-

Posts

152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SFC Snuffy

-

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

BenW, that looks like a great start to a chess set! -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks, all, for the kind words. The conference is over, so there'll be no classes in the near future. That was my first time swinging a hammer since March 2020. Hopefully I'll be able to get back to forging soon-ish. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks! Did I mention this was my first-ever forge weld? The instructor started the class by going through all the procedures and elements and how they relate to a smith's basic skills, then said "We'll start with the forge weld!" We all kind of looked dumb and shuffled our feet, with each of us thinking we were in over our head. With help from the instructor, though, all of us stuck our weld on the first try. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Took an "intermediate" blacksmithing class at last weekend's Blacksmiths' Association of Missouri (BAM) 29th Annual Ozark Conference in Sedalia, MO. This candlestick was the result, and while there are things I might have done differently, and others that I would have spent more time on if I weren't in a classroom setting... I'm generally happy with it, particularly for never having made anything like it before. -

Forge welding close-ups

SFC Snuffy replied to TechnicusJoe's topic in Blacksmithing, General Discussion

Wizardry and black magic. Many thanks for the video, sir! -

Beautiful work, sir. Well done!

-

Recommendations for smiths

SFC Snuffy replied to Cooperblacksmith's topic in Blacksmithing, General Discussion

The Center for Metal Arts in Johnstown, Pennsylvania has an internship, which might interest you. The internship competition closes January 15th, so don't wait too long to apply. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks! That means a lot coming from you folks. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Here's the taper on that 3/4" bar. I decided to put it on the diagonal just to make it more interesting. The fuller's a little ragged, but it will clean up with a file I'm sure. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

I stopped by the local steel supplier for some pieces to finish up a project. I got some 3/4" square HR to be the upright portion of a stand for fireplace tools and put a nice taper on the end at the forge (pics to follow tomorrow, hopefully) and a piece of 1.5" square bar that will become the base. A friend at work is going to split both ends of it for me with his bandsaw and drill a 3/4" hole in it. I should have a little of that 3/4" bar left over... think I could drift that round hole square? Or would I be better off with filing it to shape? -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Can one "acquire" surplus manhole covers? They don't really wear out, do they? -

That's a fantastic story, sir. Thanks for sharing!

-

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Slanwar, I'm not native to Missouri but I understand hickory to be plentiful around here. The sawmill where I bought my 4x4s offers white oak, red oak, walnut, pecan, hickory, and ash, all custom cut. They also buy standing timber. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Made some more progress on the stand for my swage block. I wish now I had done some things differently, but overall I'm happy with the results. It's all glued together and bolted, but I need to fabricate and install the retaining brackets on the corners, paint the bottom with exterior latex, and treat the top & sides with deck sealant. So little time. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

I made some progress on my swage block stand, though I ran out of time. I'll have to try to finish it next week. I ran the rough-sawn 4x4s through the jointer to get a good fit-up and started boring holes. The plan is to run 1/2" all-thread through the blocks in both directions to help hold everything together. -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

Not *in* the shop, per se, but I picked up some hickory 4x4s today with which I intend to make a stand for my swage block. Hopefully I'll make some progress on Tuesday (first day of my weekend). -

