Stew1803

-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Stew1803

-

-

Doors cant go on the side or back frosty due to the way out property is laid out other wise I would put a gable door in, a car wont be stored in there, but I weld up a lot of machinery and vehicles so its ideal to be able to get them in the shop, I'm wanting any metal work to be carried out in this shop as we have valuables in the other that I do not want to burn down in an accident, and this shop will be stand alone a good distance from them.

if I swap the sides the racking and work benches are at then I would be working in U shape around the forge/ anvil area. But in an ideal world I would put a roll up on the end but property boundaries and woodland I'm not entitled to disturb prevents this unfortunately.

-

Coming from Scotland I say that -

I see more gas forges than coke or coal,

almost all coal or coke forges ive seen have been bottom blown,

I use and know others to use borax,

Old fashioned pillar drills are far more common

various carbon steels are extremely easy to find,

it took me all of five minutes to find myself a 2x72 and belts, but I ended up with a homemade one due to costs.

Railroad spikes are hard to get though so agree on that part -

Hopefully you can see the attached file, The smiddy will be around the size of a 3 car garage (depends more on funds and how easy I can get trusses rather than ground space really)

I think I have the work triangle to where I want it, its similar to what it is now (Excluding press and power hammer they will be later additions once I build them)

-

Just to drop in on the bent sword, I believe from what ive read and understand was that the Vikings felt that a sword was a weapon that had its "magical" powers and often named them and respected them. And it was felt that a sword taken from a warrior killed would mean that it would bring bad luck and that the original owner of the sword would be waiting in the afterlife for vengeance. To prevent this the swords were bent and buried with the owner, enemy or not.

I understand the religious beliefs of these people was very complex and there wasn't just an afterlife etc, and I'm sure I could have worded it better, but in essence I think it was done out of fear of the consequences in the afterlife. -

Hi all,

Not posted in a while but am seeking some advice.

I'm going to be moving out of my 300 year old shop sadly as its being converted into a house (can be seen of Page 20 of show me your shop), And building a new one, it'll be a wooden frame and walls and tin roof. Roughly the size of a large 2 car garage (maybe a little bigger) with doors big enough to fit a car in just out of ease.

So how would you set it up inside? I will have both a solid fuel and a gas forge, two anvils, 2 post vice, belt grinder, welder and all of the accompanying tools and materials. And there will be a small power hammer going in one day. -

Thank you for the reply, I wasn't sure if it was all wrought or had a face.

-

-

10 hours ago, Jonnytait said:

Nice smiddy, good to see others in scotland here

it's great to see I'm not the only one over here!

would love to have a catchup if your free anytime?

also noticed your in Shetland, I work at Sullom voe.

-

-

I hope this can be of help, Just try not do what I did and "accidentally" print the practical blacksmith books at work (They are quite large) haha.

-

http://www.craftsmanspace.com/free-books/blacksmithing-books.html

I suggest all look through this website, books can be downloaded and printed for free. it has various skills, forging, woodwork, mechanician etc, very good.

-

I'm 24, grew up and live in north east Scotland, I got a basic "Shop" class in high school when I was 15/16 but it was very basic, no taps, or taught about steel types, hardening processes etc. I taught myself that and then proceeded to teach the teacher. (I have an amazing father who has taught me endless amounts luckily)

I was never any use at maths, I can do it but it takes a very long time. T can get there if I have a practical explanation, eg. gear ratios, building houses, technical drawing etc. I know my times table up to 5x and don't know trig or much else to be honest. but I do have an apprenticeship (time served) in Mechanical Engineering that I worked extremely hard for, and I also think that's one major problem with my generation is they lack the will to try hard for something (Exceptions obviously).

I always carry a Zeus book with me for hard equations, tapping sizes etc. which helps tremendously.

On that note, i work with an "Engineer" (HVAC) who claims to be one of the best in the industry yet I had to teach him how to drill holes properly with a battery drill because he kept snapping my drill bits which were 10mm (0.39" ?)

-

Prices were good and things were easy to find about 5 years ago when I started, but I also had no money (apprentice wages aren't great), but now, after all these shows on tv the prices have hiked up and are not worth it now, my time making things is less than the cost usually.

-

Ill certainly get some photos of the outside, (Im working offshore for another week and half unfortunately) though it has been renovated over the years obviously. our local original blacksmith shop for the farming area here still stands about a half mile from me. I would imagine it would be even older, though it is now only used to store spare farm equipment.

And if you're real lucky with a metal detector around some of the farms you will find buried anvils, there was a time when blacksmith tools couldn't even be sold so people scrapped or buried them.

My two anvils (one larger than in the photos with a cracked face) cost around £40 ($55) and the leg vice was free. -

Thought I'd show some of you my smiddy (smithy)

It's a farm bothy and the original structure is from around the mid 1700s.

it's been lived in, used as a piggery, for chickens, as a storage shed and is now my smiddy.

