-

Posts

166 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Gorō

-

I'm thinking of fixing an anvil as well. Here are some pictures, we should create a thread and sticky it purely for the purpose of fixing anvils because I can't find a lot of information on the internet about it.

-

Cheers Stan That probably explains why I'm so crook.... I've left the anvil in Newcastle will give it a nice clean when I have time. I'm thinking of getting a oxy torch to pre heat and arc weld and smooth the edges on the face abit aswell. I might as well...

- 27 replies

-

- anvil

- london pattern

-

(and 1 more)

Tagged with:

-

Ok thanks. Wanted a drawknife/sen for rough filing work. Thanks

-

When using a draw knife is it more of pulling motion or pushing motion? is 5160 ok for a drawknife/sen? I've always wanted to use one instead of the linisher/grinder. Cheers

-

G"day found this vise on eBay for $50. What do you guys think? I don't have a vise because I'm still setting up my shop. I was wondering if this vise would be ok to use or am I better off just spending abit more on something brand new???

-

Any idea on what kind of anvil it is? I will have to weigh it again. But the seller has advised me it's 115-120kg and it was still quite heavy even for a 2 man job I would believe. cheers.

- 27 replies

-

- anvil

- london pattern

-

(and 1 more)

Tagged with:

-

I've been told and read/watched online that welding on the face of the anvil makes it soft and can crack....some people have advised that I pre heat with oxy torch

- 27 replies

-

- anvil

- london pattern

-

(and 1 more)

Tagged with:

-

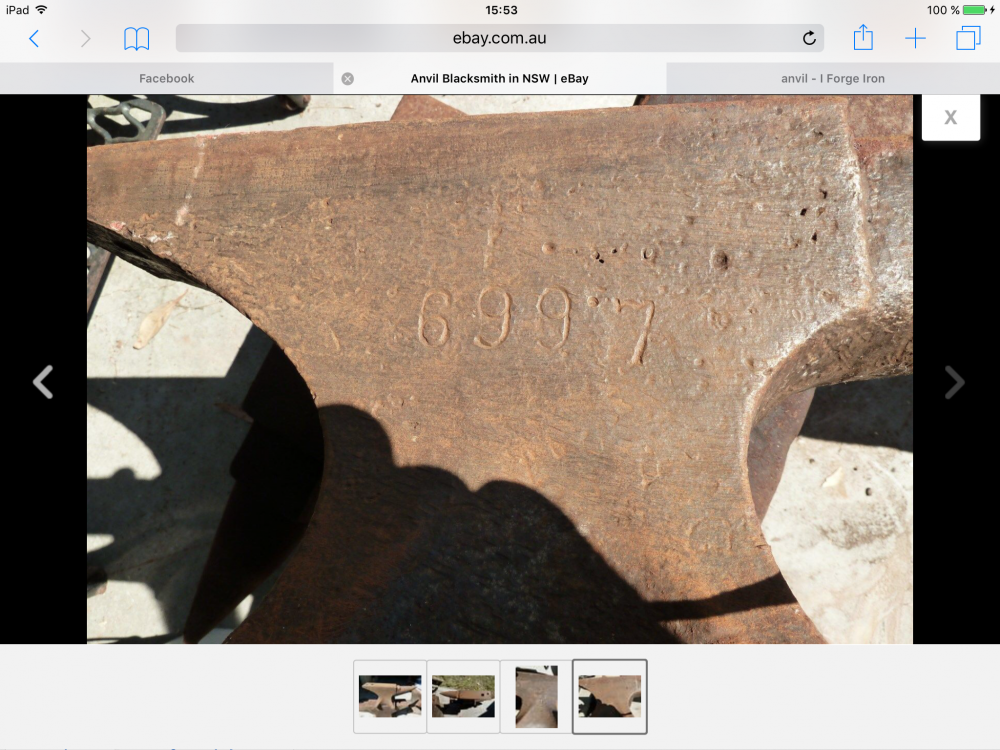

Size and weight. There was a John Brooks which was one inch longer same weight and everything but when I did the rebound test....nothing.... got a hammer and hit it softly to hear if it rings but only times I could hear the ring was near the hardy hole. I'm thinking of cleaning it up abit and welding the edges to fill the cracks and dents

- 27 replies

-

- anvil

- london pattern

-

(and 1 more)

Tagged with:

-

I was thinking of fixing up the face on my anvil because there's dents and cracks in the face. I've been talked out of it because if I'm unlucky I might "crack" the anvil.

-

What kind of tools did you use for punching the eye?

-

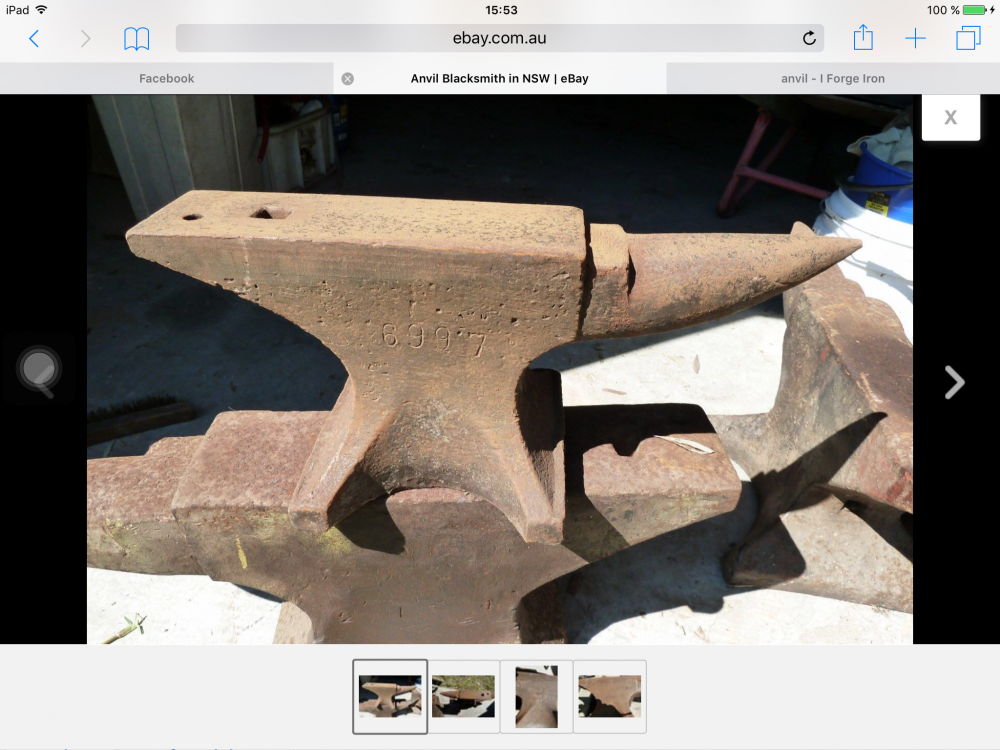

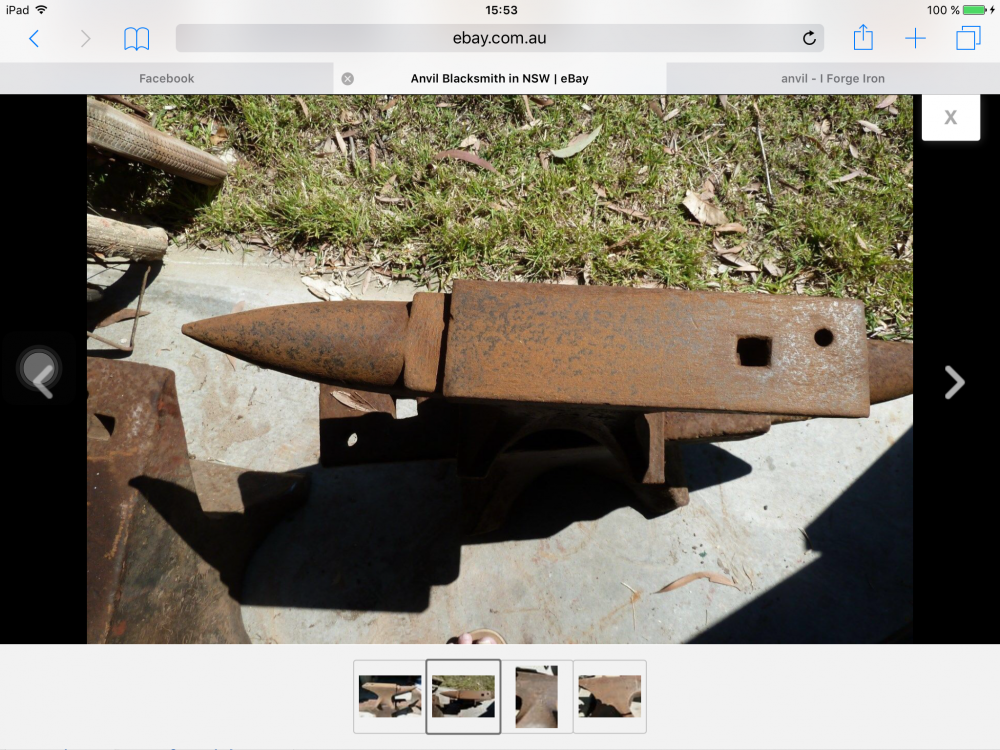

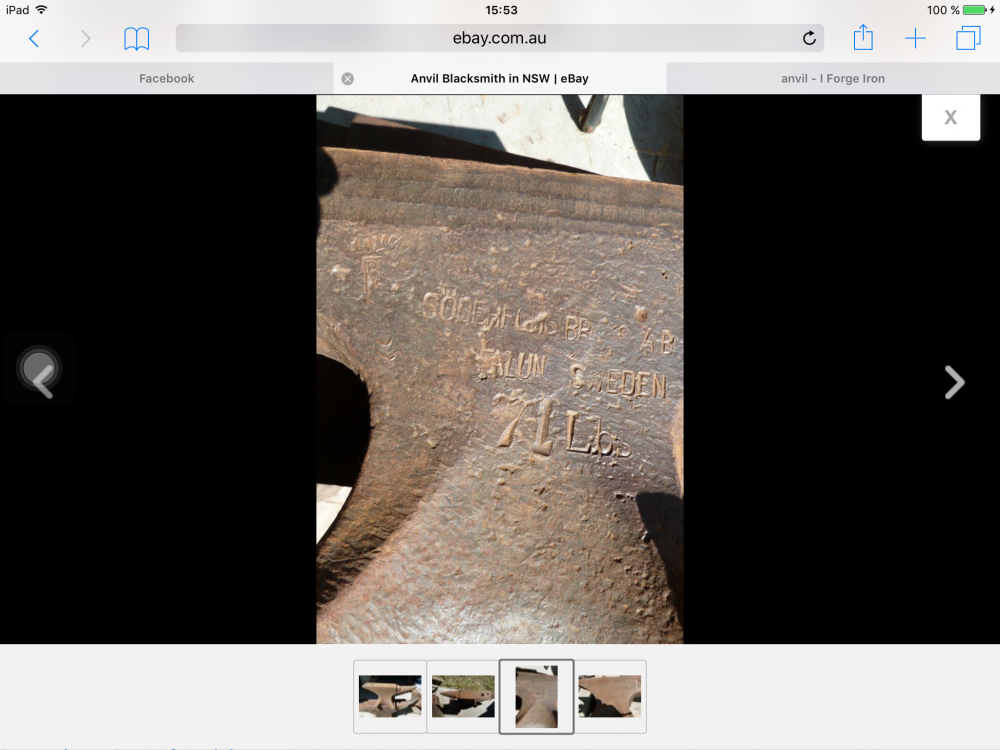

Just picked this up today, paid a good price for this. anyone here know what brand of anvil is this?? Thanks

-

Hey there fellas just picked up this gem this weekend. I saw a Soderfers and John Brooks anvil but I liked this one better but I've got no idea what anvil maker branding is it. It says 2 1 4 which is 256lbs Im guessing it's a John Brooks. I know it's not a Peter Wright or Soderfers Cheers

- 27 replies

-

- anvil

- london pattern

-

(and 1 more)

Tagged with:

-

Ended up getting something heavier. It's not a soderfers. Anvil face has cracks on the edges....but there was another anvil with no hardened face which was the same weight so I went with the one with the crack on the edges.

-

Will do, picking this gem up this Monday. It's about 3-4 hours away from me unfortunately. Just a question about anvils is it true that if the anvil has more mass and weight it's easier to move steel when hammering? This is picture of a tanto I've forged on a friends soderfers anvil. Maybe it's my hammer technique but I have to use more heats whilst I see people on YouTube use less heats

-

I'm planning to pick up the anvil this weekend hopefully or this Monday. it was posted on eBay for $600aud but I've bargained with the fellow and have come to an agreement in regards to the price of the anvil.

-