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

CGL, don't we all! -

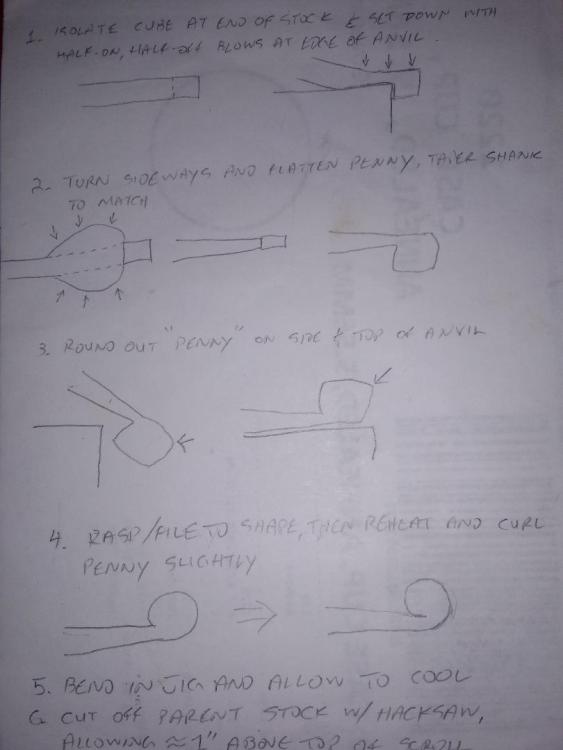

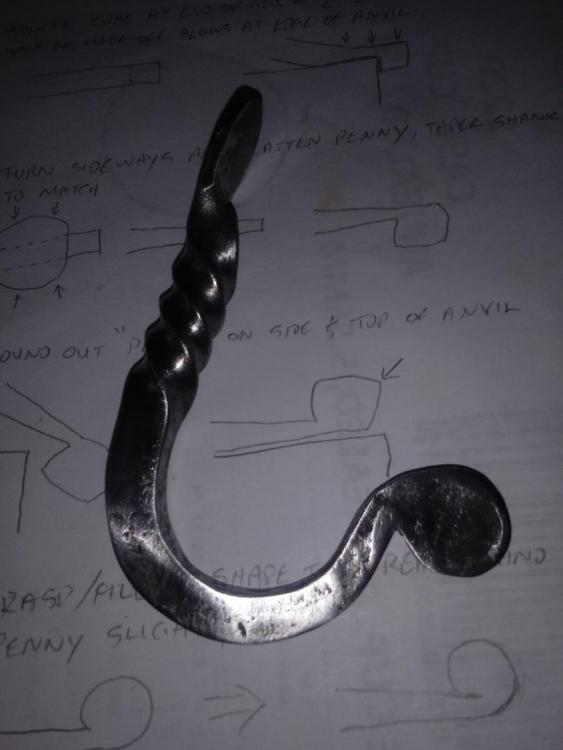

I'm at the early end of my smithing hobby. For simple things like hooks, I'll usually keep a design in mind, but most of those are one-offs for me as I'm not making items for sale, so if it doesn't turn out quite as I envisioned it isn't the end of the world. It's much more challenging to make multiples of an item as identical as possible. I've recently started branching into more complicated projects (by my standards), and I've found it helpful to do a workup of the process. For something with multiple pieces, such as the fireplace tools and stand I'm working on, I'll sketch it out or even do full-size drawings. I'm neither a draftsman nor a sketch artist, but I find that rendering my ideas is both mentally stimulating and good for working out how a thing should come together. I really should take a page from Chris and Pnut (and many others on here) and try some things in clay before heading to the forge. I don't get much time at the forge, and when I do it's shared with another smith. I should work harder at being more efficient.

-

The place I work has an awful habit of referring to things by manufacturer names. Several of my coworkers' minds were blown when I told them that the "ring-feeder" holding the turret tool ring in place was, in fact made by the German company Ringfeder. Even more so when I (helpfully) explained that not all couplers are Lovejoys (ours are actually provided by a different manufacturer, I think). It's an older facility - been in operation since 1942 - and while most of the equipment in my building is more modern than that, terminology gets handed down in a generational fashion. Even when it's wrong.

-

My brain has the hardest time differentiating between channel locks and vise-grips, and I will often say one name when I mean the other.

-

Show me your Bottle Openers!

SFC Snuffy replied to Arbalist's topic in Blacksmithing, General Discussion

Oh, nice! I've been wanting to try setting it on the diagonal, but my tooling isn't really up to it at t he moment. -

Those are beautiful. Well done! How difficult were they to form? Raised or sunk?

-

If you're looking for smallish pieces for knives and small tools, most knifemaking supply or blacksmithing supply websites offer stock in a variety of alloys, shapes, and sizes, as does the ubiquitous mail-order web juggernaut. In all of those cases, you'll be paying for shipping as well as retail prices.

-

What did you do in the shop today?

SFC Snuffy replied to Mark Ling's topic in Blacksmithing, General Discussion

I made some hooks today. I'm not entirely happy with the scrolls but I'm learning, albeit slowly. These are made from 3/8" square HR. -

As someone at the opposite end of the spectrum, that is, a novice who's still looking for a forge and anvil of my own; I can attest it's sometimes dispiriting to see people with large collections. I recall watching a video of someone "blowing/shooting/firing" an anvil into the air and feeling a bit put out. I'm not operating under any delusions about my "entitlement" to any of these things, but I confess to being irritated that someone would treat an anvil so casually and callously when I so badly want one of my own. Were I better-positioned (i.e. wealthier), the shoe might be on the other foot. As it stands now, I'm hungry but no longer young and blessed with neither an over-abundance of free time nor disposable income. Put like that, it makes me wonder why I'm trying this at all! It's late for me and I'm tired after work, so I'm certain that I'm rambling. Mea culpa, mea culpa.