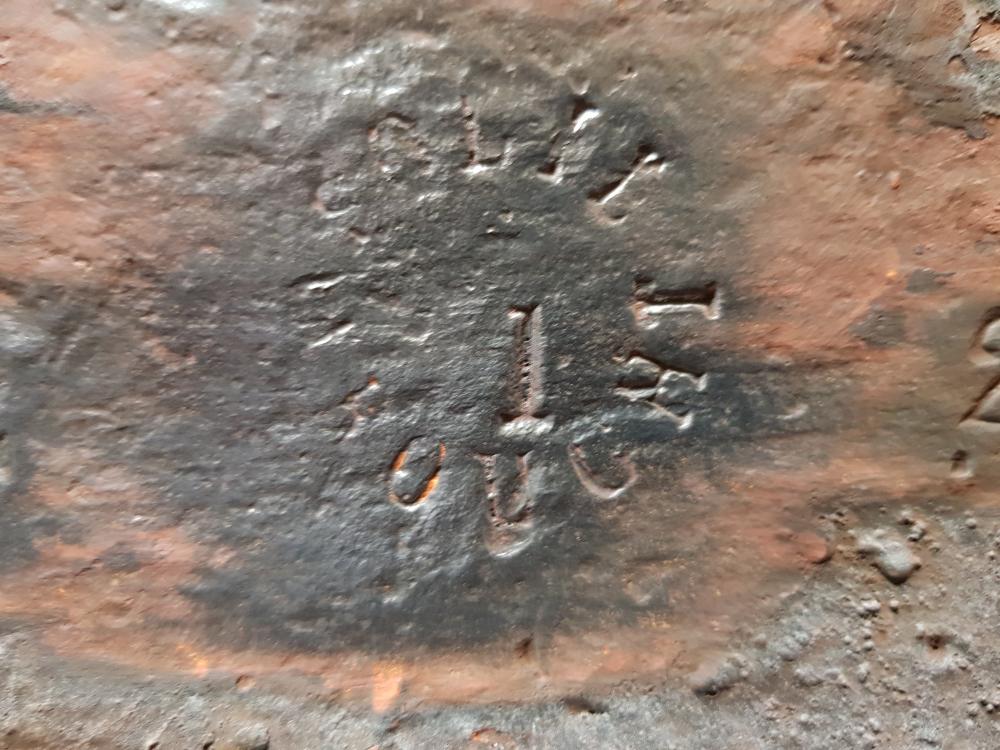

also is a photo a wrought horse shoe I dug up in the fields the other week, the area has been farmed for as long as human have farmed in Scotland so has a bit of history.

-

itll almost certainly be the tracking wheel needing crowned, as long as you've aligned the other wheels using a straight edge to each other.

-

I'm from North East Scotland, and I can think off the top of my head at least 5 places within 100 miles someone could get a formal apprenticeship in blacksmithing(This would include college and papers), ranging from tool smithing to large industrial stuff.

I also know of tens if not hundreds of different "blacksmiths" (Smiddy's) locally.big demand here, though most of their work is made up of fixing farm machinery nowadays.

Stew

-

Ah okay, my mental map of England isn't great

-

when you work offshore and phone home to make sure your shop is okay.

-

my recommendation for an anvil is a forklift toe(tine), if an anvil is out of the question.

does Alec Steele not live an hour or so away? he may be able to point you in the right direction, he seems like a decent bloke.

-

I use two ventilation fans, 8" in dia. this woks extremely well for me, I have each one on a rocker switch, so its either on or off. but this works well for me.

-

do you know which region you wife comes from Steamboat?

and yes it basically means smithy.

5 hours ago, Steamboat said:My wife and I hope to make it over to your side of the Big Water again sometime in the next year or so. She'd like to have a look at the places her ancestors came from.

As to the term "smiddy," the closest equivalent here that I can think of would be "smithy" for a blacksmith's shop, such as used in Longfellow's poem, The Village Blacksmith.

Steamboat

-

there is certainly a lot of character locally. some fantastic metal work or some of the old churches here, big old doors and gates etc

Id love the chance to visit the states for a long visit, I think some of the scenery you have is amazing. plus im an avid shooter and you certainly have better laws regarding the use of firearms, plus your allowed to carry knives etc so I believe.

but there certainly is plenty history in America in regards to blacksmithing, and you lot have access to perhaps better steel works than over here, especially since a lot of steel is American made, we have no steel industry left here anymore.

and I would certainly be willing to give a bed (and use of my workshop) to any smith who wishes to visit here.

-

most modern houses here are not built to last either.

but there are a lot of old buildings so its not really a worry

UK-US blacksmithing differences

in Blacksmithing, General Discussion

Posted

Oh that is a good bit past the border there, not easy to send raiding parties over so I don't go down that far though I must take a trip down there, ive been told its a great part of the world.

though I must take a trip down there, ive been told its a great part of the world.

I guess most of the people around here are farriers that do smithing on the side so that explains the gas, and there are few people that do it otherwise in my are bar me haha