-

Posts

349 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Zeroclick

-

What did you do in the shop today?

Zeroclick replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks, I will have a look how it holds up, I have another one to make so might go for more of an angle. It makes sense with triangles being the strongest shape. I'm hoping it will hold up as the top bar is 10mm and the support is 8mm, Thank you -

What did you do in the shop today?

Zeroclick replied to Mark Ling's topic in Blacksmithing, General Discussion

I made this last night, my wife wants somewhere to plant her strawberries so I made her a bracket. It was my first go at tennons, I did them at the edge of the anvil and using the bolster plate I made with my dad. Thanks, Luke -

That is exactly what I thought when I saw this post

-

Post drill for sale could do with some advice

Zeroclick replied to Zeroclick's topic in Drills, Post drills, Mag drills, etc

Thanks Smoggy, Based on that I will hold off and keep an eye out for one that will be more adaptable. -

Post drill for sale could do with some advice

Zeroclick replied to Zeroclick's topic in Drills, Post drills, Mag drills, etc

Hi Smoggy, Thanks for this, this one is up for £49 which seemed like reasonable price but then if it is no better than those supermarket ones I might be just as well buying one of them or waiting and saving up. What would be the best low end speed to look for as I thought the 210 speed would be slow enough, to be fair I am hoping to buy one that I can grow into and that can cover a wide range of jobs without burning out. -

Post drill for sale could do with some advice

Zeroclick replied to Zeroclick's topic in Drills, Post drills, Mag drills, etc

I was hoping to get an opinion on how suitable this would be for my purposes, as I have seen others for sale but when going through with people I have been told they would be really suitable for the purpose I wanted. But I am unsure what that was based on so don't really know what I am looking for in the manual to get a true idea of how much use this would be for me. Thanks, Luke -

Post drill for sale could do with some advice

Zeroclick replied to Zeroclick's topic in Drills, Post drills, Mag drills, etc

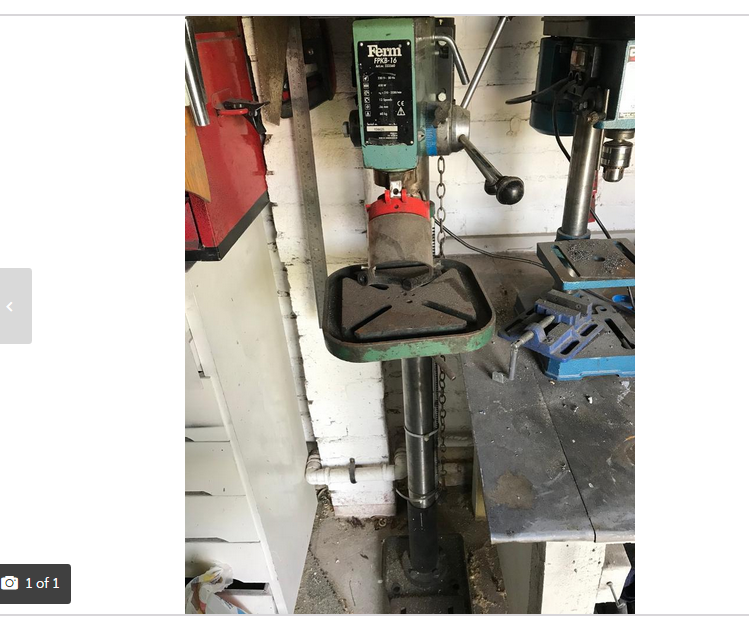

Hi All, Any advice would be greatly appreciated on the spec of the pillar drill, I have attached a pdf to the owners manual and a scrrenshot of the Pillar drill that is for sale. Off site link removed again, next time you pay for it advertising is not free -

Post drill for sale could do with some advice

Zeroclick replied to Zeroclick's topic in Drills, Post drills, Mag drills, etc

Sorry the link I posted was to the pdf manufacturers manual for the model of drill that was in the picture. Thats why i did a screen shot from the sales site to get an opinion on the condition and then posted a link to the specs seperately. -

Hi All, So I have seen this drill up for sale and from the specs I have seen on the attached it looks pretty good. I just wanted to get a couple of opinions on whether this would be a good metal drill. I wouldn't be working anything to heavy maybe 10mm thick at the most and certainly nothing over 12mm diameter. I did notice some damage to the base in the picture but I should be able to put a steel wedge under to balance it. Mod note: the commercial link has been removed per the IFI Terms of Service. If you wish for members to comment on the suitability of this drill, please post the manufacturer, specs, etc in a comment below.

