JustNick

Members-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by JustNick

-

Quenching Tool Steel Literally

JustNick replied to JustNick's topic in Heat Treating, general discussion

Steve, Actually I have read the pinned notes you wrote and others. but as I stated it is a unknown alloy to me so I figured someone in the brain trust of IFI might have worked with it before. Hence the question. Thanks Daswulf, No not chrome plated. I would not even attempt it if it were. Thank you for your valuable input Thomas, Thanks for your reply that is more of what I was asking/looking for. and yes no doubt I would be testing everything long before I gave a punch to anyone to use. And if it were to fail I would make it a necklace or the like. Thank you for your input Jeremy, I am not trying to "be cool" as you are. Yes I have heat treated my fair share but as stated I always know exactly what the metal is I am working with. And you might be better off making useful replies to what people are trying to spark a conversation about on a internet forum. I may be new to forging but I am far from new to metal working, machining, and common sense, I understand this forum gets a lot of new comers to metal working etc, but some here might need to realize that others might know a thing or two about safety and liabilities before just being out right arrogant in there responses . Bring on the flaming -

I have some old Snap-On tools that I want to forge into center punches my Snap on guy tells me that they use a special steel that is only available to Snap on. So my question is has anyone ever heat treated snap on tools. Now normally I only use new steels that I know what they are and how to heat treat but I thought this would be cool to keep in my tool box and for my employees also seeing as all of us only use snap on tools it would be nice to have hand made repurposed snap on punches. Would I use oil quench ? or water ?

-

Thank You IronDragon It was packed full of grease that's why I put more I have taken it down and cleaned all the old grease off the gears and cleaned the gear housing up check all the gears for any issues and they are all good I will use bar oil as I have plenty of that for the little giant. I have a centaur forge store 20 miles from me and the have the tuyere grill and a bag of coke waiting on me. from the measurement's I will have to modify it a little but that is not a problem. Irondragon I see you are in Eureka Springs me and my girls go up there every June for a week so I can get away and do some riding we normally stay on spring street with eurekazen. Is your forge open to the public ? Its up there that actually got me into Blacksmithing my wife bought me a knife at a mill out side of town and I had never seen Damascus until then and it just kind of spiraled off into a new passion for forging. It would be cool to come see your smithy this june if you are open to the public.

-

Thank you Kozzy I just took it apart to further inspect the gears and there are not chipped teeth on the gears both of the big gears are stamped 69 assuming the teeth count. The bushings don't look to be warn bad but I will measure and replace what I can. For all I know the noise might be normal but I don't want to damage it if not so I will rebuild before I use. This is my first solid fuel forge so I am learning about it as I read here and go. The grate in the bottom of the Tray does have a crack in it and needs to be replace what should I use to make a new one or is there some available to order ?

-

I just got a old Buffalo coal forge and I need to rebuild the gears in it. Once you turn the crank it starts to make a loud howling almost grinding noise but it is not grinding. Is there a bushing/bearing rebuild kit available some where I have looked but come up empty. I have taken the covers off and greased it, it did get a little better but I would like to go thru it before I put it to use. I have attached some pictures to help ID it. Any help of info would be great I was told it is from 1908 but don't know if that is true. Thank You

-

Steve where would one find your book I have looked (quite Quickly) and could not find it ?

-

How do you price anvils ? I am buying a 373lb anvil a 1927 Soding-Halbach einhorn anvil and I got to thinking how do the prices get decided. Now I am happy with the price I am paying for it so that really is not the question but just curious on how it is done. So say I decided to sell my 187lb original PFP military issue anvil how would I decide a price on that one. it is in excellent condition 95%plus rebound rings like xxxxx when not fastened down and not a scratch or chip or anything on it any ware. It has been estimated to be built around 1910 and also thought to be military issue because of the numbers stamped in it. It is not for sale but it is a beautiful anvil that everyone that has seen and used it with me has asked to buy it from me but hell no. The 373lb anvil I am buying is in amazing condition also like my PFP.

