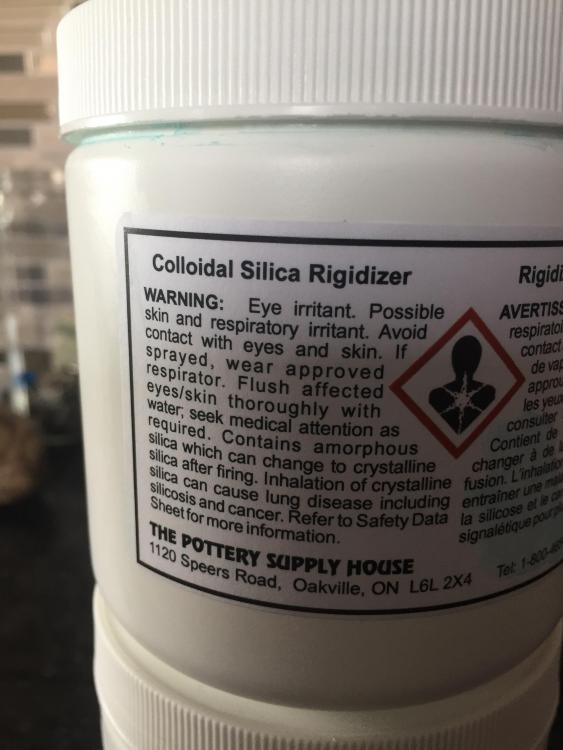

It's from a place called pottery supply house. Looks like it may be their own blend. Gonna see if I can find the MSDS on it if there is one.

-

I knew there are lots of recipes for "home grown" rigidizer and other things. But it was $9.00 for the pint I got so no huge deal plus I have never done this before so I'd rather go with a known product then something I've tried to mix together. Any ideas as to what thickness of refractory I should be applying?

-

Hey there, I tried searching the the forum and read through the stickies. Found lots of info, mostly technical stuff that is good information but isn't exactly what I'm looking for. So here goes. I have a majestic 2 burner knife maker delux forge that I pooched the liner in the lid on. I picked up some Kaowool 1", rigidizer and some refracrory mortar from a local pottery supply place. I suppose a little back story is due. The liner that is in the forge developed cracks in it. I tried sealing the cracks but used the wrong material which ended up eating into the liner. So I cleaned the wrong material out and used some imperial high temp stove and furnace cement to seal up those cracks and areas where I cleaned it out. Pictures are below. So now I figure I'm going to scrap the liner that's in there and try and replace it with the Kaowool. Rumour has it that the kaowool will be more efficient then the current liner that comes in the forge to begin with. Dimensions of the lid are 13 3/4" x 9" x 1 1/2" On to the questions I have. 1. Should I "glue" the first layer of kaowool to the metal lid or try and friction fit it to the lid? If I do glue it then with what? 2. Do I apply the rigidizer to the first layer of kaowool, or put both layers in then rigidize? 3. If I rigidize layer by layer, then do I need to fire the forge layer by layer to "cure" the rigidizer before applying the next layer of kaowool? 4. After the rigidizer is cured do I apply the refractory mortar to it? If so how thick? If let's say 1/4" thick do I apply the mortar in layers or just one 1/4" thick application? 5. After the mortar, do I do a wash coat of mortar on top of that? 6. Burner holes. Should I apply the mortar to the circumference of the burner holes to protect the kaowool from flame? Sorry for the long post but I've never relined before and want to do this correctly the first time. Also I haven't been able to find a step by step on the forum. Couple of notes with the pictures, the imperial cement pictured is not the same refractory mortar I picked up from the pottery place. The dark grey cement versus the light grey is just that the darker stuff was applied after firing the forge with cement already in it so it's "uncured" Thanks, Dennis

-

Both things I do not have. Pretty handy with a grinder n cut off wheel though.

-

Emailed them. Really helpful. Aparantly used the wrong stuff but picked up the correct stuff today and have it on curing.

-

Alright so about 5 minutes of hammering got me here. I think it will be ok steel to move time will tell have an issue with the forge now it's a majestic two burner upper liner had some cracks which is normal I guess but I decided to seal them as per the instructions that came with the forge well the sealer I got appears to be eating into the liner I think I'm screwed

-

Got the pins. They're about 11/16" thick and 3 5/8 long. It didn't take as long to cut through them as I thought it would. Gonna put some heat to it and see what happens.

-

Sweet. Thanks!

-

Nope no special deals here. Just have it available but have to figure if the cost of NG is cheaper then propane. Just got my NG bill. Used $4.00 in gas (range, hot water, furnace) but my bil was almost $40.00 once you factor in all the fees. I have one of those exchange-a-tank propane tanks, so have to see if it's cheaper to get it filled or exchange

-

Tongs, punches, hooks, gonna try some leaf keychains. Basically anything I can practice building skills doing. Eventually when I'm comfortable in my skills I'd like to try and make a knife. Don't foresee it for a year or so but until then, just practicing. Would like to try forge welding too. Baby steps tho.

-

Thanks for the insight. I'm not 100% saying I want to use the natural gas it's more like it's there so why not. But you seemed to answer the why not. Im going to swing by my buddies work tomorrow (Kenworth dealership/shop) and pick up the pins. I used to work there myself and they all like me there so they said I could have free reign on the scrap steel bin. Anything in particular I should be on the lookout for? Axles, springs, etc... Dennis excessive quote removed

-

Good point. I'm gonna try one out and see how it forges. All I've pounded on so far is rebar so I'm sure I'm in for an eye opener. But if it anneals well and forges well then score! If not then as you said maybe someone with a power hammer would be willing to trade fro so,etching else more my "size".

-

Wow quick replies! Not looking to make anything in particular YET with them. Just wondering what they'd be like to forge if anyone has experience working with them. I get what Matthew is saying tho. I'm going to first try and cut one into lengthwise quarters and heat it up and see how it reacts to the hammer. Then I'll try another piece and heat it then let it cool (annealing?). Do that three times then see how it takes a hammer. I figure punches, would be a good starting point but that amount steel would make a lot of punches lol. My my shop is detached from the house. No natural gas in it yet but I want to hook up the infloor heating so I'll have to eventually run a gas line from the house to the shop. Thinking to my self so long as it's already there how bout running the forge of it as well.

-

Hey folks. My my first post here so a little introduction is in order. Im just getting into the craft. I picked up a Majestic 2 burner propane forge and am quite happy with so far. I have only really been using it on one burner since it gets plenty hot it's just the one by its self. I don't have an anvil but am constantly on the lookout for one. In the mean time I'm using a ASO (Railroad track). I have a couple questions to start. 1. What are thoughts on using natural gas instead of propane to heat the forge? I believe natural gas gets hotter then propane. Although I'd have to crunch the numbers to see if filling propane tanks would be cheaper then using natural gas. 2. A friend of mine has 14 piston wrist pins from a Cummins ISX engine for me to use. The best I can find is that these are made from a Chromium, Molybdenum, Nickle alloy. I think this puts it in the 43xx class but am not sure. Has anyone worked with it before? They are big so I'd be cutting them in half at least. Thanks! Dennis