-

What did you do in the shop today?

Zeroclick replied to Mark Ling's topic in Blacksmithing, General Discussion

I didn't measure it with a tape I used the between my knuckle and wrist method and sat it about mid way. I am 5'11" as well my dad is a bit taller but it was more his foot placement he stood far away and then leaned in. Where as i tried to get him to tuck into the heel of the anvil. But I will give it a measure to double check it. -

What did you do in the shop today?

Zeroclick replied to Mark Ling's topic in Blacksmithing, General Discussion

I will he did really well he had a stroke about 6 months ago, so was really happy with what he managed. That tire hammer looks really nice, I have heard mixed reviews on them how have you found yours. Well it is interesting but he told me he had done blacksmithing before in the 70s when he was doing his apprenticeship. He got really into it and couldn't stop smiling by the time we were finished. -

What did you do in the shop today?

Zeroclick replied to Mark Ling's topic in Blacksmithing, General Discussion

So not today but on Saturday my Dad came to visit and helped me by striking for the handle of my bolster plate. It is 65mm by 14mm, I've drilled in a 6mm, 8mm and 10mm and then will be punching and drifting a 12 to 16 mm. Then he had a go at making a leaf key fob, was a really fun day. I did tell him to stand straighter, but who is a son to tell his father -

I used mild and it is holding up ok but then I made it quite short and a bit thicker. I have used it a fair bit and had no problems, but I agree with JustAnotherViking, if you want a finer cork screw use a higher carbon steel.

-

I do like the idea of having a dimmable section around the forge, I used to love working in the dim light of my old shed when you really see what you are working on.

-

Ahh I didn't find diffusers but I found 5m length of waterproof LEDS with cables attached to be wired into a transformer. 5m waterproof LED £6.99 with free delivery driver transformer is £7.99 for 24W or £11.99 for 60W so I could power 3 lengths off one. With this setup I can use the exisiting wiring for the two light bulbs, it will just allow me to follow the beams easier and stop them getting in the way I did consider running them along the lower edge due the low profile. To be honest I had never really considered them until I saw them in this video.

-

I do agree that the tubes do have a lot of advantages but at 5 times the price they are just really steep. I may have a look at how I might position it all. I do know what you mean about the diffusers it do help with the spread of the light. I mean interms of resiliance I don't really see to much between the them the strips are rubber coated and sealed making them resiliant to water and dust to the same degree if not more then the tubes. Also for wiring them in you can just get the transformers and wire them into the existing lighting with no problems.

-

I did look at the strip lights but was a bit put off by the price, I was thinking of using the style below as they are cheap and will reduce the amount of head room I will lose as my shop is quite low. I am hoping to help my eyes a bit as they aren't the best already I am already at glass bottle glasses level. I do like the idea of some really focused points of light in the key areas, I was thinking of getting LED reading lights as they tend to have the really mobile necks to get accurate lighting where I need it. Cheers, Luke

-

What did you do in the shop today?

Zeroclick replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you it was a lot of fun and a real learning experience. I wish I had got my initial cut a bit more even. And thanks again for the videos wouldnt have known where to even start without it. -

What did you do in the shop today?

Zeroclick replied to Mark Ling's topic in Blacksmithing, General Discussion

So today I made a little camp fire set that a friend asked for. Then had a bit of a practice at one of the none welded rings JLP showed on a video. I didn't have any 2 inch material so used 1 inch just for a bit of practice. -

Show me your blacksmith pets

Zeroclick replied to Glenn's topic in Blacksmithing, General Discussion

This is Ronnie he is 4 a cross between a labrador and a patterdale terrier, always full of energy and a great help in the shop. -

One of these bottles can also be useful for controlled quenching, I use it mostly for cooling reverse twists as I dont have a torch at the moment.

-

So my idea was to run the LED strips down either side of the beam that runs the length of the building, then run a shorter strip above the workbench area. Then also based on the advice now add some more direct lighting to really flood that area as it is quite a dark zone. Thanks, Luke

-

I thought perhaps I could get a desk style lamp with a swivel head so I can look things over from different angles this could be over my workbench . I will try to get some photos of the workshop tonight to show you what I had in mind, and see what you guys all think.

-

ThomasPowers That does make a lot of sense sadly my roof is no where near that high, what I may do is use the LED strips to light the shop in a general sense and then after working add LED lamps to the areas I notice need that more focused light. Glenn I did not know that about the different kinds of film, one of the strips I looked at was 6000K so would sit them nicely in that daylight range.