Binesman

Members-

Posts

327 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Binesman

-

Greencast 94 refractory questions

Binesman replied to Zachary's topic in Insulation and Refractories

Zachary. Yes sand. -

Check local scrapyards for suckerrod. Look in to farrier supply stores in your area (horseshoes are great for getting the imagination going) some will order steal for you and some will already have blacksmithimg steal on hand. My local carries s7 and 10xx series in roundstock.

-

Greencast 94 refractory questions

Binesman replied to Zachary's topic in Insulation and Refractories

Straight 20muleteam borax will do the trick frosty. Turns the kastolite in to a sticky glue like substance. -

Yes and yes. The most fun was watching the 3yo say "papa me made sharp you carefully" as he wagged his finger.

-

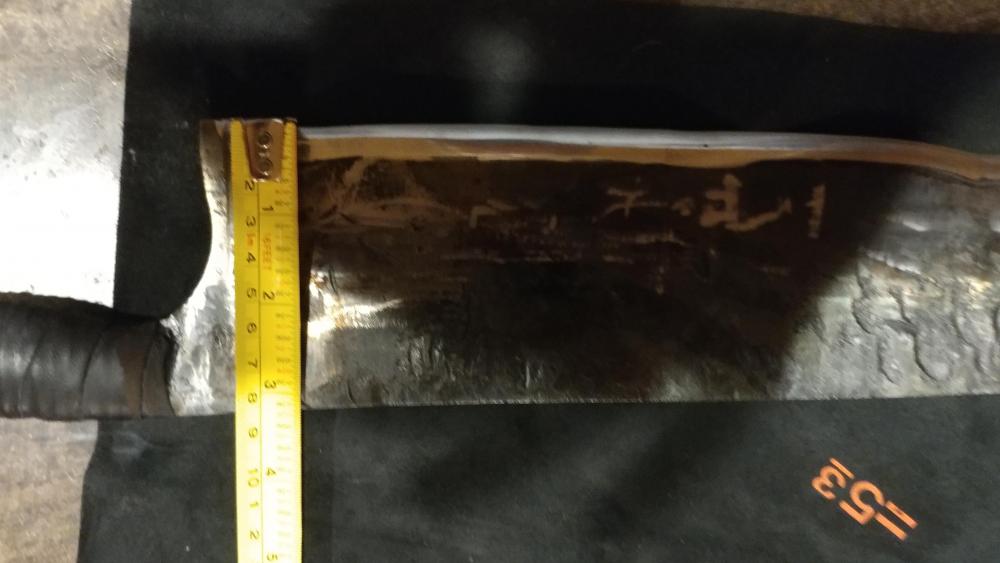

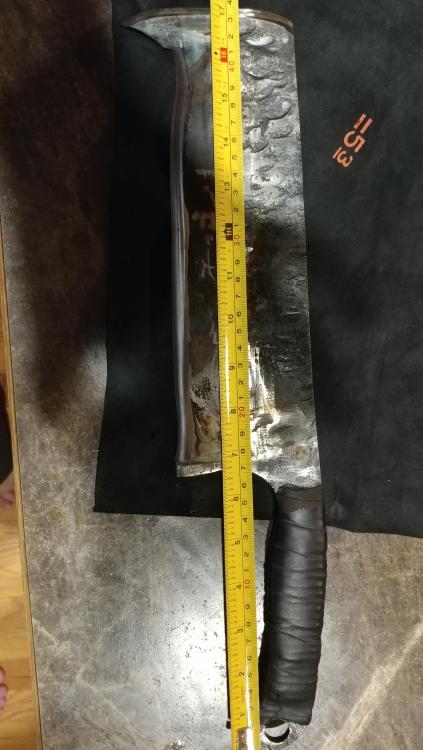

My 10yo decided he wanted help making a skinner for my father in law for fathers day. He then decided the 6yo and 3yo had to help so it turned in to a bit of an ordeal. However I think they did pretty good for only a week late.

-

Order to layer bricks and kaowool

Binesman replied to Darthpinkeye's topic in Insulation and Refractories

9 x 4.5 x 18 is around 720 cubic inches. in my oppinion that is to large to use brick. I guess the question is have you already purchased enough brick to make this? If the answer is yes then use brick as your shell with 1" of kaowool on the inside (you can use 2" but that may be overkill as the brick is also insulating) coat that in 1/4" kastolite30 (3/4" on the floor) and coat that in a layered of matrikote. If you dont already have the brick use some sheet metal to make your shell and follow the above instructions (using 2 1" layers of kaowool) -

Heres my advice for that price point. Buy him a box of 8 k26 insulating firebricks, a 50lb bag of kastolite30, a pint of matrikote90ac. Then tell him to come her on instructions to put it all together and build a burner. All of that will be in the 200 range. Anything other than that will cost a lot more for something decent.

