HP500

Members-

Posts

95 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by HP500

-

Nice find this weekend - William Foster

HP500 replied to HP500's topic in Anvils, Swage Blocks, and Mandrels

Thank you. 129 lbs. No plans to do anything to it other than wire brush it to get the rust off and hit it with some BLO. Thanks Thomas, that's good to know. We also have a very nice 200 lb Trenton so I'm curious to see how it compares. I was pleased to see that it wasn't abused too badly for its age and that the horn is in really good condition. It will be better for making bottle openers than what I'm using now. I need to make a stand for it, so I hope to be able to do that soon so I can test it out! -

Nice find this weekend - William Foster

HP500 replied to HP500's topic in Anvils, Swage Blocks, and Mandrels

Thanks guys. For those of you who have worked with William Foster anvils, how do you like them? -

Nice find this weekend - William Foster

HP500 replied to HP500's topic in Anvils, Swage Blocks, and Mandrels

Thanks! I'm looking forward to giving it a workout very soon! He also sold me a Reed 104 1/2 vise for $25, so it was a good weekend. -

Nice find this weekend - William Foster

HP500 replied to HP500's topic in Anvils, Swage Blocks, and Mandrels

Thanks! I'm just curious about the date. I'll give the flour trick a try. I put it on a scale and it weighed 129 lbs. -

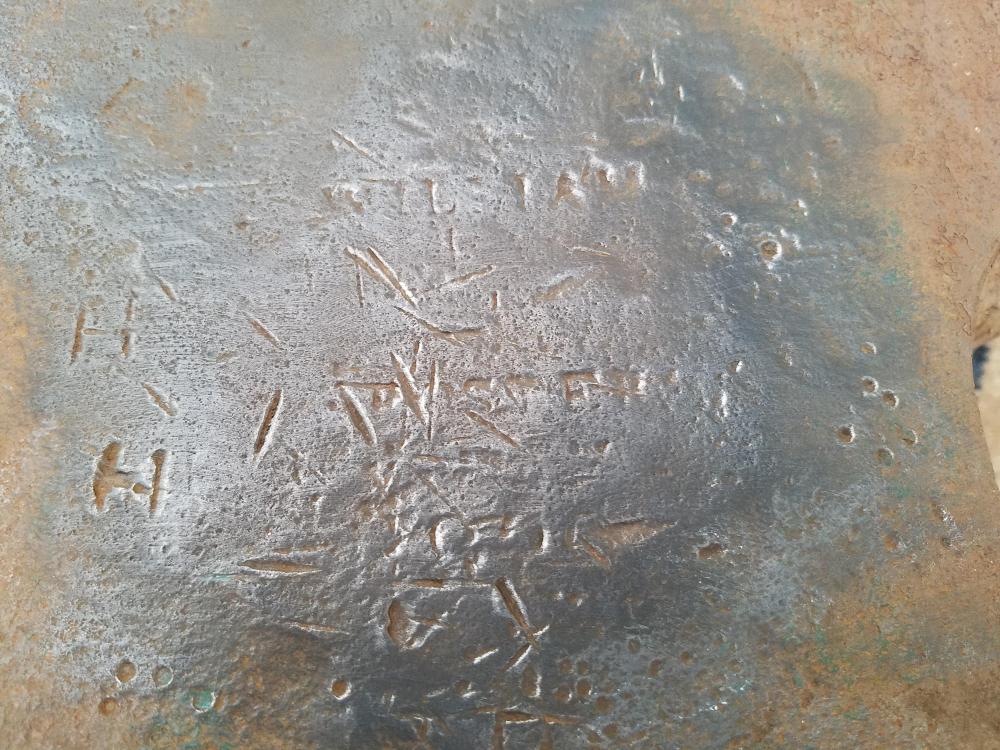

My neighbor needed help moving some misc. steel bars he was given by a friend of his and asked me if I would help him load it up. I said sure, no problem. When we got to his friends place, I noticed a rusty anvil sitting in the corner of his friend's shop. I asked the guy if he would be willing to sell it. He said that he never used it and that I could have it for $100. Hmm....let me think about it - OK. I couldn't see any markings on it at the time, but when I got it home and hit it with a wire wheel, I could see that it was a William Foster. It appears to be in good condition, especially for its age. Some pics are attached. I read that WF anvils are all dated. I think there is a date in this close up picture, but I can't tell for sure., Can anyone make it out? Thanks!

-

Best steel for this project

HP500 replied to MilwaukeeJon's topic in Axes, Hatchets, Hawks, Choppers, etc

I don't know if it is the "best" steel, but we have had very good luck making these out of chunks of leaf spring. -

Some pattern welded test pieces

HP500 replied to FieryFurnace's topic in Blacksmithing, General Discussion

Very nice! -

Good info, thanks!

-

Yes, it is an attached garage. Good idea, thanks!

-

Will do, thanks!

-

I live in the northeast and it will be relatively cold here for the next 4 months or so. I don't have a shop, so I wheel all of my equipment from the garage out to driveway and back again. I would like to use my new propane forge in the garage throughout the winter in the evenings after work and when the weather is bad. I have a two car garage and can forge with at least one of the large doors open. I can also get a cross breeze if I open the back man door. I assume that this will be enough ventilation to prevent CO poisoning, but I'd like to install a CO detector just to be sure. The problem is, all of the CO detectors I've found have a minimum temperature rating of 40 degrees Fahrenheit. We won't see temps above that here until April. Does anyone know of a low temp CO detector? I came up empty with an online search. Thanks.

-

Have you decided on a design yet? If not, take a good look at Wayne Coe's build information.

-

Yup, that is a bounce house blower. I wasn't sure how well it would work, but I found it at a garage sale for $5 so I gave it a shot. It seems to work well. This is my first gas forge, so I'm still learning how to use it. I haven't tried forge welding yet, but I hope to in the next week or so. When I played around with the gas pressure and air flow settings while testing, I was able to get a piece of angle iron to start to melt, so I should be ok.

-

Thanks!

-

Recommend stock size for wrapped eye tomahawk?

HP500 replied to Goods's topic in Axes, Hatchets, Hawks, Choppers, etc

I've been using 1.5" x 1/4" x 10.5 long mild steel and forge welding in a piece of 5160 for the bit. It works for me. -

I recently completed a ribbon burner forge based on the Wayne Coe design and bought the build supplies from Wayne. My forge is very efficient. I have a 0-30 high pressure regulator and I'm forging at less than 2 psi. In fact, once the forged gets up to temperature, I can turn the gas off at the regulator, crack it open again just enough for the forge to re-light itself and just keep the flow there. I don't know what the psi is at that point because this gauge doesn't register, but I'm guessing I'm at or below 1 psi. I've used the forge about a dozen times so far and have barely used any propane.

-

I built mine so I can reach into the opening with a pair of tongs with my forearm bent at 90 and parallel to the ground. I played around with different heights and that was comfortable for me

-

Good steels for fire steels

HP500 replied to Bill in Oregon's topic in Blacksmithing, General Discussion

I've also had very good luck with W1 square stock. It sparks like crazy. -

Nice job!

-

Thanks!

-

Thanks!

-

Thanks for the info!

-

Very nice! What made you decide to move away from 5160?

-

Can anyone recommend a resin for making Micarta that stays clear and won't darken your starting material after it drys?