-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by MBForge

-

Hi Frosty, Well, thanks for the reassurance and words of encouragement. If what you say is true, and I'm sure it is (seeing as I can't seem to find high temp paint rated for 2,000 F, *tongue in cheek*), I do find it a bit misleading why someone would make it look pretty when it's just going to burn off anyways. It gives the impression that something's not quite right when it has the "appearance" of deteriorating so quickly. At any rate, I'm not big into appearances myself and can get on board with everything you said. As such, I feel better moving forward with the plans I have to burn off even more paint tomorrow Thanks for the sanity check!

-

Following this advice the other day, I did crack the door open for the first few heats only to find the paint in the surrounding areas in the front were being consumed away as well around the sides, top, and the door handle, all of which I'm really not too happy about. The only "relief" for the forge's exterior paint I could find was in leaving the front door wide open, which I presume didn't make for very efficient forging. (Please see attached photos) I'm going to be sending these pictures to the manufacturer as well for their opinion, but I would really love to know very simply at this point: is this sort of wear normal for commercial gas forges like this? Just a bit disheartening seeing this kind of exterior wear on a very expensive gas forge that was just given to me brand new and I feel really bad that it looks like this after two sessions. Appreciate your input. Thanks!

-

Common Basic Mistakes That Beginners Should Avoid

MBForge replied to JHCC's topic in Blacksmithing, General Discussion

Mistake #16b (or #18b) - For those doing 2-4 fire brick forges, myself included: attempting to handle HOT fire bricks which don't show their color either (i.e. picking one up that got knocked onto the ground, but with your bare hands). Trust me...I know. -

Been digging around in that thread for a little while and some other threads on kiln wash. Just to be clear, if I can fork over the $100 for some zirconia-containing wash (ITC-100), it would be worth the investment in preventative maintenance? Also, are we talking about coating the entire thing, or just the floor? And how much? The liner in this thing is hearth pad/brick, except for the door: that's some kind of insulation blanket. Hoping to fire up the forge again soon, but can't recall being able to get the stock I was using up to a yellow heat; mostly bright orange. I may try increasing the PSI next time (12 PSI was factory recommended default for starting out) but am wondering if the kiln wash may also yield any insulation/re-radiating benefits to contribute to this as well.

-

"Root" as in occupying that space myself or the metal I'm working? I do have a Bernzomatic TS8000 I plan to heat my small anvil surface area with and can probably keep a heated railroad spike in an adjacent hole near the top. The area itself is pretty open, I don't plan on hanging out near the forge to stay warm as it's nearby my indoor workroom with a heater in it I can duck into. The blower is a B-Air VP-20 that will be set up near where I work to draw stagnant air in and push it away from the work area. It shouldn't affect the heat in the forge. Good to know. Also, I have a 40lb. tank so hopefully it won't freeze up too quickly either. Thanks guys for your input. Always appreciated!

-

Winter is coming. Any concerns using the propane gas forge outdoors in 30°F weather? Have an air mover I'm considering setting up for additional circulation since the last time it seemed there were caramel-like odors that seemed to just linger in the air.

-

Ended up passing on the anvil due to time constraint. We were only passing through the area during a short stay in California.

-

I guess the main concern I'd have with it is watching the horn break off after a few taps if those cracks might be any indication...

-

Thanks. Any concerns with the horn? I do notice chipping underneath there.

-

-

Sorry, not sure if this is the right place to post this, but any thoughts before I start putting serious thought towards making this [100# anvil] my own? [Commercial link removed] Would be happy to update this post with actual pictures if I do get it.

-

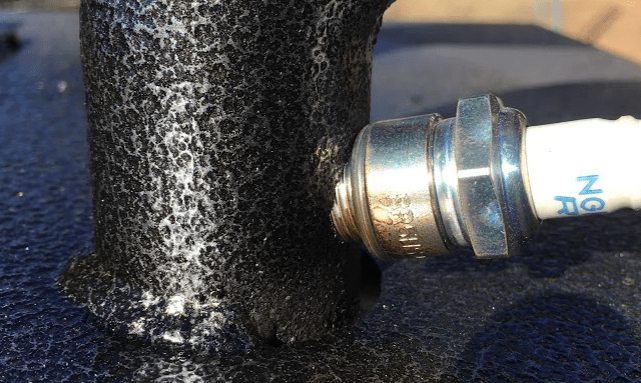

From the company: "From the pictures I would guess that your flame was also burning inside of your tube, causing it to burn off. You need to make sure that on start up you open the valve a good 2 times at igniting. This makes sure the gas is blowing through the burner verses burning inside of it." Guess I'll try that as well.

-

Adding to my winter project list: rail system for hauling 85 lb. forge up a set of stairs.