-

Burner Flare within the Forge, and Propane Plumbing

Binesman replied to ADodds720's topic in Gas Forges

Here's my question. What do you intend to use the forge for? I see this constantly with people I talk to that are new. "Oh im going to get a 24" long 3 burner forge" why!? Dont get me wrong they have there purpose but most peiple dont need anything of that size. So if money is a factor look to making a smaller more reasonable forge that will cost substantially less now AND in the future. -

100% agree the thing no one takes in to consideration with DF or many of the other "cheap" brands is they are not turn key. You are basicly buying a very expensive shell.

-

Beginner looking for feedback on 2-burner forge plans

Binesman replied to Bruno Medeiros's topic in Gas Forges

2 suggestions to save you enough you could build 3 of these. 1 switch from itc100 to matrikote 30. It holds up better to our kind of use. 2. Read the frosty tburner pinned thread. They are easy to make and 2 of them is more than enough for that forge. Also what mikey said move your propane bottle when in use. -

Mikey people gotta learn somehow. If there is no one around to teach you go with trial and error. It also helps finding places like this to ask questions.

-

Kastolite is super sticky i dont see you having any issues with it bonding to duraboard

-

Hmm somebody is a much bigger fan then i. Yes that sounds about like the scene i was thinking of.

-

If i remember right game of thrones had a scene of them casting a sword as well

-

Yeah it was a blast a friend and i actualy made it as a gift for a video game company producing a game we are eagerly awaiting. One of the "sides" in the game is a nordic like people so we wanted to make something that looked like it beloned to them and had seen a lot of battle. So we hammered heavy and didnt grind clean then after tempering we put boiled linseed oil on while still hot so it would darken and age the blade then scrubbed it in with scotchbrite pad. To end we only clean/polished the edges to 400grit so eaven though it was "old and battered" it was "maintained and deadly"

-

-

Fumed silica+water mixed to a paste consistancy. Spread on andpush in to the cracks. Wait 2 days then bring forge to a forging temp and hold for 10 minutes. Then kiln wash (id recomend a thin layer of kastolite before kiln washing for further protection but it isnt necessary)

-

Do you have a coupler on it as a flame retainer? Been a while since i read the tburner instructions and i believe frosty taks about it and says it is unnecessary. However in your case it sounds like it is needed.

-

You are correct with being off mark . nock that cement out and put in a 1" lining of kastolite 30. Then put a kiln wash of plistex or matrikote and you are good to go.

-

First I would highly recommend reading the burners 101 threat as for a burner I would recommend building a t burner the instructions of which are pinned here on this site As for forged in fire the burners on their forges are forced air the burners with chokes are naturally aspirated there are also naturally-aspirated burners that don't have chokes realistically unless you were doing very specific work you want a close to neutral flame at all times making the need for a choke unnecessary Based on your question I am assuming that you are extremely new to this Hobby and really haven't done a lot of research I'm glad you wound up on this site first when you build your Forge please do not follow any of these so-called YouTube experts you will simply waste time money and effort to make something that is half workable follow a set design to build your Forge and burner do not deviate from these designs as a small deviation can make a huge difference in performance and I'm guessing that you don't have the experience to understand the differences that will be caused If you google wayne coe artist blacksmith. His website has a forge plan and he sells all of the material to make the forge at a reasonable price as for the burner see above make a frosty T

-

You using a naturally-aspirated burner and as such you have to have some exhaust vent so the door is not touching isn't really an issue what I may suggest doing and what I have planned when I built mine was to have the rear door touch so I could fully shut the rear but I intended to have about a half inch gap on the front door to allow 4 exhaust my intention is also to add a 2-inch by 2-inch "viewing window" in the front so that I can still keep an eye on my work when everything is completely shut up Just spit balling ideas and future plans here i see no need to change your set up to this as the gapping is to a degree necesarry for a na burner

-

Drill some holes and just use a simple pin to hold it in place not counterweight etc needed. If you dont do a lot of long work it probably doesnt matter for me it seems every other project is hanging out the back. By going verticle you could still close off all but a little bit while still keeping your work near the burner flame in the center of the corge over having it jammed up against the side of the forge to still get closure with a horizontal door

-

Gotcha I ask these questions because I've been looking into building a square Forge myself and was just wondering what you were doing. However one thing I would recommend to you is putting your doors on a vertical slide rather than horizontal so that if you were working with something long you can still get maximum reflection with pass-through