-

Posts

65 -

Joined

-

Last visited

-

New (to me) Coal Forge

TastefullyPeenedIronWorks replied to TastefullyPeenedIronWorks's topic in Solid Fuel Forges

All you guys crack me up, I’m dying here. Definitely need the steel rests level and in line, I agree. My wife barely steps into the forge, she’s super cool about it, I’m so darn lucky. I honestly wasn’t sure if fire clay acted as a sacrificial barrier much like kaowool and refractory when welding and using borax. I think I understand more… Stupid is as stupid does, lol -

New (to me) Coal Forge

TastefullyPeenedIronWorks replied to TastefullyPeenedIronWorks's topic in Solid Fuel Forges

I want to move this thing inside, as long as my wife doesn’t mind another whole in the garage lol -

New (to me) Coal Forge

TastefullyPeenedIronWorks replied to TastefullyPeenedIronWorks's topic in Solid Fuel Forges

Twistedwillow, I will pm you soon with some dimensions and we can discuss further. frosty, thank you! I just got up from a night shift and this is all very good information. I don’t intend on doing it in the next week or two, I plan on really laying this all out before tackling it, so much of this is new and unfamiliar water for me. That being said, I do have very minor experience with coal. I have a lot of reading to do and than it’s all hands on. I do intend on doing “larger” stock but that is a relative term. I would like to get into some hammer making and ultimately, would like to start doing grills, grates, doorways, railings. I want it all! I wanna learn it all!!! Fire and Metal and hitting things with hammers! Lol what is the work life of a clayed forge pan, usually? 3-5 years before relining? I’m just taking a guess, I really don’t have any clue. -

These are all such good and diverse responses. I can honestly see the point each one of you is making. To be entirely fair, it really sounds as though the decision to refine the work to a point in which it bears no manufacturing marks is at both the discretion of the craftsman/woman and the client. I don’t consider leaving unintentional hammer marks on a piece a witness mark so much as sloppy/lazy workmanship.

-

New (to me) Coal Forge

TastefullyPeenedIronWorks replied to TastefullyPeenedIronWorks's topic in Solid Fuel Forges

Daswulf, Never heard of the stuff but I am positive, just by the name, I’ll be solid with that, I have Zero intention of painting the inside of the pot but I’m thinking a good coat of that stuff on the underside now and again wouldn’t hurt any…Any time you are in Bucks County, PA you have a cold beer and some hot iron waiting. The First 2 pictures are the broken blower, the second 2 are what I intend to replace it with. I’ll need to find an adjustable speed 1hp motor to run the blower but, everything in its time and place, no use getting too far ahead of myself. I can’t imagine running this monster on a hand crank, no thank you. As a note, the pipe diameter on the broken Lancaster is 3inch. The Sanderson is 3.5inch. I am wondering if at least lining the firepot with satanite is wise for overall longevity -

New (to me) Coal Forge

TastefullyPeenedIronWorks replied to TastefullyPeenedIronWorks's topic in Solid Fuel Forges

George! Thank you for the siege advice. I don’t know if it’s quite ready to just start running but it is darn close. I agree, perhaps, once the rust is off the bed, refractory mixed and poured would add a good layer of both heat resistance and durability. The hood definitely had a few minor holes/cracks that I’m sure smoke and all those good gases will seep out through. It’s funny that you mention tinners rivets, kinda looks like that is what is holding the hood together currently, lol. Is there a recommended gauge of sheet for the hood? Obviously I don’t want something too flimsy. I know it will need to be big enough to handle the draft and I would think the one on there is a good reference but, without running it, I can’t really know for certain. It is a Lancaster blower! I know I can get it moving, ATF is what I used to gently lubricate the gears in the last one I brought back to life. I think the killer is the multiple cracks in the gear housing, the air connect, and the mount for the arm to the forge. I can get more pictures up soon. -

