Eli Taylor

-

Posts

33 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Eli Taylor

-

-

On 7/5/2017 at 4:24 PM, littleblacksmith said:

Know I'm late to this conversation, but that looks an awful lot like a looooong pipe wrench sans the top jaw and frame.

-

This is great, I have dreams of machining my own castings or forgings at some point, like you I like the whole process as much as the destination.

Great problem solving and man I really want a mag drill

there's been one on cl locally for 6 months now but I just can't drop $500 on a single tool right now.

there's been one on cl locally for 6 months now but I just can't drop $500 on a single tool right now.

Keep learning and sharing!

-

-

-

-

1 hour ago, ThomasPowers said:

Volume = Volume (subject to scale losses ...)

18 minutes ago, JME1149 said:and as mentioned above, factor for scale loss

14 minutes ago, JHCC said:Add in scale loss, and you're looking at a finished piece that's even smaller.

Would I be wrong in assuming that you cannot really estimate a scale loss % (by volume) due to the fact that it depends (in no small part) on the number of heats?

-

$8,000 will currently net you a 990lb German Anvil

-

7 minutes ago, SLAG said:

Another good choice would be to use a D-amino acid. (most functional proteins use L-amino acids as constituents.)

Interesting, I never knew a difference. I wont claim to understand all you wrote, however it now makes sense why I see L-Lysine on the bottles.

7 minutes ago, SLAG said:the movie military used the wrong weaponry to attack the dinosaurs. Bullets would do little harm. But a shaped charged recoiless rocket will do the job handily.

LOL I can think of a lot of movies that would have ended a lot quicker if the defending force had access to Shaped Charge Recoil-less Rockets!

Who knew what kind of expertise was lurking on the smithing forums

Now off to lookup Great Bellows plans for my and my son to build!

-

3 hours ago, Frosty said:

If a person would like to worry about modern science and things coming down the pike, consider self replicating nanotech

Ah yes, the "Grey Goo" scenario!

2 hours ago, SLAG said:They can also be modified so that they cannot survive without a specific uncommon biochemical

Seems to me Michael Chrichton addressed this in Jurassic Park with the Lysine Contingency. The end of the novel has the escaped raptors seeking out plants that are rich in naturally occurring Lysine

I cant bring myself to quote Jeff Goldblum...but you know the phrase

-

15 hours ago, SLAG said:

the probable next moves to isolate the plastic digesting gene. And eventually placing copies of that gene into more convenient organisms than the wax worm. (bacteria or fungi etc.)

This is how most Sci-Fi horror films start...

Innocent solution to a problem, not fully thought through.

Bacteria with plastic eater gene gets released into the wild, and within months all plastics/polymers are in a state of heavy decomposition. All electronics as we know them are now inoperable...a side effect is that the Blacksmith is now back in demand as we've regressed 150 years

-

54 minutes ago, ThomasPowers said:

it would be real nice to have a roofed over but open walled "carport" off one end of the shop...

aka "cold storage"

-

4 hours ago, ausfire said:

Eli, what are those pointed things in the bottom centre of your second pic?

53 minutes ago, Farmall said:Those are cape chisels.

Yeah, I actually didn't know what they were called either, just knew they were slim chisels

21 hours ago, ThomasPowers said:

21 hours ago, ThomasPowers said:So how's the shop expansion coming along?

Expanding is dangerous, that just means more empty space that will be filled at some point!

-

These are great and simple (hand-in-hand), good idea!

I might also wrap a portion of the bending mandrel with some sandpaper to give the insides a quick polish (since its a bright finish)

Definitely stealing the idea

-

-

A local machine shop was having "the scrap guy" come to pick up some older equipment, I hate seeing good tools go to the scrap yard so I picked up 6 of these monster 3 Phase Delta drill presses at scrap price.

