Seamus

-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Seamus

-

-

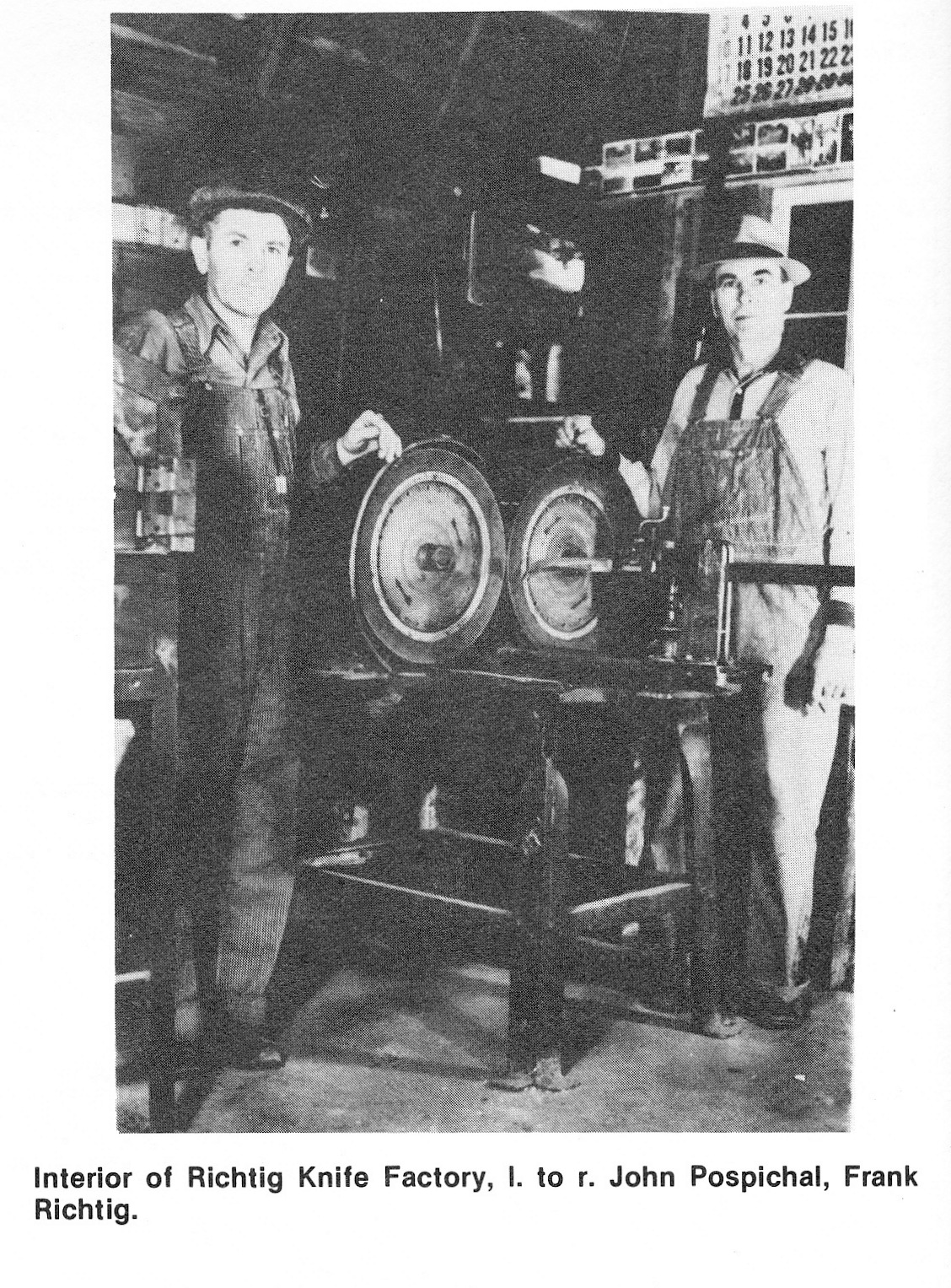

Can anyone identify the machine this fellow used to grind his blades?

