-

Posts

276 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by GrumpyBiker

-

Show me your Bottle Openers!

GrumpyBiker replied to Arbalist's topic in Blacksmithing, General Discussion

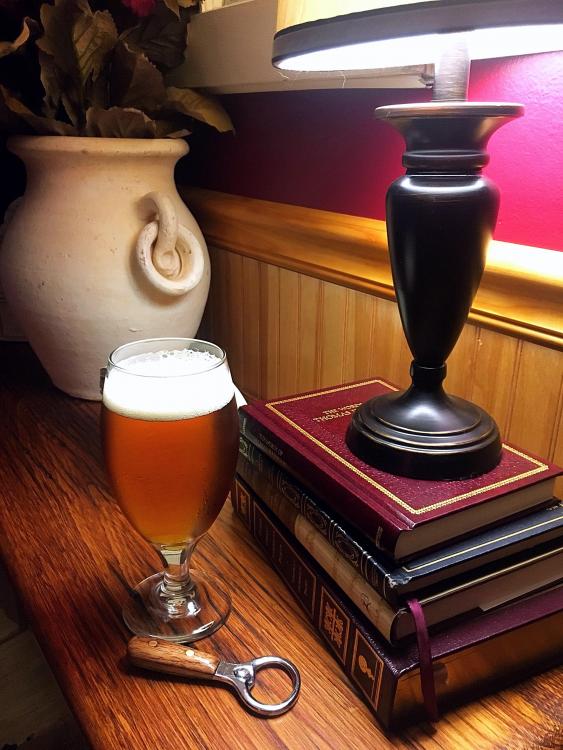

Made a mini opener. glad some folks here posted their wood handled openers. I’ve been having a blast making them. -

What did you do in the shop today?

GrumpyBiker replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Wine bottle corkscrew, what type of metal?

GrumpyBiker replied to GrumpyBiker's topic in Blacksmithing, General Discussion

Good tip. Makes perfect sense. -

Wine bottle corkscrew, what type of metal?

GrumpyBiker replied to GrumpyBiker's topic in Blacksmithing, General Discussion

I have no ego in this. I’m new to this hobby so I’ll gladly post my results. -

Wine bottle corkscrew, what type of metal?

GrumpyBiker replied to GrumpyBiker's topic in Blacksmithing, General Discussion

Guess I have no more excuse to not try one (or 10) . Our friends own a winery, I’d love to give them a couple to add to their silent charity auctions. My wife wants it for personal use ;-) -

Wine bottle corkscrew, what type of metal?

GrumpyBiker replied to GrumpyBiker's topic in Blacksmithing, General Discussion

I meant has anyone attempted one that is viewing THIS thread. -

Wine bottle corkscrew, what type of metal?

GrumpyBiker replied to GrumpyBiker's topic in Blacksmithing, General Discussion

Has anyone attempted one ? -

Wine bottle corkscrew, what type of metal?

GrumpyBiker replied to GrumpyBiker's topic in Blacksmithing, General Discussion

So leaf spring steel would be okay? If not I have a co-worker that says he has a coil from his old truck. -

My wife has been joking about the bottle openers , more specifically that I’ve yet to attempt a corkscrew. I am a little leary of attempting one this early in my metal moving journey but , why not? I’m at a loss for what metal would be best for strength and flexibility given how tough wine corks can be. If I’m able to actually pull it off I don’t want it to uncoil or break. So does any of the forum gurus know or have experience (successful experience preferred ;-) in making one of these and what type of steel ? on a side note, where would a person have the best chance of finding the appropriate metal “in the rough / wild” vs buying from a shop ?

-

What did you do in the shop today?

GrumpyBiker replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

GrumpyBiker replied to Mark Ling's topic in Blacksmithing, General Discussion

Nope just polished carbon steel -

What did you do in the shop today?

GrumpyBiker replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

GrumpyBiker replied to Mark Ling's topic in Blacksmithing, General Discussion

It was purchased at an auction for $8 missing the bale. She couldn’t pass it up. it was one of four cast iron pieces as well as these presses. -

What did you do in the shop today?

GrumpyBiker replied to Mark Ling's topic in Blacksmithing, General Discussion

-

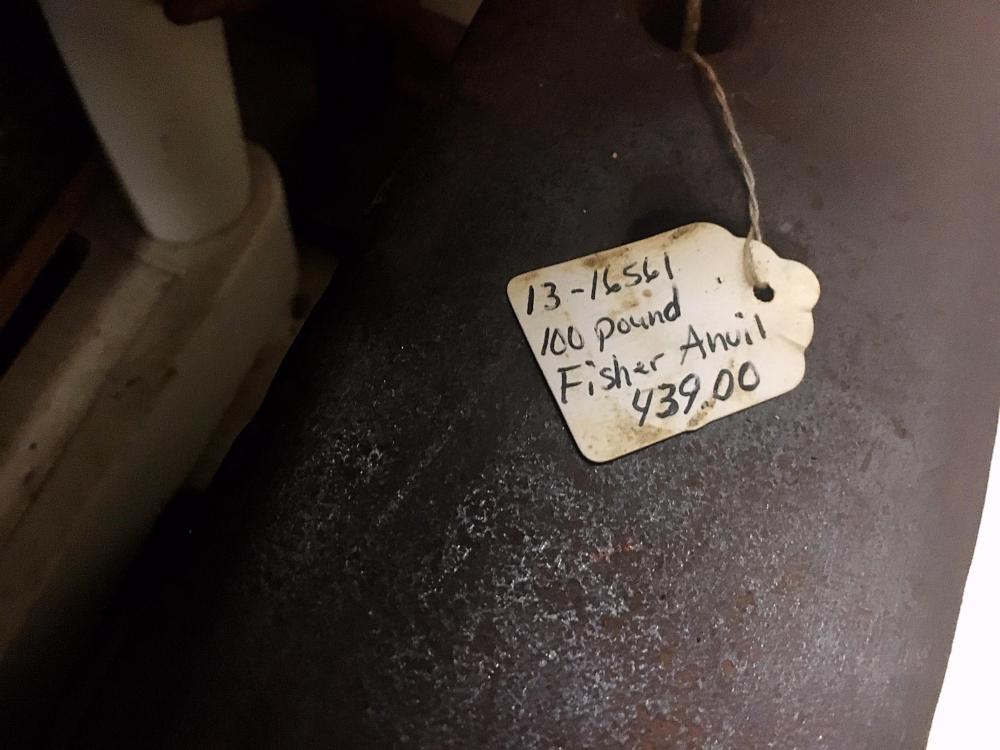

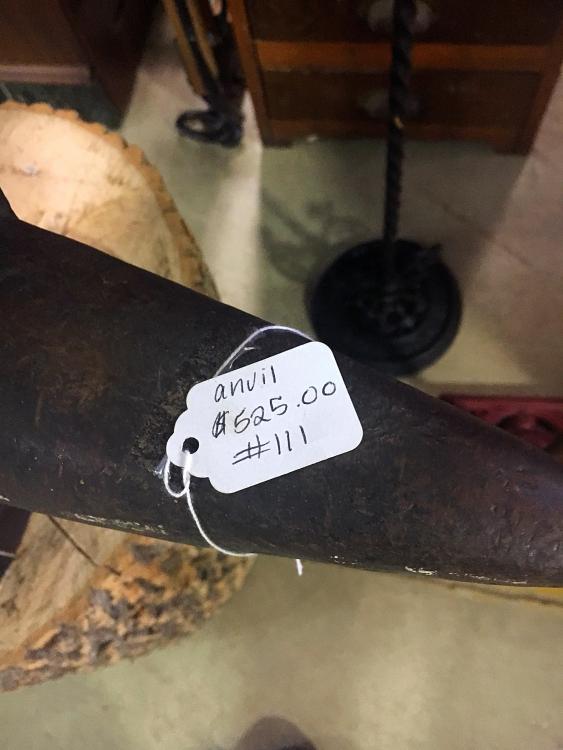

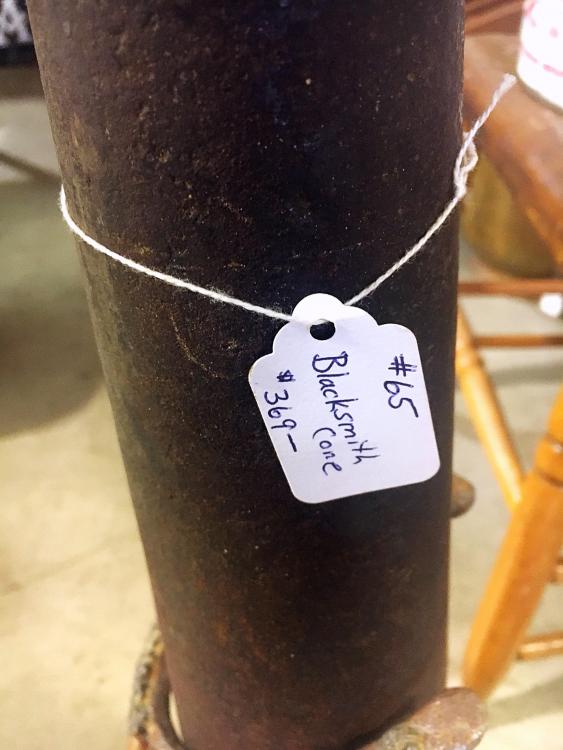

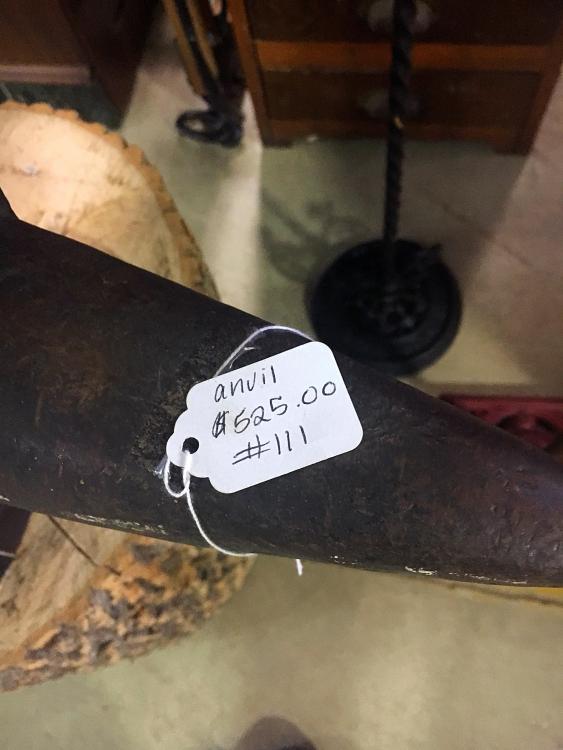

Daswulf, I hope the places I’m mentioning is not coming across as an Antique shop. Literally Junk-tique seems so much more appropriate. heres a shot of the guys booth I bought my anvil off of. When I go into an antique shop in Powel, Ohio it’s a bit different. But someone else has done the leg work so I expect to pay a bit more than if I discovered one myself. These just seemed like either junk or way over priced.

-

How were the prices on anvils at Wuad State ? I’d heard they were a bit high. I found another Junk-tique mall that had a couple anvils as well as the same vendor I bought mine from. He had a 100# Fisher with 1/2 the face plate gone for sale north of $400 ???? None of the markings were visible except on the Fisher. Am I missing something?! For my Blacksmith hunting area (eastern Ohio) is this normal? After seeing some of these I feel I got lucky.

-

A very modest one. Making a new bale for one of my wife’s cast iron Dutch ovens (on the assembly table).

-

-

I didn’t buy it as I just don’t have any use for it (I have a large post vise) but I did find it interesting and on the verge of sounding weird I thought it was “cute”. Someone put some time into making it maybe for a son or grandson. I was searching for hardy tools not a 5th vise. I just never saw one of these of this size and I won’t pretend to know much about Blacksmithing tools , so I am interested in whether these are common or just a one off thing. I could always call the shops owner & have them set it aside for me if someone is under the impression it has value other than as an item of curiosity.