Yesterday my son and I went to a local scrap yard (we are lucky to have 3 within 20 minutes of us). This one is a U-Pick yard with vehicles, so we scoped out some old tow trucks for their rigging equipment. We picked up a goodly number of D-Rings (2 Ton) and some hooks (one swiveling)

We also found 2 good lengths of chain with hooks on them, one has a swiveling chain (was from an old winch)

We had our eye on some chain with 4" long links, but the scrap guy stopped us and said they were for their use....I'm supposed to call him back this week and see if hes willing to part with it at scrap price : )

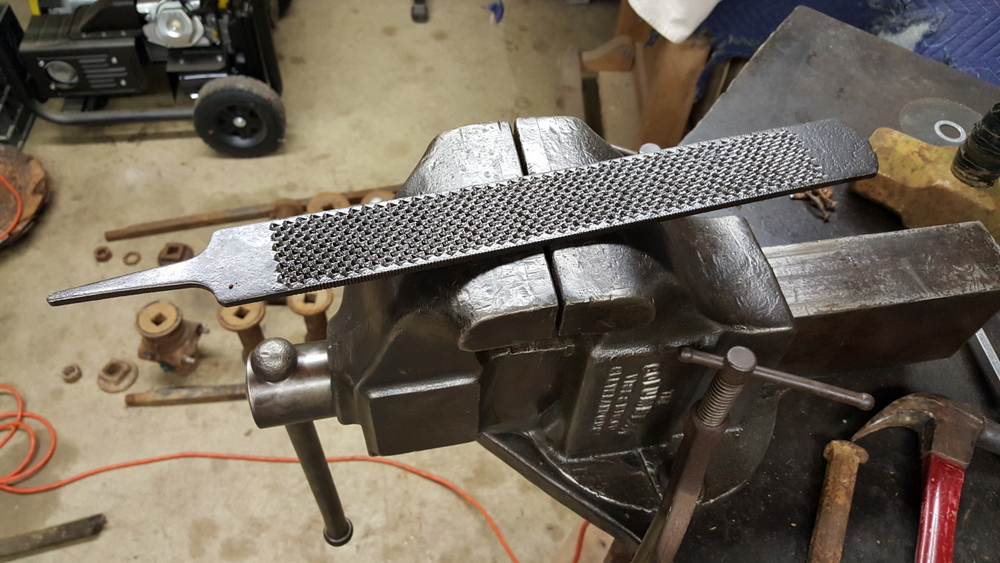

Then my son spotted a file in the dirt which turned out to be a farriers rasp...it cleaned up nicely and is plenty sharp

Then he found an 8" C Clamp right next to it buried in the dirt

Then he proceeded to find 35 more Farriers Rasps in the same pile!

And as if this wasnt good enough, someone had dropped off a 5' Disc Harrow on top of the steel pile which we've been wanting for a long time now

It needs new bearings on one gang and some weld up on the two front axels, but that makes good practice in casting and welding

I finished the day with cleaning up and reassembling the old vice I picked up last saturday in my barn pick

A very satisfying day overall

-

36 minutes ago, JHCC said:

Are you familiar with the "informational interview"? It's not a job interview, but one where you call up a company or an individual and say, "I'm thinking about switching careers to welding. Could you spare me half an hour of your time for an informational interview, for me to learn more about the field/your company/your experience/etc?"

I've had good luck with this several times by walking in and just saying exactly what you are up to.

I've been on several very cool 'shop tours' via this method (one a fabrication shop).

-

2 hours ago, Ken G said:

Couldn't pass up a bunch of 1"x1" stock

Thats great, do you know what it is (wrought, steel etc)?

-

1 hour ago, Tubalcain2 said:

shoot ,Eli,that is a stinkin nice drill.

1 hour ago, littleblacksmith said:ooooohhhhh I like that drill!!

1 hour ago, Frosty said:That is one sweet drill

Yeah, i was really lucky to have the seller sell me that for $300 and for watching his Chicken/Goose/Goat while away for a week

He also gave me a Van Norman #12 Vertical/Horizontal milling machine as my "commission" for helping him sell some equipment!

And if you like that drill, you might like some of the pics from where I volunteer from time to time (a line-shaft machine shop)

-

2 minutes ago, Tubalcain2 said:

I have one and I never use it. faster and easier to use a power drill.

Ok, that was my suspicion, thanks for the reply.

