Shaggy

Members-

Posts

7 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Escondido California

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

As an update, I've shelved the plans for the forge at the moment because I was given a portable farriers forge. It's dimensions are as follows, 12"x 6"x 6" and has no lining in it.

- 10 replies

-

- knife making

- forge

-

(and 1 more)

Tagged with:

-

As you may have seen a past thread I start I was asking about a forge. In this thread I'm asking about economical tools and machines needed to make knifes. From your experience as knife makers, what tools did you guys start your craft using and what will work best for a beginner knife maker with some past experience? Also to mention I don't have space in my workshop for any bulky equipment. -Jason Mod edit: Do not post other people blades.....

-

I know with the knives I've made I wasn't able to make them on the first try. The top knife took me 6 billet before I got the last one right. They were either too weighty to the front end, didn't have a appealing profile, or had an issue in the quench (cracking, warping, or not heated to the right temperature to harden the metal) I'm clinically diagnosed as OCD and I'm really picky on how things I make are supposed to look.

- 10 replies

-

- knife making

- forge

-

(and 1 more)

Tagged with:

-

Thanks for the compliment on my knives but when you get a close look at them you can tell there are flaws. On the bottom one the fuller isn't even with the mirror on the other side. I'm actually working right now on the current design tweaking the dimensions of it to make it a smaller forge with only a single burner

- 10 replies

-

- knife making

- forge

-

(and 1 more)

Tagged with:

-

I have had some experience using a forge before, my uncle is a knife maker in duschene Utah and he taught me how to move steel on an Anvil for 6 months when he lived down here, I was 8 turning 9 when he taught me and I made 3 knives under his supervision(pictured below) all were made from blanks cut from a saw blade from an abandoned saw mill in Utah. As far as it goes I want a forge I can make Damascus steel in. I am currently enrolled in a coal forge blacksmithing class 2 towns over from where I live, currently were making tools for the hardy holes and I'm going to ask the teacher if I can make a fuller device for home use. I'll take your advice and read through the gas forge section and make alterations to my current design to make it a smaller forge. As far as a burner goes I'm not even sure where to start. even with the things I've been reading I'm confused with how to calculate how many cf the burner has to be rated for to bring the forge to the proper working temperature, if you have any knowledge on that I'm more than willing to carry a conversation with you via email to gain a better understanding. My email is on my profile and the offer is open at any time for anyone who would like to bestow knowledge on me. -Jason

- 10 replies

-

- knife making

- forge

-

(and 1 more)

Tagged with:

-

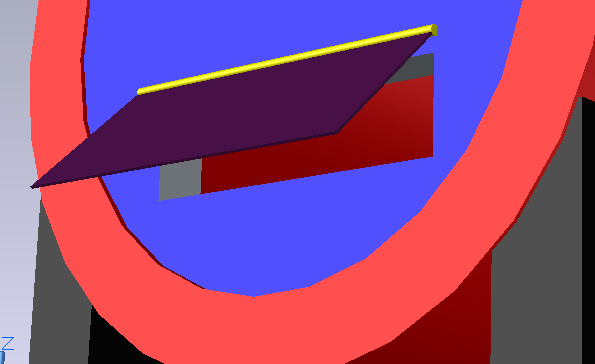

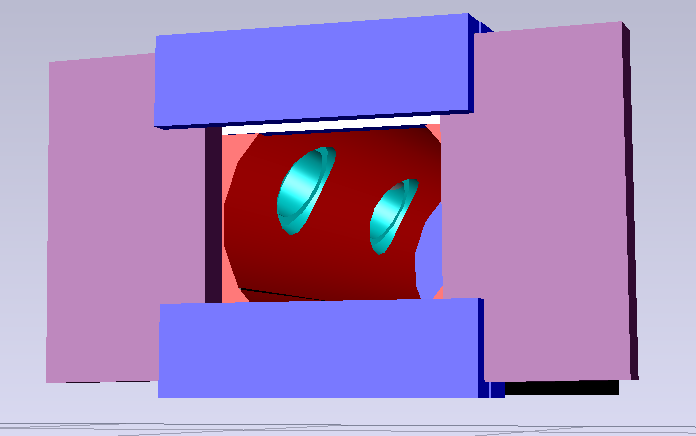

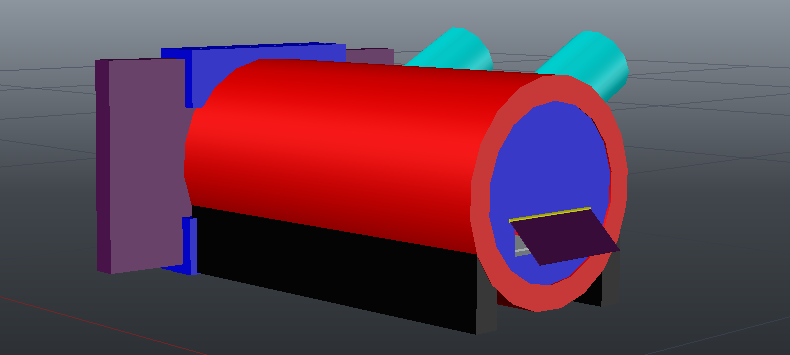

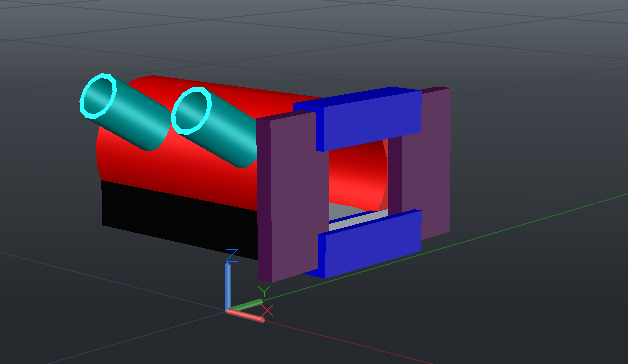

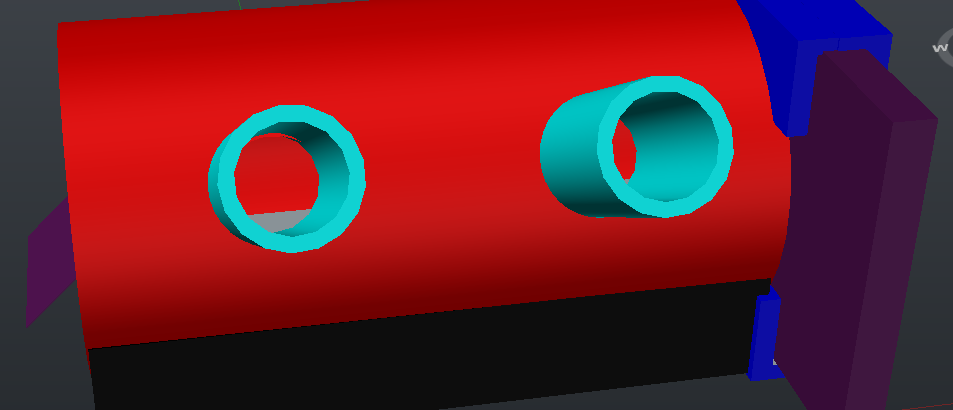

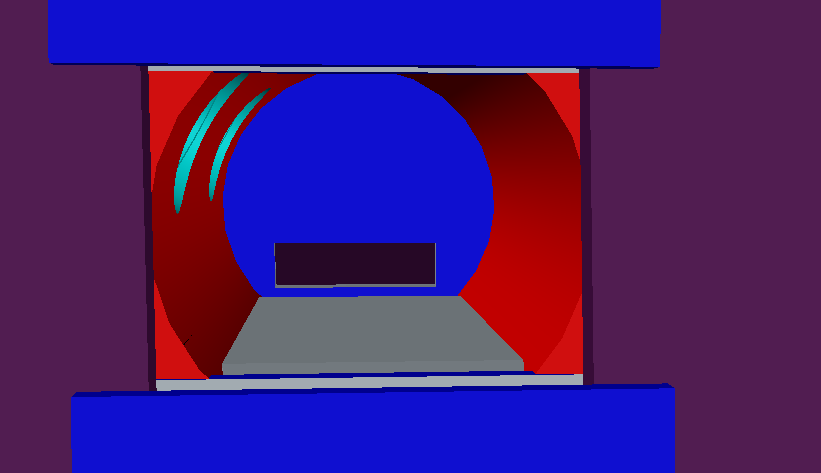

after recently been laid off at the machine shop by work that I've decided to take up an interest that's fascinating me since I was a child. Below I have 3-D renderings of the forge I designed this is based after the forge that my great uncle used. It's going to be made from a steel cyclinder that is 21" long, a 1/4" thick, and has a 10" diameter. It has an end that is blocked off with a rectangular hole of an undetermined size that will be able to be covered by a hinged door. The main reason I added this feature is so there isn't a jet of fire being blown out of the open end of the forge. I also equipped the forge with slots that I can put in refractive sheet bricks to be able to close the forge til it comes to working temperatures. I'll be lining it with 2" KAO wool using ITC-100 to make it a more efficient forge. It's going to be a dual burning forge with a valve that can limit it to a single if desired.On the bottom I'm going to make a flat surface using a refractive "clay" so the work piece isn't resting on the wool. I would like to hear your thoughts, opinions, things you would change, and things that you would do to make it better. If you like the design feel free to use the renderings I've attached to make your own. -Jason

- 10 replies

-

- knife making

- forge

-

(and 1 more)

Tagged with: