Forgingforfun

Members-

Posts

82 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Forgingforfun

-

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

JLP Wally Yator is a awesome guy , glad you have one of his pieces, have known him for decades. He is a blacksmith dedicated to the craft. -

Time materials and hammer time

Forgingforfun replied to Forgingforfun's topic in Blacksmithing, General Discussion

Who's got the pop corn? I want to forge a railroad spike bottle opener, cut off point, fuller down forge out, punch, drift ,punch tab decorate with ballpien texture, time to forge slit, drive drifts punch tab spike.was free,3bucks a hour, that's what i need 0to make item My guess is one hour,3 ,3.5 lbs charcoal al -

Time materials and hammer time

Forgingforfun replied to Forgingforfun's topic in Blacksmithing, General Discussion

I'm game -

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you! So more of depression vs cutting I take? Thought may be braclet with curved ends, must take alot of patience, it looks professional! Do you draw pattern to depress /chase or just go to it? -

Time materials and hammer time

Forgingforfun replied to Forgingforfun's topic in Blacksmithing, General Discussion

Totally disagree with your response, it's that simple time vs material vs fuel to GET to a presentable presentation of work done wheres YOUR pics of work done??? How nice is it and how much time n material , fuel did it take to get to that level? You still love me? Why cant we all get along. Seriously I want the total answer of what u feel takes to get to a presentable level for your work, labor fuel and metal please.. -

Let's base this on all aspects, tapering , riveting, twisting, collaring, forge welding, etc... to get to a level where your work is presentable. Example....100 hours hammer time, 100 bucks in material, 300 bucks in fuel costs. I'm making a analogy to the fire triangle, heat, fuel and oxygen has to exist for fire. What's your thoughts??

-

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

Jhcc nice work , braclet? Show your tooling and share your angle of attack. Is that mild steel? -

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Still using charcoal, increased diameter of "bowl" , works well, used a propane torch while hand cranking , blower lights really good. My next and final test will be coal.

-

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Smaller pieces of charcoal make a huge difference. Yes indeed, area that is hot enough to do work is not big enough, I am going to increase that, and will switch to coal for a while, having about 150 lbs of smithing coal, I personally haven't forged with coal since the 70s in my dads forge, have used propane mostly, my bottom blast using pipe with holes didnt work well, but now I learned that my charcoal wasn't small enough in that attempt also. Good find on your charcoal.im getting very excited about my future projects.

-

Show me your Bottle Openers!

Forgingforfun replied to Arbalist's topic in Blacksmithing, General Discussion

Manage to forge out a couple bottle openers, not 100 percent sermetrical, but I tested them and they work just fine.. -

-

Yes I should of ...but would that have allowed the sweet spot to move taller in height? Airflow into is like 3/4 or inch. The bowl wasn't wide enough to fit tomahawk head into as well, have some more charcoal to use up then will switch to coal, still have to make a rake water can, poker etc

-

Need to improve couldn't get "fireball" tall enough, guess with sideblast I have to think horizontal not vertical, wasn't quite at welding temps, manage to partially weld a tomahawk.

-

Finally got around to hooking her up and lighting her off 20200425_084728.mp4 Another video, gonna try coal next 20200425_085111.mp4

-

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

Forged out a spatula today. Used sideblast forge with charcoal, also forge welded a tomahawk, but didnt weld 100 percent, really ugly not worthy of posting.lol -

Civil War era blacksmith wagon

Forgingforfun replied to Glenn's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

Forged railroad lantern hanger several weeks ago, forged the light house bird feeder hanger for the mrs today, she let me forge on Easter... question...I could only heat and bend the bird feeder once so I couldn't really transition the curve to a gentle radius. Due to size of forge, how could of I done so. Ps Happy Easter to all , and let's pray for this country. -

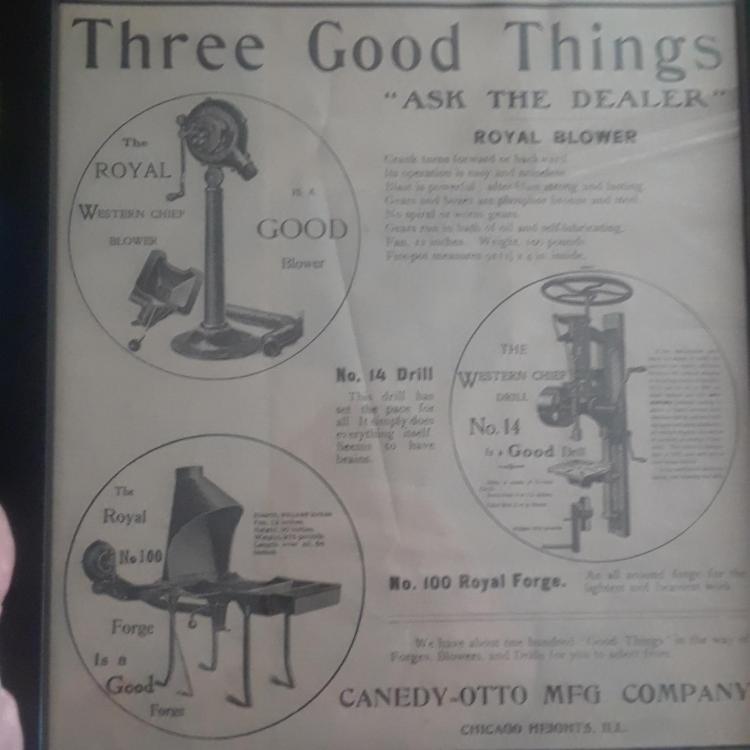

Built a table for forge, hooked up blower, will have to seal 3inch pipe to 2 inch pipe and am going to lag bolt base to 4x4 to bring level, may shorten stove pipe also. Framed a original Feb 1904 ad for same blower today also.

-

What did you do in the shop today?

Forgingforfun replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What temp for successful forge welds?

Forgingforfun replied to windancer's topic in Blacksmithing, General Discussion

Propane homebrew single venturi burner , small volume, I have only successfully forge welded san mai and 1/4 round with all the stars aligned several times, at a very bright yellow heat...hope to solve that problem when I go to using coke to forge with, no I dont want to modify gas forge to be more reliable to do the same. Coal to coke is in my future . Heat pressure in correct amounts, ....with lack of oxidation is the the key -

Thanks pnut have not made cut on side yet to allow horizontal pass for stock on side, not gonna use cutout on end, all I need to do now is build a stand for it

-

got some dirt packed in forge, want to fire up soon ..just to make some bottle openers, hooks, etc to make some coke...so I can cleanly make some forge welds on some tomahawks. My ultimate goal .

-

Yes, no user name that I can remember, but loved the simplistic use of knowledge and tools, that's were I got the wash tub idea from, I do have some charcoal that I may try with the sideblast setup. Btw I found out roofing centers have cheaper charcoal, they use in tarpots I'm told, cheaper than lumber outlets, aside making it yourself.