I'll probably pick one up at some point so we can have a traditional setup for travel and shows etc.

However in the meantime, I've got one of these which should do the trick

-

I know for some things like a Post Vice say, there are some specific attributes that make it a good choice for smithing over modern variants.

Are there similar attributes for a Post Drill that better suit them to smithing or were they just the predecessors to modern drill presses?

I have several modern drill presses already however a Post Drill is listed locally, wondering if there is some merit in it other than the nostalgia.

-

2 hours ago, Frosty said:

The guy holding the drill is called the shaker, once you're very deep you have to give the drill a shake before it'll turn. The guy on the sledgehammer is called the Steel Driver. John Henry was a steel driving man

One of my favorite bands Blue Highway has a song 'Born with a hammer in my hand ' with both of these references in it, i was just listening to this the other day

John Henry was a steel-drivin' man

You could hear his hammer ring across the land

But before the steam drill came, John Henry knew my name

Cause I was born with a hammer in my hand

The bossman tries to break a good man's back

It takes thirty men to lay eight miles of track

If the shaker holds the line, they'll be thirty miles behind

I was born with a hammer in my hand

-

3 hours ago, Lionel h said:

What kind of vise you got there , looks just like one I've got.

It's a Champion, 5" jaws, with a real wide mouth (18" in I'd say). There are some marks on the inside of the casting but I haven't looked up a model # yet.

1 hour ago, SmoothBore said:the "star punches" aren't punches at all, ... they're "star drills".

Ive actually never really known what they were (have a bunch from various sources over the years).

How are they used? For metal?

22 minutes ago, SLAG said:Speaking of log tongs, the device resembles tongs for handling ice blocks.

There were three types of tongs there best we could tell for Hay Bales, Ice Blocks and Log Skidding.

The Hay ones were wider and thinner, the ice tongs had their bite perpendicular to the tong and these which we assessed for logs have a very aggressive bite back in again themselves.

We could be wrong on all accounts but it was our limited archaeology

-

Like a moth to flame I'm drawn to old barns with piles of old over-built tools rusting in the corner, and so it is that i came home with a pile to put in the corner of my barn!

A nice champion vice

A very cool hand forged log skidder

I love how the links were bent around and peened

A bucket of mostly star punches with some drifts and rr spikes

A big pair of bolt cutters, 36" and 48" pipe wrenches, some axle stock, and a couple of misc hammer heads

And honestly I'm not sure why I have this but I couldn't turn down what appears to be a 10 Ton chain hoist (which we had to lift with the 1 Ton chain hoist)

I also picked up a couple 3 jaw pullers, some manure forks and 40' of heavy chain.

All in all a good days haul

And I forgot to mention; a 100lb anvil!

-

Went picking today in the barn of a local farmer who is selling his property. This is the same guy I bought the wrought iron fence from last week.

The anvil is 100lbs and definitely smaller than we're looking for long term, but it was available, has a good face and was a reasonable price.

We hit it with a twisted wire cup to clean the crud (we'll add or own crud thank you

and to see if there were any markings

and to see if there were any markings

The only I could see were on the bottom 1 1 1 8 which indicated to me that it likely has a cast iron base (as the letters are raised)

I soaked it up real well in 3in1 Oil (my go to) and will let it drink up as much as it can before rubbing it in again and wiping it down.

It was interesting to see that the table and top of the horn both appear to have a hard face as well...i somehow didn't know they did this on anvils

I scored some other cool stuff as well but I make a different thread for that.

I welcome any info anyone might have on this little guy.

Repairing Anvils - An editorial from 1897

in Repairing and Modification to Anvils

Posted

I came across the following editorial article in "The Blacksmith & Wheelwright" (Volume 37 No. 1 Jan 1898). I know the topic gets some airplay now-a-days and liked how the skeptical reply of Mr. Schmidt echoes the wisdom we still hear today. Thought I'd share:

Several years worth of this periodical exist online and it is often an interesting read. Additionally the many ads (just as bad as trade journals are today : ) are great to look at and imagine what it would have been like to have access to such a plethora of tools from many vendors.