The accompanying article says he was a stock removal man.

Looks like the machine is set up to grind two sides at once

and presumably create a hollow grind.

Is this something he fabricated or something he

modified, or...?

The article proper

https://clarksonhistory.wordpress.com/2013/05/06/secrets-of-the-dead-the-richtig-knife/ -

Okey, obviously got the right guys to talk to here.

Thanks for the image link G.O.G.

What I see looks like a choker chain with a hand madegrab hook on one end and a large link on the other.

I'll show her that and see what she says

Googling about a bit after I posted here, I did find

http://store.chainsawr.com/products/keyhole-chain-hook-loggergrab

and

http://www.northerntool.com/shop/tools/product_479598_479598

No way I can make them that cheaply, but I'll see if that's what she wants.

Maybe we can trade something. She's got an industrial Singer sewing machine

and I have canvas I'd like to mend.

Nobody, I followed the link, but my Google Book skills aren't that good.

All I can see is an excerpt from pages 141 and 148

How do I get it to show me the pictures on pages 55 & 60 ?

Notownkid, got your email. You're on the right track.

She does wood turning, and uses the ponys to haul logsnow and again. Nothing big/heavy she said. I expressed my

concerns about liability, and that she'd be better off with genuine

logging hardware, but she's a fairly small woman and on the north

side of 50, so she's not about to get involved with anything over 200 lbs

or so she says. Anywho, it's an interesting project for me, nothing ventured

nothing gained. Go ahead and send the pictures to my email if you can.

I had thought I had set up things so I'd get emails telling me when someoneanswered my question, but it doesn't seem to be working. Maybe I did it wrong

or maybe Yahoo dropped the ball.

More anon

-

Woman with Haflingers wants a "bitch hook"

No, that's what she said, honest.Looked it up, and found

bitch hook n. a curved metal device used with a chain

to hold or secure lumber or other things,

or to brake a sled on descents. Also bitch link.

Editorial Note: The unpublished manuscript for the Lexicon of Trade Jargon

(circa 1938-39, now at the Library of Congress) includes in its section on

“Lumber Workers’ Slang and Jargon” an entry for bitch chain

and defines it as a “Heavy, short chain with hook and ring,

used to fasten the lower end of a ‘gin pole’ (q.v.) to a sled or car when loading logs.

bitch link, “In logging: a pear-shaped link on the end of a chain,

larger and heavier than other links.

When the chain is run through an opening

a choker can be looped through this link to secure it

Okey. Anyone have one, or can direct me to a picture of same?

-

D'Oh!

You're right Doc! -

Don't find a technique forum, so posting here.

Apologies if this isn't the right forum.

How do you upset to one side of a square rod?

I've wanted to make a pair of holdfasts for a joiners workbench

since I first read about a guy named Rob Tarule

using them in an article in Fine Woodworking.

They're very fast and flexible compared to a vise.

Since I read that article, Chris Schwarz has gone on a tear

and popularized the Roubo workbench, so much so that

you can't hardly swing a dead possum without hitting

one on the Interwebs.

