AxL

Members-

Posts

30 -

Joined

-

Last visited

Profile Information

-

Location

Norway

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Took a while, haven't been in the shop for a while. I have already reversed the bevel on the air intake. I can try the enlarged flame nozzle first. Could i make a new jet by turning one on a lathe? It seems quicker than the capillary tube insert.

-

I have not done the math, Mikey did. And there currently is no choke plate, it's running at wide open throttle. Yes I got rid of that, the joint is beveled and near seamless. I'll get a photo in slightly better light as soon as I can.

-

-

I've started a thread about the brick pile forge.

-

I recently finished a 1/2" burner build (see the Linear forge burner plans thread), and I'm looking to build a simple brick pile forge for it. My goal isn't forging as such, just hardening steel. I have a few 9x4.5x1" heavy fire bricks, what would be the best way to stack them? I understand there is a certain ratio between the of volume of the forge vs the size of the burner, what size would the forge need to be for a 1/2" burner? Should it be lined with refractory cement? I assume there are many other things I haven't thought of, feel free to enlighten me.

-

I could probably chuck it back in the lathe and take off .020". It might be a couple of weeks before I can get to it though, I have a lot of work coming up. I also kinda wanna get on to building a forge. I'll see what I have time for over the next couple weeks. I have some 9x4.5x1" heavy fire bricks, could I just make a simple brick pile forge?

-

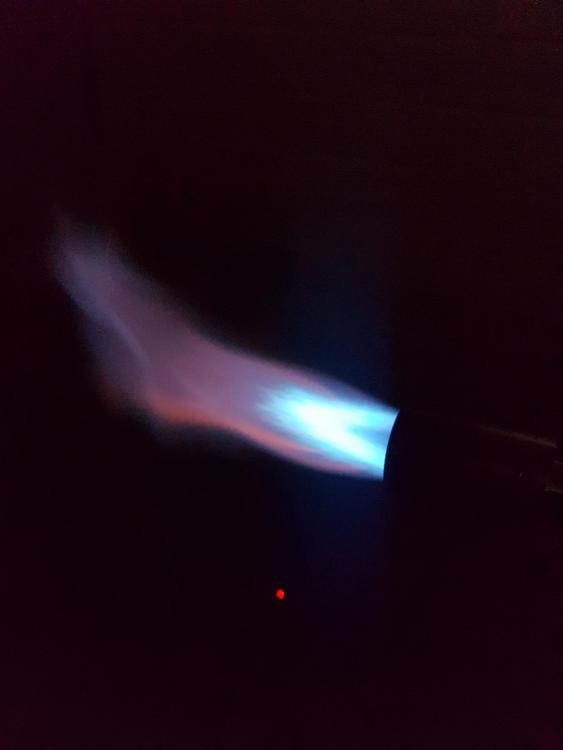

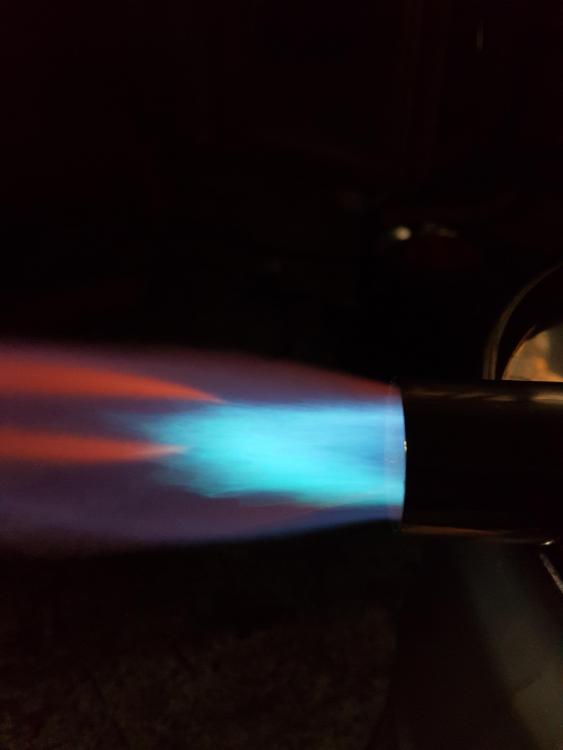

Been gone for a week, so didn't get to this before this weekend. Got the nozzle tuned, and the red flames are gone.

-

It is stainless, but maybe not 316. It might some residue from grease/WD40 or whatever was in the tube when it was used. I pulled it from the scrap bin at work. I'll give the adjusting another go later today or tomorrow. I tested it today on a small piece of steele and it had no trouble heating it to hardening temperature. This is fun!

-

I got a 0.6 mm mig tip and tried it on. The flames blue bell seemed a little different. The outer layer of flame turned red after a while, it seemed to coincide with the nozzle heating up. What does this mean?

-

Mig tip is rated for 0.8 mm wire. Mixing tube ID is 15.5 mm.

-

I made a new nozzle and did my best to align the parts. As far as I can tell (measured with a laser) it's straight and true. I honestly can't see much of a difference in the flames, so either my eyes aren't tuned for this or I have made no difference. Thoughts?

-

I would by no means call it disappointing, I expected nothing like this. I expected to have made som critical error at some point and the burner not working! I'll get started on a new nozzle and try to tweak the misaligned parts back into alignement. I'll try to move the gas tube back a little too, play around and see what happens. Thanks guys, updates to come!

-

It works! That was the best flame I could get by adjusting the nozzle. I might have to redo the gas tube, it should probably be longer. But not bad for a first try! Thanks for all your help and input Mikey!

-

I read it all wrong, i was thinking of the mixing tube! Gonna get it done today and test fire it this evening.

-

It can be moved deeper, like I said in the previous post, it can be moved as deep as the opening of the mixing tube. When you say bevel the end of the gas tube, you mean the end where the nozzle sits, yes? The business end? The end that's attached to the reducer is already beveled. Is 60 degrees the correct bevel?