Since anvils are so hard to find in Australia. How does this look? I think I would most be making blades,hammers and other kind of work that requires a striker. Here are some pictures. What do you fellas think????

-

I'm kinda sad when I see everyone post pics of their anvil.

- 18 replies

-

- hammers

- blacksmith

-

(and 5 more)

Tagged with:

-

About those Brent Bailey hammers, which one of the two would you prefer? The Mark Aspery modified or the cross pein??

- 18 replies

-

- hammers

- blacksmith

-

(and 5 more)

Tagged with:

-

I can only see two visas in the pic, how did you hold up the other pieces of rebar?

-

Saw your post about the hammer rack, you have a generous amount of hammers! Thank you! Lyle Wynn made the rounding hammer. The dog head hammer was made by Glen from GS tongs!

- 18 replies

-

- hammers

- blacksmith

-

(and 5 more)

Tagged with:

-

G"day from Australia Just curious what kind of hammers everybody has in their blacksmith forge! Im still new to this but here are my hammers.

- 18 replies

-

- hammers

- blacksmith

-

(and 5 more)

Tagged with:

-

Ok thanks

-

Thank you for the reply Joe I've watched your videos on YouTube. In fact what got me on to peddinghaus is because of the youtube. I'm sure Daniel lea on YouTube uses a peddinghaus..... Any idea how I can source a peddinghaus? I'm from down under and we don't have much variety in quality anvils unfortunately I was even considering buying a peddinghaus style anvil from the Czech Republic but once I heard they didn't accept PayPal I talked myself out of it, tough times.....haha