-

Thank you all and yes we think it is around 200lbs and the stand is right there with it. I really did not need one yet but I could not refuse for the price I paid. jlpservicesinc It started out because my great grandfather had a old anvil I always liked and wanted so I bought my anvil more to have a nice piece of history that I always have liked then that turned into me wanting to start a new hobby of blacksmithing I plan on making all my tooling I need to be able to make some hammers and knifes. I have already made a 480 layer billet of Damascus and am working on the tooling I need to make some nice hammers. At the end of the day I have just fallen into a blacksmithing addiction and want to do it all the time but Family and work seem to get in my way. But I think I am going to devote my time making hammers some of the ones I see the pros make are amazing and I want to give it a run. I figure I am young enough to be able to make so really nice things in my life. I am the type of person that has to be doing something constructive all the time or I get in trouble. I have been blessed in my line of business to be able to play a little on my hobbies. and I have met a guy local to me that has become a friend and he has more antique blacksmith tools then I could ever have imagined possible that he collects uses and sells and he is a bad influence on me by giving me great deals on some of my tooling. so now I am doing what I can and learning everything else I can and taking classes with blacksmiths to learn as much as possible. I am going to go the Lyle Wynn's Class early next year if I can find time. Sorry I just kind of went off with my response

-

Really No advice ? Wow either people don't care or I am a master on my first set of tongs I ever tried

-

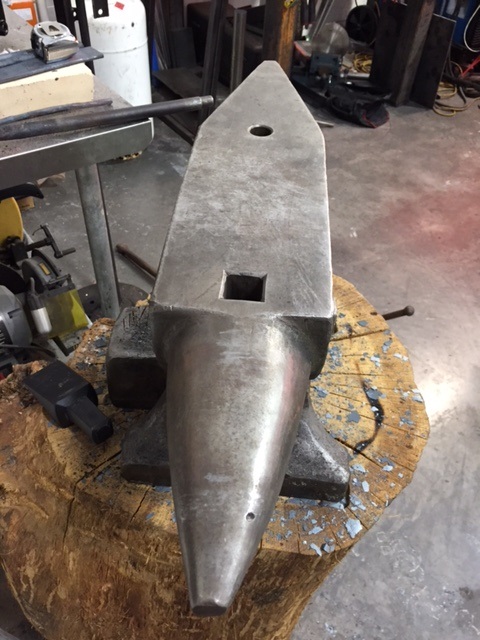

Hello I would like to know more about my new to me swage block and original stand for it. I know there is no way to tell what year ect it was made or by who it was made. But if there is any other way to find out more info I would like to learn more about this piece. Here are some pictures of it. I am excited to own it and I am going to love to learn more about it and blacksmithing in general. I have not weighted it yet but it is 16"x16"x4.5" Thanks Nick

-

Hello I am new to forging and I am going to be starting out making all my tools I need. So the question is this is my first set of tongs a I am working on and they are power hammer pick up tongs or Boca tongs as Brent Bailey calls them on his website. Please let me know if I am doing good or not so good and any input you might have. Thanks Nick

-

I bought this as my first anvil I am told it is from the early 1910's to 1920. I think it is in really good shape and I would like to know more about it. I read the post on Peddinghaus anvils but all the pictures are gone. I would also like to know if anyone knows what the numbers are that are stamped under the logo. I was told they think it was made for the German military and that is numbers they stamp into them. Anyway I am new to blacksmithing and would love to know more about my anvil. Thanks in advance Just Nick

-

Hammer eye punch for power hammer

JustNick replied to JustNick's topic in Slitters, Punches, Drifts, etc

No I wont be using the punch as the drift I will be making one of those also. I figure it is best to make all the tooling needed to make hammers just for practice to get better and learn more about blacksmithing. Thank you for your help you have given me some great ideas. and where is this place in Arkansas I am up there a couple times a year. -

Hammer eye punch for power hammer

JustNick replied to JustNick's topic in Slitters, Punches, Drifts, etc

If you read what I said yes some basics are lacking. And that is why I joined the Forum and I am asking questions and looking to take the class with Lyle. I have been welding and machining metal for years and own quite a bit of equipment for someone that does not do it for a living. I love working with metal and have been using the PH to make Damascus that I will make blades with and I decided I would like to make my own hammers so I am I the process or research and learning how to make tooling to do so. Making tooling is a bit different the ornamental stuff and banging on railroad spikes so there for I will study and learn before I jump into it. Thank you for you input and concern but I am not some idiot that is going to hurt myself or damage a 97 year old power hammer -

Hello I am new to the forum and to blacksmithing. I would like to try and make some hammers with my 100lb little giant but I cant find a hammer eye punch for the little giant. I have seen videos of guys using them like Paul Krzyszkowski just used in his double head axe video on you tube. Where would I find one of these punches for the PH or does some one have the dimensions of how to make one my self. Sorry like I said I am very new to blacksmith work and am trying to learn as much as I can. I am also trying to sigh up for some classes with Lyle Wynn for over the winter if he still is doing classes.