-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ubba Bloodaxe

-

A mistake. I ordered this 96 lbs ASO. It was hollow. I filled with concrete. It's ok for tinkering around. I'm just going to bite the bullet and drop some serious money on a nice anvil. I'm seeing the uselessness of having zero rebound. Trying to hammer out my tang and it wouldn't compress evenly. But, it helps me get my arm into hammering shape. Lol.

-

Yes, sir. My grinder gets delivered today. This knife is basically an experiment. Just getting my feet wet. Seeing how the steel moves, how the Flux reacts, cooling rates, forge economy, etc. I appreciate the feedback. I'm not too optimistic that this will become a completed knife but, just an opportunity to gain a bit of knowledge. My next blade will come with a bit more demand for perfection and the next..... Can't wait to get it ground and cleaned. Who knows, may actually have some usability.

-

I believe so. It's a sling for crane rigging. I figured it would be a good test.

-

Hello smiths, Today I finally got all my ducks in a row, lit a fire, and heated some iron. I was going to make a coal rake and a poker. But, I'm a bit too anxious to see how I do with a blade. To make my first attempt even harder, I decided to do a cable Damascus blade. Lol. Do the toughest first, then the rest will be easy, huh?? I'm sure the weld wasn't perfect and I will probably have splitting of the layers. But, it's a learning experience. I need to clean up the profile and level out the blade (I was tapped out by this point) but, I'm very satisfied with my first attempt. Utility sized, broken back seax.

-

I took your challenge and I think I completed it as simple as I could. I quit trying to develop new ways and stuck with proven technology. Thanks again for setting me back on the right path.

-

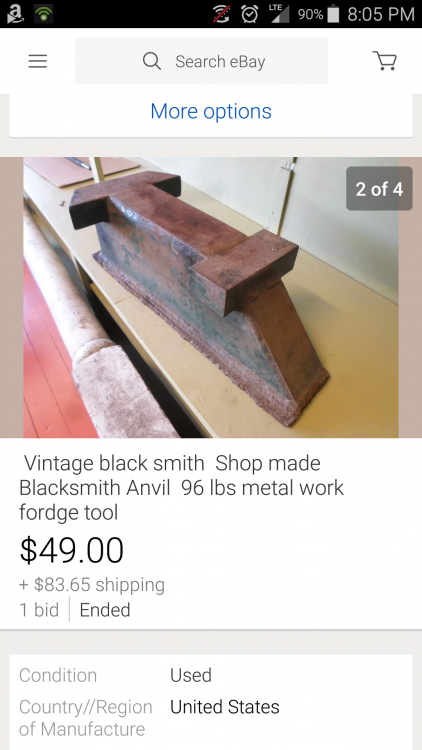

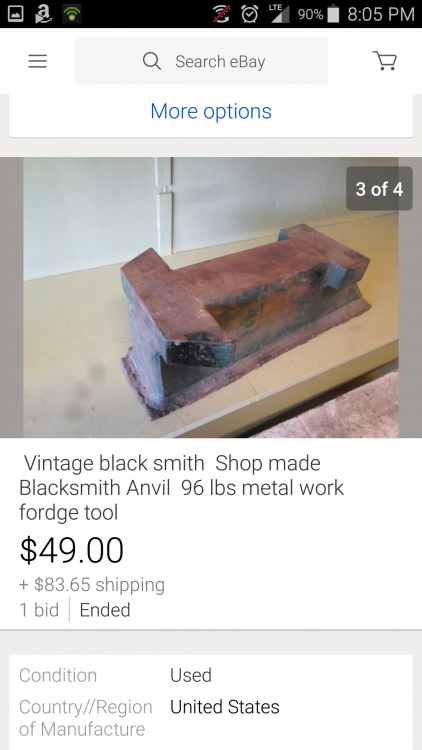

Considering buying???

Ubba Bloodaxe replied to Ubba Bloodaxe's topic in TPAAAT - Applied Anvil Acquisition Technique

Keeping my fingers crossed. I think it's steel. Is there a test I can do to truly determine the makeup and quality? -

Considering buying???

Ubba Bloodaxe replied to Ubba Bloodaxe's topic in TPAAAT - Applied Anvil Acquisition Technique

OK, so I was looking for anvils and found a huge hunk of iron. 90+ pounds long and wide...... $50. I think it will get me hammering. -

Considering buying???

Ubba Bloodaxe replied to Ubba Bloodaxe's topic in TPAAAT - Applied Anvil Acquisition Technique

Very nice. -

Considering buying???

Ubba Bloodaxe replied to Ubba Bloodaxe's topic in TPAAAT - Applied Anvil Acquisition Technique

So turning the track on end will reduce the working area but increase the mass under the hammer strike? -

Considering buying???

Ubba Bloodaxe replied to Ubba Bloodaxe's topic in TPAAAT - Applied Anvil Acquisition Technique

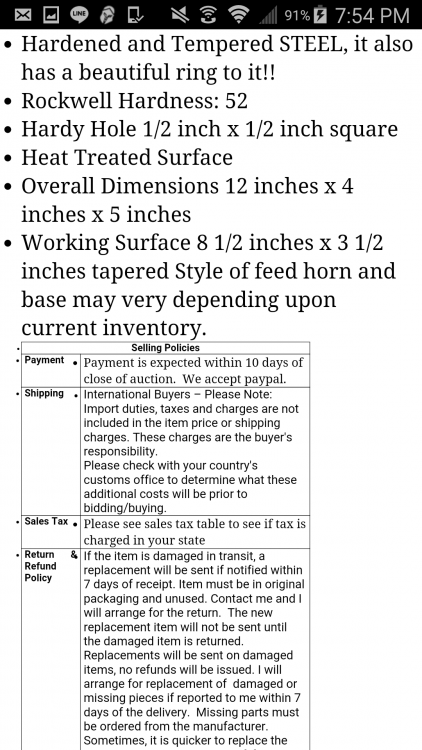

I really just want to do knifes. Probably the largest would be a Scandinavian seax. Maybe 12 - 14" -

Considering buying???

Ubba Bloodaxe replied to Ubba Bloodaxe's topic in TPAAAT - Applied Anvil Acquisition Technique

At least there's that. Lol. I think I've decided to just go with a nice long piece of railroad track. Fairly cheap and it will start me hammering. I have a big job coming up and overtime will be used for an actual anvil. I found a Turkish farrier's anvil for $350. Free shipping on top of that. -

Considering buying???

Ubba Bloodaxe replied to Ubba Bloodaxe's topic in TPAAAT - Applied Anvil Acquisition Technique

10-4. That's what I needed to know. I knew $50 was too good to be worth it. Thanks -

I found this online and would like some feedback before I send some money. Would this be a good starter anvil?

-

Excellent way to put it...... Challenge accepted.

-

I was thinking about building a wall with the fire bricks. I've been looking for local groups. If I was into crawfish farming I'd have 20 to attend.

-

Guilty. I over complicate just about everything. As Frosty pointed out, I'm tossing and turning at night redesigning the wheel. Wow.... I kinda scared to see how bad I destroy some innocent steel. Lol

-

Hey, thanks for the input. I was afraid the forge was going to be a bust. I got tired of thinking about it and had to get my hands on something. The clay is mixed with vermiculite and will be covered with 1" fire brick I liberated from the stress reliving pile at work. A couple weeks from now I'm getting a welder and will put together a proper forge with sheet metal and fire brick and a layer of furnace cement. I'm not really good at just reading and saying, oh that's how I'm going to do it.... I like to exhaust time and money with hands on failures. Not by choice though. It's an inability to stay static when the bug hits. I feel 100% move advanced than I did yesterday because, I moved forward. Well, backwards really. Good stories to share with my future apprentice.

-

I'm replacing it before I put heat to the forge. It was an impulse buy. I have a box full of impulse buys so far. Another reason it's already an expensive hobby. Lol

-

Lol no.... Even worse... Vent flashing. Very thin like dryer vent. I'm strongly reconsidering... I'm working on getting some black iron but the vent flashing is keeping the clay formed for now.

-

Hello all, I'm James. I'm new here and to the art of manipulating steel with heat and muscle . I've spent the last 2 - 2 1/2 years reading, watching, and listening to anything and everything about throwing the hammer. I finally alloted sone time and money to developing a new addiction. I'm starting from scratch and, I'd like to say cheap. But, not so cheap when I have to buy even the simplest tool to build my forge and cut iron, grind, file, measure, throw away failed projects, and sit down exhausted and weep. But, as of one hour ago I have my forge fire clayed and air supply pipe in place. I feel like I have a working elementary understanding of the basics due to this forum. I've been lurking and reading all of the shared knowledge posted here. I thank you all for sharing. I look forward to learning from your mistakes and your victories. I am a heat treater by trade and have access to tones of heating equipment..... As long as the boss doesn't find out. . Shhhhh. If you read this and want to warn me to stop before I start...... I'm pretty hard headed and overly excited to try my hand at this. My goal is pattern welding... Not Damascus but, Anglo saxon / Scandinavian pattern welding. Uthbert will be my goal. I'm excited to be here. Below is a couple pics of my new / First forge. Be gentle, I know I'll be ordering a new, better one soon. Just had to be moving forward.