lyuv

Members-

Posts

198 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by lyuv

-

I"m curious about this "forced" curing. I find plenty of interesting green wood, and always passed it, because thought is was impractical to cure/dry it DIY. Can you elaborate on the method? Is it a known way?

-

I need to HT a D2 blade (2mm at the thickest) in a coal forge. I read that idealy, it needs to soak at 1020c for 1/2-1 hour. But It seems very hard to maintain steady temp for such a long time, and I assume carbon loss will be significant. How much "performance" (hardness? toughness?) do I lose, if I soak for only few minutes? What do you suggest?

-

Power grinders and presses are modern tools. But such ridges where commonly forged 2,000 years ago. Note that sometimes the ridges are tappered. If they used swages, this means the entire length of the ridge was formed in a single die (stroke?). Is this possible in that era's technology?

-

How would you go about forging a rib ("ridge"?) along the middle of a steel strip? Like on this Pugio dagger, or on a feather. There may be different techniques for a rib on one side and on both sides.

-

It seems common to consider vehicle's spring steel to be 5160. But when I checked with some manufacturers site's, they state a selection of other steels. Even if one of these is just a different coding system for 5160, they cant all be. My question is - would it be "safe" to assume a "mystery" vehicle spring is close enough to 5160, regarding it'a characteristics and heat treating?

-

Thanks. Thomas - your idea is good. However, I already spent a whole day going through most of the carpentry shops around, and could"nt get any band saw. Eventualy I found a tiny, dark antient shop, with an antient guy, who makes band saws manualy (!). He refused to sell me raw material. But in exchange for an hour of listening to stories of the old times, I received 2 meters. Sadly, It was only enough for 2 failed attempts. Anyway - I can get cars coil springs, per PNUT's advice - do you (or anyone) know if, welding to itself, it's a reasonable simulation?

-

I experienced several consecutive failures in forge welding knife billets. So I want to take a step back, and do some practice welds. The thing is, that other than blade steels (expensive and very hard to get here), I only have rebars. I know this material is generaly considered "bad" for blacksmithing. How will it do for forge welding?

-

When I was young, blacksmithing tools were considered junk, and were free. But nobody wanted them. Now these are sold as antiques for decoration, and priced acordingly. No bargains any more. Phats - Assuming you"re only starting, I suggest you limit yourself to the bare necessities. Anvil you already got. Buy cheap cross peen hammer at a hardware store. Perhaps a ball peen too. One per of tongs, and make some more. Quick-and-dirty will do. Make a chisel and your done.

-

Thinking of a powered TRIP hammer

lyuv replied to lyuv's topic in Power Hammers, Treadle Hammers, Olivers

Thank guys. I"m not sure I used the right term. I mean something like this: It's a good point about power control. So I thought to add a spring that pulls down on the hammer (like in the picture), and a pedal that controls the tention of that spring. So I can increase the striking force with that pedal. However, I d not see anyone doing that, so there may be a bug in my logic. -

Spring loaded hand hammer

lyuv replied to larrynjr's topic in Power Hammers, Treadle Hammers, Olivers

If your goal is to ease the load on your arm, you need to gain some advantage. Mechanical, energetic or ergonomic. And I see none. You need to move the same mass and your arm provides all the energy. The differance is the path, that seems less natural - further from the body, and arched away. Another differance - more force downward and less upward. I have no idea if this is better or worst. I think you can gain advantage by increasing the swing length. Hence, less force/strain (but for a longer time). The device will also enable you to "hammer" with your weak hand. Another point - Any moving mass that is not the hammer itself (the angle iron, the arm ect) , is wasting your energy. You need to accelerate it, and gain very little of it's momentum into the forging itself. Do try to minimize that excess mass and/or it's distance from the pivot point. -

I need (want?) a power hammer, and intend to build one. All I could get for it is a 3/4hp motor. My dilema is the configuration: Most power hammers I see, use toggle connection between the hammer and the motor.But a trip mechanism is much simpler and suited to my humble means. Why is the trip hammer so unpopular? Will I be loosing much if I"ll go this way? Is there a simple design that is significantly better?

-

Pricing my work makes me uneasy

lyuv replied to jwilson645's topic in The Business Side of Blacksmithing

I asume the problem is COMITING you and the client to the deal. Perhaps there are ways around that comitment. Like: 1. If the grate may fit other clients, you can make it first (or several), and then price it. Let the client decide if he wants it. 2. Make part of it, so you get better estimation of the work ahead. Then price it and see if the client agrees. Worst case - you lost some work. Perhaps it's reusable. -

As for kitchen utensils. and specificly knives - over use and time (few weeks), the metal will get a layer of "patina" - sort of oxidation that will protect it from the "bad oxidation" - red rust. At first it looks like dark and unsightly spots. Dont rub them off. Wash the knife gently and oil between uses. the darkness will grow (hehe...) and you"ll get a protective layer, so you dont need the oil any more.

-

Some AWSOME dragons where presented on the forum, so I wanted to try my hands at one (in other words - got jealous...). In addition, the wife asked for a buissiness cards holder. So the plan was a fierce dragon, with a long sneak like body, coiled to form a cavity for the cards. Never made dragon scales, so I made a scrap test piece. Then made the head (also a first). When a kid thought it was a donkey, I realized change of plan was in order. The test piece was recovered, welded to the head, and a more "lay back" dragon emerged. It does hold cards - on it's feet, against it's calves. However, the wife sais "it's too nice to take to the office". Whatever that means...

-

Several days ago I mentioned I know Hofi, and was asked to post about his well being. Several months ago one of his legs was amputated, followed by a long hospitalization and rehabilitation. But it's only one leg, and Hofi is only 84 years young. So no biggie and he's back at the anvil. I visited him today, and disturbed him grinding a batch of several dozens hammers. He also plans to renew the classes. BTW - in November he will host a celebration for the 30th anneversary of the smithy (and smiithing). There will be a large log, and each guest is invited to bring a nail he forged, and stick it in the log.

-

Countemeasure, correct me if I"m wrong, but seems you have not hit hot iron once. That's perfectly fine, and looking for your first hammer is a good starting point. But planing advanced projects, and striking station, is jumping WAAAY ahead. I have been there not long ago (and I"m not far from it now). Blacksmithing is NOT what it seems before you start. For example, hot steel is much harder than it seems on youtube. There are lots of limitations you need to account for when planning the steps for every little project, ect. I suggest you first get some experience. even few hours, before you procceed planing.

-

At least here, this type is known a "German hammer". So perhaps in Germany it's knows as a "Hammer". [commercial link removed] I think you"ll find it in any hardware shop, and for only few euros. no need to order from abroad. As to making you"re own - nice, but it may take a long time to get there. NOT a beginer's project.

-

Too small is not as bad as too big. As we dont know your physical build and capacity, 800gr is generaly OK. But I reccomend that you also get a 1-1.1kg cross peen hammer. At least a cheap one to start with. There is a good chance the 800gr will get too small after you gain some experience. My blacksmithing teacher claimed normaly you should start with the final hammer, which is 1.3kg (or 1.1 for women).

-

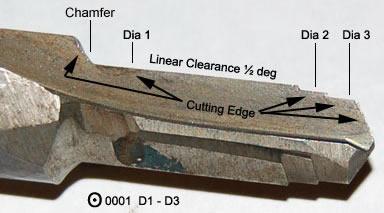

Not all reamers are straight or plain tappers. Here is an example of a speciality reamer. Mine also has a radius thrown in...

-

Two parts answer, and it too is serious: 1. Those of us that blacksmith for a hobby, could also find a more productive use for their time and money. But the chalange and the joy of making, are my (our?) reward. Same with the chalange of making a reamer. 2. The reamer is of special shape and not available. But it is needed for a project that is "only" for fun. So back to 1.

-

Thanks all. Laticinno - that book is AMAZING! G-son - First, I have never done this, so my plan is no more than hope. That said, the plan is to turn the reamer on a lathe to the general shape. Cut longitudonal grooves (with a Dremel), leaving several "blades". File the top of those blades at a slight relief angle, except for a narrow strip at the cutting edge. and finaly harden and sharpen with a stone.

-

I need to make a metal cutting tool (a reamer). So it needs to be as hard as it can be. The question is: should I temper it after quenching? The steels I have for the reamer are O1 and 5160. It's for a one time job, and needs to cut annealed steel. Thanks,

-

WHAAAAT???? Why did nobody tell me about this before? I have been struggling with crumbling steel (mainly O1) since I started blacsmithing, and especialy bladesmithing. I blamed working too cold (...). I blamed air blasting through the coal. Blamed the hammer Seriously. That piece of information about hot shortness, is of top importance to any blacksmith working with steel. HUGE thank you to JHCC, Thomas and Irondragon. To anyone who tutors novice blacksmiths - don't forget to teach this!

-

It may be my English, but I"m not sure what you guys mean when you say you got "cottage cheese". Do you mean burnt steel, or fractured? If it's "fractured" - I"m confused. I assumed that as steel gets hotter, it gets softer and more malleable. Hence, less prone to crack under hammering. I always "knew" that hotter = easier to work (up to the burning point, and beside the grain size issue). Is that true only for low carbon, or low alloy?

-

Tried to forge weld two 1/2" bars. Hammering it, at what I thought was welding temp, the steel started to crack and crumble. How is that possible? Some info: 1. I"m a lousy welder, and poor judge of temp. 2. It's possible I got to burning. The lump on the bottom is a piece that broke off the end of the bar(s), and it looks burnt. BUT - the rest of the bar is just cracked, and that's the issue. It kept fracturing and falling apart. 3. The steel is a car's coil spring. Can it be some sort of steel that cant handle the heat? (at least in a blacksmith shop conditions)