-

Just saw this at the Junk-tuque store where I bought my anvil (two weeks ago) . Thought I’d share. Anyone else seen one of these ? Its 6” from the top of the jaw to the pivot box.

-

Anvil Stand Upsetting Block addition???

GrumpyBiker replied to GrumpyBiker's topic in Stands for Anvils, Swage Blocks, etc

That would be fine if I had a dirt floor or my shop was only used for Blacksmithing. Space is a premium in my wood shop so if I can have max use out of my work stations that's best . I'll not be doing work with large diameter stock. If it's not doable I'm interested in hearing your opinions as well. You guys have more experience with this work than I do but please understand I have plan or desire to Blacksmith as a primary hobby. Its just a supplement to my woodworking. -

Show me your anvil stands

GrumpyBiker replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Sealed it with linseed oil & it darkened up way more than I'd wanted or expected. But I'm sure once it has some slag on it it won't matter. -

Anvil Stand Upsetting Block addition???

GrumpyBiker replied to GrumpyBiker's topic in Stands for Anvils, Swage Blocks, etc

I was wondering if I could make a stake style upsetting block out of this 3"x3" piece of RR track by cutting off the flat bottom & shaping it into a stake. Then driving it into the Anvil base. Opinions ? -

What did you do in the shop today?

GrumpyBiker replied to Mark Ling's topic in Blacksmithing, General Discussion

Welded on my own bracket to the previous owners mounting bracket (or what was left of it. I'm no welder so it felt like there was as much grinding as there was welding !