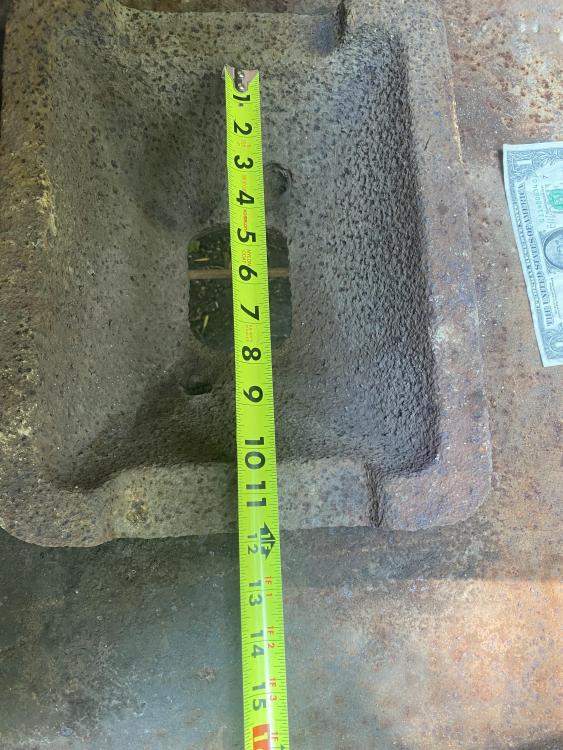

I was encouraged to start a new thread so…here we go! I recently purchased a coal forge as I want to being the process of transitioning off of propane over the next few years. She is huge 43” x 32” x 32” (overall dimensions) 8” x 10” (fire pot) In regards to clean up I intend to : -soak what I can in evapo-rust -wire brush with angle grinder -hit the rough outer edges of the bed with a flap disk -redrill the holes for mounting/reattaching the clinker breaker and ash vent - paint the outside underside and legs (at this time) prime and paint with rustoleum -I am considering, once the coal bed is rust free, painting a few layers of Satanite over it, is this wise? Should I do something else entirely? Or change my plan of attack? -hood will need replacing, it’s pretty rusted through in some areas If there is something I absolutely should not do, please let me know! The bed is marked 41-42, I am guessing it’s manufacture date? I want to preserve history and bring it back to life, not ruin it irrevocably The blower looks like toast, maybe good for parts down the line? It’s missing a big chunk and is seized pretty well. I have restored a blower in the past, we will see what comes to fruition. in the last 2 pictures, to the left of and slightly behind the blower, is an arm that bolts to the belly of the forge and holds the blower. Has anyone ever seen a beast like this? What are ya’lls thoughts on this beast and what I can/should NOT do to bring it back to life? Love, Peace, and chicken grease!

-

Wondering what ya’ll think of forging things to the point of removing the witness marks. I have always been of the impression that a master removes the whiteness marks through the fabrication process ultimately resulting in a work that appears to have always been as it appears…i.e. the witness marks show the craftsman’s work, process, mistakes(whether unintentional or purposeful). My father and I were having a nice little banter back and forth as he believed that the subtle markings helped to reinforce the handmade quality, that making something to the point of it being devoid of human touch makes it appear as though it was mass produced on/in a machine. I argued the latter, forging/fabricating to that level of mastery is kinda the goal, right? Who’s with me!?!

-

It followed me home

TastefullyPeenedIronWorks replied to Glenn's topic in Blacksmithing, General Discussion

Not exactly blacksmithing, per say, but, found this bad boy while exploring Lancaster County, PA, home of Hershey Chocolate. This is one of the aluminum trays that they mold 5# bars of Hershey’s Chocolate into. Never bought one of those massive bars but this tray will never leave my shop, it’s absolute fire. -

I am familiar with chasing and repousse. I have watched some cold working of metals and really find it both inspiring and mesmerizing. I will need to look up and research fold forming, that’s a new one to me. I can occasionally get my wife to hang out with me in the forge for small amounts of time but nothing too prolonged. She is primarily a healthcare worker and does not quite get my passion for forging but does understand the desire to create.

-

Blacksmithing is the best job I’ve EVER had and I hope it becomes a full time gig; if I’m that lucky I’ll never ‘work’ again. The flowers are all painted up, they are selling - that’s a start. The snails are a joy to make, made my wife one that fits in her palm. my daughter gets involved in her own way(s). (She is 9 going on “19” and certainly acts that way). She is an unbelievable source of encouragement, always holding my projects and giving me great feedback. She makes little things with play-doh and modeling clay and I often remind her that she could learn to do that with a hammer, it translates so well.

-

Show me your blacksmith pets

TastefullyPeenedIronWorks replied to Glenn's topic in Blacksmithing, General Discussion

Frosty! Yes! Their safety is often overlooked, I think. (Someone will correct me if I’m wrong). I have often thought of cutting my pooch a leather jacket for the shop. He is 4 now and I have been thinking a lot and trying to figure out when the transition happened of looking at my dog as an investment to now seeing him as a valued and treasured friend. I grew up with dogs but never personally owned one (my wife might disagree with who owns who). I am thankful for my furry friend. P.S. petting your dog is great therapy in between heats, for you and them!