TheAngryScrapsmith

-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by TheAngryScrapsmith

-

-

1 minute ago, DSW said:

Swinging buy and talking "shop" with them and maybe bringing some cold ones or a box of donuts could get you access to all sorts of tools and equipment as well as scrap and materials.

A very good idea indeed. I have looked into this a little, but with the military drawdown under Obama and the budgets being slashed those underused facilities have been getting closed up pretty quickly. We do have a pretty comprehensive garage on post called Sprockets, but it is always packed.

-

I have about 100ft of wrecker cable from an Army HEMTT Wrecker. It had been partially unspooled and spilled all over my garage floor, so today I decided to cut it up into pieces and make "straws" out of it. I also made a spool of it (I would guess 25 or so feet) to use for bartering sometime. I cut some of the straws into what I thought would be a good knife length and some at about 2.5 feet for... I dunno yet.

Attached is the video of the spark test and a pic of my little bartering spool!

(Sorry, this is unrelated to... well... anything) -

1 hour ago, littleblacksmith said:

what's the second store that your talking about?

http://www.texasfarriersupply.com/index.php

It is about 2 hours north of me. Though, if the pricing on the website is right.... It looks like I can get 500lbs of coal for $112 plus the cost of gas both ways! -

11 minutes ago, littleblacksmith said:

Littleblacksmith

Your profile says College Station, TX. Is that the same College Station east of Austin? There is a place in Austin called Centaur Forge. I wonder if you have had any experience with them? I'm in the unfortunate position of basically being 2 hours (ish) north or south of my only 2 smithing supply stores...

-

Okay, one more ask. I dug around the site and couldn't find this info per se.

Where do you gents recommend I go to buy good steel (mild or otherwise) for forging structural parts of my shop?

There is nowhere local for me to buy coal (unfortunately) so I am stuck buying it online.... Any recommendations? -

-

Spark tested some of my steel today. It appears (to my untrained eye) that most of what I have is high carbon, but the piece from the barbell was indeed low carbon

It was the only piece of steel I tested that appeared noticeably different. I took a few pics for show and tell, but I don't want to go spamming them if they are unwanted.

It was the only piece of steel I tested that appeared noticeably different. I took a few pics for show and tell, but I don't want to go spamming them if they are unwanted.

-

Let me say thanks to all the gents here who offered up there wisdom! This forum is A LOT more active than I had imagined and I am very grateful for it! I joined a number of smithing pages on FB, but it seems most of them are just grinders hocking their wares. I am working on the plate fence and then the table today. I haven't found any good local clay though, so I'm still searching for that.....

Again, thank you gents so much. I look forward to someday being able to contribute to the next new guy! -

3 minutes ago, SLAG said:

Let us not mince words. Chrome and especially zinc are POISONOUS when heated. The fumes can injure your health and in some cases kill you. A friend of mine died burning the zinc off of galvanized metal 11 years ago. Read up, be cautious, and stay healthy.

SLAG.

Oh wow. Thanks for the heads up. I knew galvanized was bad, but I made the mistake of assuming the chrome plate would just be hammered into the steel and maybe slake off as slag. I will definitely check the piston rods for chrome plating.

29 minutes ago, Charles R. Stevens said:Any heavy metal coating is bad. The old adige is "if it rusts" tho stainless is an exception, as is titanium.

Side blast will be happy with coal as well, but as we have a bottom blast to deal with, let's see, what we can do, re shaping the bowl is a good idea, but the clay will vitrify and the clinker will stick to it like glue, sand and ash will help with that, think Adobe with ash added, again a 8" bowl is probably plenty wide , as we can only work about 6" by hand. If the bowl proves to deep consider a bullet grate (2" pipe cap with a 3/4" hole drilled in the center) a table is really convenient, especially for keeping hot coals from falling when you are moving stock in and out, so that 1/8" might be better used making a 24-30" table. That way you can better manage your fire, and coal needs to be herded like cats...

And so a table and some fencing are on the menu for tomorrow. I think I'll have enough material. If not I'll have to find some more scrap... Hard to do around "The Hood" as scrappers are ravenous around here.

-

Chrome plated = bad? Crap!

-

I'm using Bituminous coal for the forge, I only used the charcoal to test my welds and fire pot for strength.

5 hours ago, Glenn said:

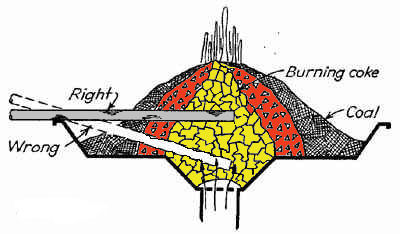

You need a fire deep enough to have a fire ball about the size of a melon. The metal should go in about 1/2 to 2/3 up into the fire ball as shown in the drawing.

I think my problem might lay in this diagram here. I don't think my forge is going to be big enough to get a melon sized ball of coke for working. The steel bars are 1- 1.5" thick and are (I'm assuming) very hard, high carbon steels. Besides the barbell (which may be low carbon) I have 3 hydraulic piston rods and 3 HMMWV axles. So, I guess I will build my fence up a bit tomorrow and try getting a bigger ball of coke. Should I be using smaller coal lumps due to the size of my fire pot? I saw mention of "rice" coal. I thought the smallest used for forging was pea...

-

I burned a full bag of charcoal from start to finish and beat on my welds when it was fully engulfed. I wanted to make sure my welds wouldn't fail once I put coal in there and started work. (I had a previous incident where a leg weld broke off when I brutishly moved my forge around). I am using nut-sized bituminous for actual hot work though

-

Thanks for the advice gents. The fence is something I have toyed with the notion of doing. I have about 2.5 feet of 1/8" plate steel left and may use it for the fence, though I also considered welding it next to the pot for a coal shelf/table to store up extra fuel. I hadn't considered using the clay to bowl out the drum, though that seems obvious now that you say it. Is there any specific kind of clay that won't break apart if I jab it with a hot piece of steel? If I'm around Fort Bliss I'll be sure to give a shout out!

Daswulf, I've attached a pic of the forge top-down view. The grate seen in the pic is what I use to filter out clinkers. The vent fan is 50CFM going from a 4" tube to a 1 3/4" pipe. I ground it out as much as I could without messing up the drum. Coincidence I even have this pic, one of my Soldiers asked me for it a while back. Lucky me! -

I'm at Fort Hood, TX. I'm a Soldier, presently on a 24 hour shift. I'll upload the pics I have from working the forge Friday. I just joined this forum today. I have only been at this for a few days now, it took me a while to assemble all the scrap for my forge and build out my anvil pedestal, etc. It isn't easy when you're working 12-14hr shifts everyday for 2.5 months, haha.

The metal I'm working with is a piece of cut barbell. -

I have built a brake drum coal forge and have started trying to work a piece of steel from an old barbell into a spoon chisel for wood carving. I know it's probably too complicated a job for a beginner, but I'm a "dive right in" kind of guy. The problem I have is that the steel doesn't seem to stay very hot and workable for very long. When I pull the steel out of the coal it is red hot, but not a glowing bright white or yellow that I seem to see when people are working mild steel, and it cools pretty rapidly making my work that much harder. Is there anyway I could tell if I was heating it too little or why it won't stay workably hot for very long?

Any feedback or help is greatly appreciated! I'm eager to get into this and make some cool stuff!

Beginner - And a bit confused about what I've got...

in Blacksmithing, General Discussion

Posted

North Fort Hood is attached and belongs to the Texas National Guard, but is routinely used as a normal part of the main cantonment. I've been here for 4 years, there are motorpools everywhere and there is definitely Air CAV haha. Every Unit has one (typically organized by Battalion or Brigade depending on unit structure and MTOE). I get most of my scrap from the dumpsters in those very motorpools. Sadly, Soldiers do almost none of their own machining or manufacture anymore. Those tasks have been outsourced to civilian FSRs (Field Service Representatives) which leaves most Soldiers only capable of taking parts off and putting new ones in place. The Navy on the other hand (I was Navy prior for 6.5 years) still teaches many repair and fabrication techniques. I was a Submarine Sonar Tech and was schooled in electronic repair and learned hydraulic repair on the side in the fleet.

I don't want to come across as argumentative, so I don't want this read in that tone. I am always on the lookout for an opportunity to learn a new skill or technique (of any productive kind honestly). I am also fairly notorious around CAV for my ability to BS with someone and get a few favors out of the conversation and a new resource for "item/service X." To whit, if any of you gents are ever nearby and need an assist or maybe some scrap steel I have laying in the garage, lemme know.