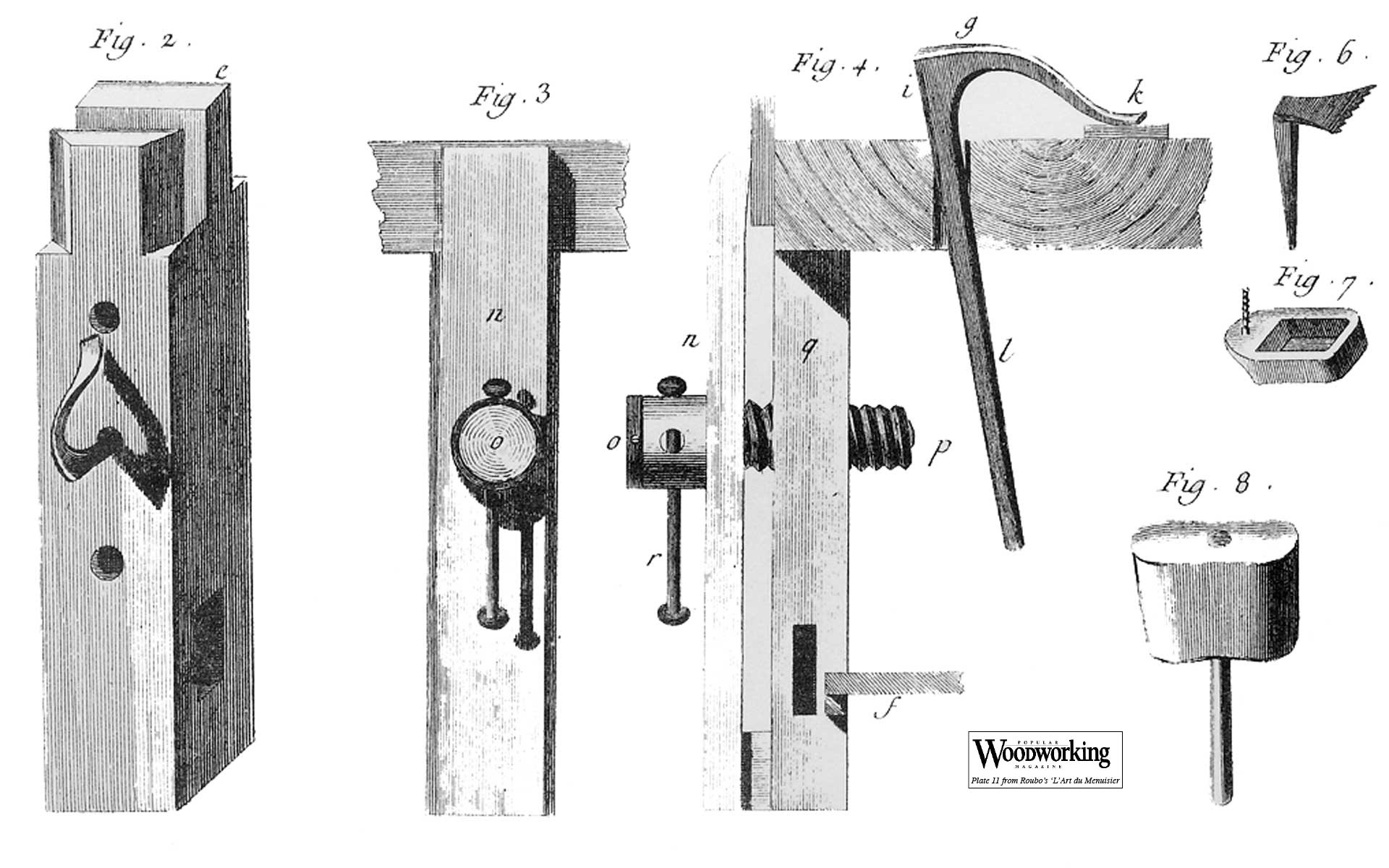

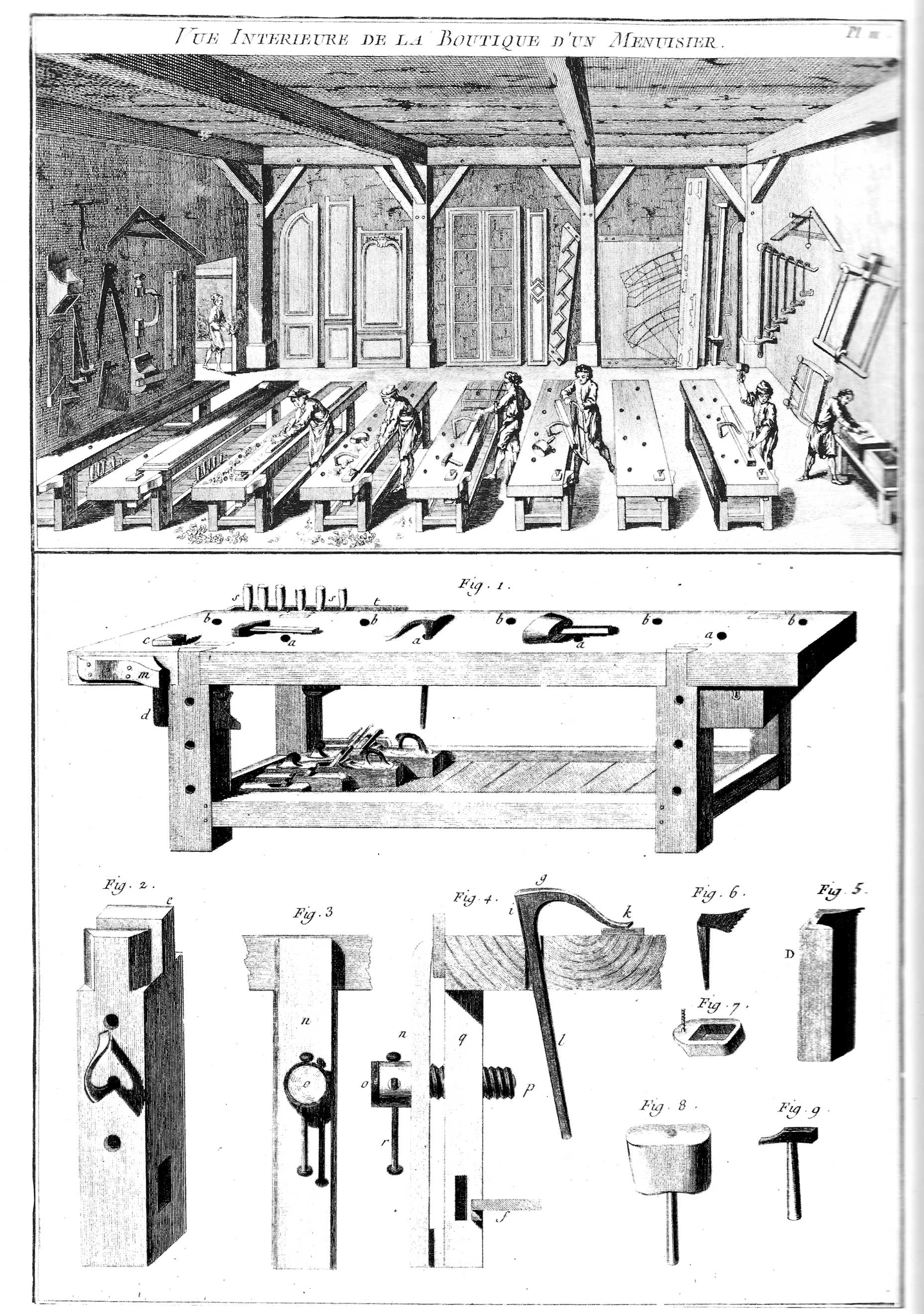

Peter Ross recently made a close if not exact replica

of the holdfast illustrated in André Jacob Roubo's

L'Art du Menuisier, the book that started the whole thing,

for Schwarz and you can see the original illustration here

and Ross' results here

http://www.popularwoodworking.com/woodworking-blogs/chris-schwarz-blog/workbenches/that%E2%80%99s-not-a-holdfast

and some "work in progress" shots here:

http://www.popularwoodworking.com/woodworking-blogs/chris-schwarz-blog/workbenches/straight-from-the-frenchmans-mouth

In the first illustration of Ross working on the bar

it looks to me like he has upset on one side

midway down the bar. The upset is to make

the mass for the shoulder of the head.

I've upset on end, but not midway and not

to one side like that. What's the technique?

I know you can make a holdfast by bending

but that's not what I'm interested in.

Thanks for any suggestions -

There's a few pics

here

Groups -> projects -> forge

but click on the preview image

in the right hand column first

because the full size ones are quite

large and bound to tie up your

machine if you have a slow connection -

Either not too many have a favorite, or there are a lot of us using power/air hammers? Or just a lot of Strong-Silent types...

I just got a Farriers rounding hammer no name, weighs 2 lbs at a junque shoppe for $5.00 or so last month. Haven't tried it yet, but am looking forward to it. The Japanese hammers strike me (hyuk hyuk hyuk) as interesting, but they're pricey.

Also got a 40 oz. Plumb with an 18" handle at the aforementioned junque shoppe. It has an uncommonly sharp peen, to my eye. I splurged on a Sears/Craftsman Cross Peen because I was amazed how good the handle felt and thought I would use it as a pattern/reference for sanding the rest of them. It is simailar in profile to the Plumb, but not as sharp.

The handle more than anything will I think decide for me what my favorite is.

What I don't understand is why the cross peen is so common and a diagonal or straight peen is not. Standing at the anvil, I can immediately see the advantage to the diagonal and straight over the cross. They would line up better, or more naturally, for me anyway.

The Hofi and the Ozarks one are just waaaaaaaaay outta my league. -

Outside, covered, 55 gallon drum(s)

under an open shed roof. -

Yeah, they've been around awhile

Have not taken a class there, but hope to.

Wish there were more like them - i.e. not just

blacksmith classes but traditional farming methods,

wheel wrighting, dry & wet cooperage, etc. etc. -

My buddy in Maine

who posts on an old tools group

made himself a framing slick for

an upcoming T.F. class/project.

I asked him if I could post the story

here and he agreed. FWIW

Galoot is an honorif meaning someone who

eschews the use of electron burning tools

when assaying woodworking projects,

preferring instead to hew to the line of our

forebears and use old or antique tools.

Saint Roy is Roy Underhill of the Woodwrights Shop

on PBS. I believe that's all the decoding necessary

Gentle Galoots,

Short version: got more gifts, finished a slick

Long version: I received two more packages from Galootaclaus yesterday,

one a very fine old machete that fits my hand perfectly and actually

swishes when you swing it, the other a very cool Millers Falls carving

set in a nifty plastic box that opens as a stand. It includes a tiny

slipstone. Here's a picture:

Galoot Image Central

The puddytat didn't want to move out of the studio so I made him smile,

meet Bo, everyone :>

Thank you Galootaclaus, thanks very much!

In the same mail I received the St. Roy DVD that Michael made for a

bunch of us Royless Galoots. I spent a happy afternoon watching Roy

FOR THE FIRST TIME, he sure is something. Thanks so much Michael,

you're a king!

I finally finished the slick I made, it's about 3 feet long with a 2

1/2" blade that's about 8" long. The blade is a piece of leaf spring

with about a 20 degree edge. The ferrule is a 1 1/4" piece of copper

water pipe and there's a piece of hammered brass followed by a piece of

leather between the shoulders of the blade and the wood. The handle is

brown ash and I know how tough it is because I whacked it quite hard to

get the blade seated and it was totally unaffected. The whole thing

weighs about 4 pounds. Here's a picture:

Galoot Image Central

and a closer look here:

Galoot Image Central

The picture make the shoulders look slightly off, but they're not, it's

just the angle of the camera and the fact that the blade is bent at the

tang (5") in the traditional fashion.

Sharpening this baby has been a huge job since the steel is super hard

and I'm doing it by hand. I still have a bit to go and then I need to

make a blade guard.

Happy 2007 everyone!