-

Respirator recommendations for operating gas forge?

MBForge replied to MBForge's topic in Personal Protection Equipment

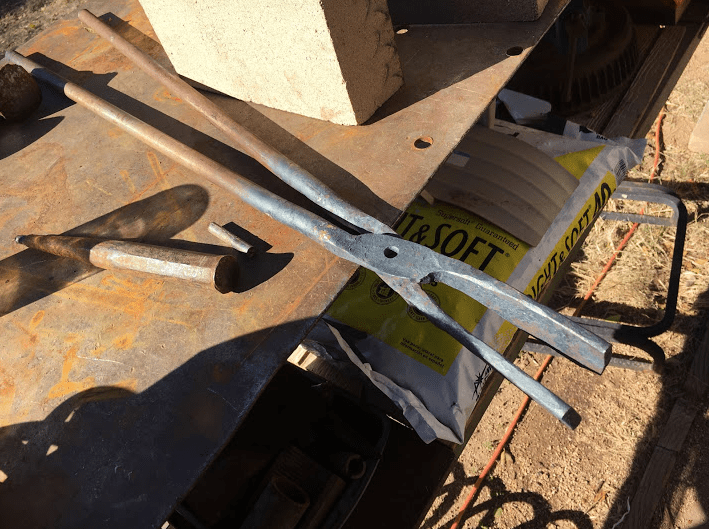

Now just to reiterate, I was forging outdoors and have no intentions of ever forging indoors, "nor do I think I'd want to if I had [a workshop]." I'm about 70% convinced it might be mild metal fume fever, but perhaps someone can help confirm. These two rods I was forging yesterday are from the same stock. It was a longer piece that I picked up at a garage sale that appears to have been a water shutoff rod (curb key, etc.), albeit a rather tall one. I sanded a section here a little bit. Can anyone identify what the coating here looks like (if not rust)? Particularly the bottom of the two that has sort of a bronze tint almost. Great points! Yeah, I'm about there myself. Have plenty of files given to me to build tools, knives, etc. with as well as an indoor workbench project for the winter months ahead. Thanks for the encouragement! Just need to come up with a list of small item projects now -

I don't have a workshop to put a forge in, nor do I think I'd want to if I had one. [I shall see how long I can weather this winter when I don't get to forge like all the rest of you Torbjörn Åhmans.] Anyways, I have a respirator that was given to me (AOSafety mask with R53HE-P100 cartridges) but some research shows this company has been absorbed into 3M and cartridges are no longer available, except for a premium on Amazon, eBay, etc. Any idea on how long these things last? The only possible marking remotely resembling any kind of expiration date is a stamp with the following numbers in green: 102403 (good through Oct. 24, '03???) I'm currently looking at this Miller LPR-100 said to filter 99.7% of welding fumes and mists. I also do some MIG welding and am hoping it will fit under my welding helmet. I was wondering if something like the Miller LPR-100 would be appropriate while operating my gas forge outdoors in regards to CO2, metal fumes, etc. or if something else would be better. I realize it may be less of a concern for some operating a gas forge outdoors. However, yesterday's sudden onset of stomach aches seemed to coincide with taking off my current mask outdoors after forging, and the open air which smelled like burnt caramel. Or it might have been purely coincidental with a stomach bug going around right now. Either way, I feel like I need to get a proper fume respirator for ongoing work. Appreciate all your input. Thanks!

-

Absolutely! Except for one small detail: stairs.

-

Thanks, and yes, I will certainly make it a point to update this thread with my results. I've also emailed the company to see what they say. Trying to be careful with this forge because the replacement lining kit itself runs around $140. By the way, the thing weighs some 85 lb. and is a bit much for me to be carrying in and out of my storage area (don't have a workshop, unfortunately). I do have a rain-resistant canvas tarp to help keep frost off of it (as in last night), but wonder if that will sufficiently protect it from the elements if I wanted to just leave it outside.

-

I wondered about that and perhaps hoped the excess heat would have sufficient escaped out the side holes. I will certainly try that next time (maybe tomorrow). Any tips on possibly restoring the paint (what kind of paint is this, anyways)?