Adriaan

"This is what you shall do: Love the earth and sun and the animals,

despise riches, give alms to every one that asks, stand up for the

stupid and crazy, devote your income and labor to others, hate tyrants,

argue not concerning God, have patience and indulgence toward the

people, take off your hat to nothing known or unknown or to any man or

number of men, go freely with powerful uneducated persons and with the

young and with the mothers of families, read these leaves in the open

air every season of every year of your life, re-examine all you have

been told at school or church or in any book, dismiss whatever insults

your own soul; and your very flesh shall be a great poem and have the

richest fluency not only in its words but in the silent lines of its

lips and face and between the lashes of your eyes and in every motion

and joint of your body." - Preface to Leaves of Grass - Walt Whitman -

You can see what I'm dealing

with by flipping through my snapshots here:

Flickr: Photos from coalandice -

Forgot to add the link

to this one:

Gibbins Aprons

Darned expensive

but nice pattern and weight -

It never occured to me to wear one

till the guys I practice with on the

weekends mentioned it. I showed

up the next week with my favorite,

but they didn't think the Bar B Q stains

were in the right spirit. -

Very nice detailed pics

glad you posted them

I have a Cannedy Otto 00

that the previous owners father

adapted to use as a lathe, like yours,

lying on it's back.

Now I've got it and sure would like to use

it vertically, but he tapped the original chuck

out to 3/4x16. Jacobs makes a chuck tapped

to take a stud that size, but they want

in excess of $100 for it retail. I do have

a nice Jacobs for up to half inch, but it's

tapped for 1/4x20. Any suggestions

on how to mate the two?

Thanks!

p.s. HOW do you get pictures to show up in a thread? -

and good photo composition on the

2nd shot, near-far, etc -

Oh...sorry I brought it up

I was reading the one thread

about hand forged hammers

and kept seeing "no need..."

and thought maybe the server

or whatever had taken a hit.

Just found out today they

had lost power in the northwest

for close to 3 days in some places -

Hunh? Wuzzat mean?:confused:

-

Hi

Skipping to the bottom and posting before

reading all that has come before. Hope that's

okey. Here's what I am using:

I hope to clean it up someday but am not at

all in any hurry to do so. I read Charles McRavens

book and based on what he had to deal with

I don't feel too bad. I certainly am not about

to attempt anything until the quality & quantity

of my work is such that I can justify the expense

to "repair" it or get another one in better condition.

That said, how bad is it folks ? And since I have a

piece of 4150 - 5/8ths thick and 15" x 6" long do

I want to hang onto it (the 4150) and use that to

reface it? Thanks

BTW - how do you post images IN the text

of a message? I tried and it didn't work atal -

-

BEST demonstration of

caloric content I do believe

I've ever seen! -

W o W !

This is most exceedingly cool!

We all know they worked on huge honking

pieces like this, but to actually SEE it is something

else:

YouTube - Broadcast Yourself. -

Beer.

Yeah, definately

Beer. -

-

Hope this helps

I have two portable forges...sort of

One is a Centaur Forge Truck Model B with electric blower

I got it used for $50.00 and while the firepot & tuyere are

worthwhile, the rest is, uh...anemic ? enough that I am glad

I did not pay full price for it. I had intended to use it as my

portable/demo unit but

1) can't count on electricity at demo sites

2) the electric blower is spot welded to the frame/stand

so I couldn't easily mount/dismount the electric motor

as part of the set-up/breakdown without modifying it

something I didn't have time for at the time of acquisition....

3) The tuyere port where you would afix the blower cannot be

aligned to the right or left - it sticks straight out at you or

180 degrees away from you as you stand at the forge

no way to orient it at 90 degrees. This complicates attaching

your portable blower

4) Bought a portable hand cranked blower and it came with a 400

whirlwind firepot & tuyere and all the fire brick I could haul away

Wound up making something like this, only bigger and the firepot

sits flush with the top

Building a Portable - Bellows Fed, Forge

pictures of mine here:

Implements of Destruction... on Flickr - Photo Sharing!

In short - get what you can. I would recommend one, but have

not been able to afford them since they seem to go sky high

at auction around here...

Trying to identify old grinder

in Grinders, Sanders, etc

Posted

Well thanks for the link

That's sort of what I was thinking of doing