-

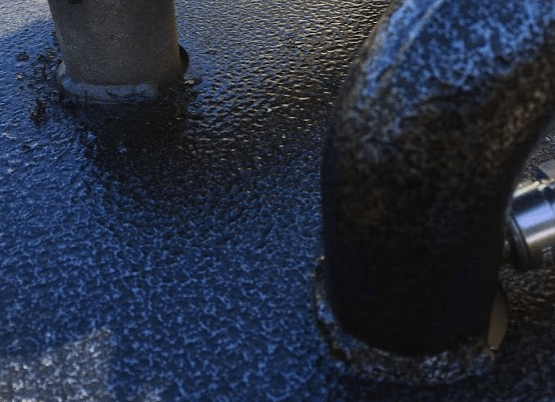

Fired up the gas forge yesterday and had a blast! Lot more fun (and efficient, fire management-wise) than I anticipated. The first pair of tongs I ever made was months ago out of rebar after watching a YouTube video. Didn't quite come out right and not suitable for what I needed. This pair is almost done and coming along much better: I do have some concerns, however, about some heat escape out the top. There seem to be these gaps in the top where the burners are welded to: ...the paint got burned off the left side: ...and also started to burn the spark plug on the right side: I kept it about 12 PSI and kept the front door closed the entire time, per the operating instructions. Am I missing something here, or is this normal?

-

Hi all, Had a rather unexpected gift "on its way" given to me for my birthday this year: a dual valve Forgemaster (Blacksmith model). I am not a farrier by trade or professional by any means; this has strictly been a hobby to date so you can imagine how completely floored I was. Well, It's been sitting on my desk assembled for over a month now, still brand new. Quite frankly, it just feels too "rich" (or nice) that I almost don't want to fire it up. I'm forcing myself to take it out this weekend Anyways, I've already read through the article Can Your Forge Take The Heat several times as I really don't want to mess things up, this being my very first gas forge and all. I'm a little concerned about the outside deteriorating as shown in the header image of that article: is that normal? Besides the standard operating procedures and the precautions outlined in this article, is there anything else I should be aware of? Also, if someone has this same forge, I would especially appreciate a brief how-to video demonstrating proper operation and forging with it. Thanks! Additional resources (mostly reference list for myself): What do you wish you knew before using a Gas Forge?

-

Thanks for this info. This is pretty much what I needed to know. I did also part it out for the foot pedal which is why the thrift shop gave me whole unit for $5. I might toss the unit (with motor; no foot pedal) on Craigslist for a week to see if I can get anything for it before tossing it out completely (unless someone else here wants it).

-

Attached are some photos of the parts I'm thinking about salvaging from a vintage Morse Super Dial sewing machine I picked up at a local thrift store for $5 Info: http://stagecoachroadsewing.com/msd.html You'll notice the parts are made by Toyota. Curious to know if anyone knows if these kinds of parts might have toxic elements in them (i.e. chromium, cadmium; they're obviously not galvanized, etc...) dangerous for forging. Thinking about using them to make some punches, perhaps a knife, etc. if they're any good. Thanks!

-

Can I use this for an anvil (unidentified)?

MBForge replied to MBForge's topic in Anvils, Swage Blocks, and Mandrels

Or stackable weights? http://www.freedom360.eu/shop/stackable-weight-pack-of-3/ Holes may plausibly be lightening holes as well as the large one is precisely 62 lb while the small one is 12 lb: https://en.wikipedia.org/wiki/Lightening_holes -

Can I use this for an anvil (unidentified)?

MBForge replied to MBForge's topic in Anvils, Swage Blocks, and Mandrels

Well, I went ahead and bought both of these, thanks to ThomasPowers for putting dropping the bug about the horn idea. Between that and the Pritchel hole idea and valuation by JHCC, I'm pretty content with what I landed. I'm just calling these "steel columns" (or possibly counterweights) at this point. I haggled a little bit and picked up both of these for $30 out the door: 62 lb. round steel column (2'1" x 3-1/4") for sheer mass behind anvil face 12 lb. round steel column (6-1/2" x 3") for horn Comes out to about $0.40-0.41 per pound Got some holes to drill in some other stuff I found at the junkyard as well for my brake drum forge and hope to be able to do a little forging this weekend. I think half the adventure is in hunting these parts for cheap, and I hope to remember the prices I paid for everything, but I think I'm ready to assemble it all together at this point and start forging (it's been a long wait). However, I am slightly considered about the seams in this smaller one. Haven't seen if there are seams in the larger one yet. Are these going to be an issue (i.e. delamination)? -

Can I use this for an anvil (unidentified)?

MBForge replied to MBForge's topic in Anvils, Swage Blocks, and Mandrels

Hence my thought to lop off that first hole as there is more mass below it. But I guess I could wait until it does start to sway I've made several attempts to secure a decent anvil, but what I have just isn't working (broken railroad track, flat plates, etc.) Your recommendation on mounting it is exactly what I planned to do (after watching this video): https://www.youtube.com/watch?v=4EY1uvc6igw&t=2s. But the custom "pritchell" hole idea as you've shown here is something I didn't even consider, so thanks for that! Just had a question on this part though: "Ease the sharp edges of the bevel..." of what though? This steel column to be used as an anvil or the tool you have pictured?