-

Posts

123 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by fleur de lis

-

Finally got me a hammer

fleur de lis replied to fleur de lis's topic in Power Hammers, Treadle Hammers, Olivers

Steel military surplus shipping pallet. They're rather solid. My surface grinder is sitting on one & its somewhere around 4000 pounds (until the new shop gets a new roof). Picked up a couple years ago for 10 bucks a pop. Wish I'd have bought more. -

Finally got me a hammer

fleur de lis replied to fleur de lis's topic in Power Hammers, Treadle Hammers, Olivers

When I was a kid, I'd have called this ghetto. Now I call it using what ya got / blacksmith ingenuity. My A frame wasnt tall enough to get it off the trailer. So it was a tree, 2 lifting straps, 1 chain, and a 79 Bronco. Set it on a steel pallet & drug it to my shed with the 8n. Then my wonderful wife & myself man handled it to its home. Ran it some. Enough to draw out a 7/8" x 4" round bar to 8" in a couple minutes. I'm not gonna know what to do with all the extra time...... Best $3000 I've spent in a long time. -

Finally got me a hammer

fleur de lis replied to fleur de lis's topic in Power Hammers, Treadle Hammers, Olivers

No the the bottom die tool holder thingy ain't much of a issue. It works, so I'm gonna use it until I find something better. It'll be bolted to the floor with a bunch of 3/8" anchor bolts through the cement floor of the current shed. I may do something different once the bigger shop is done. But I doubt it. The crank has almost no discernible slop in any direction. If I hadn't spent years dealing with the fit up of machined parts at work, I'd probably not have noticed it. -

Finally got me a hammer

fleur de lis replied to fleur de lis's topic in Power Hammers, Treadle Hammers, Olivers

I wasn't giving it much foot. As it was still strapped to the back of the truck & it were a whole lot of bouncy running any faster. I couldn't hold my phone stable enough to film it. -

Been wanting one for a good long time, finally got the chance to get one. Found a 25 Mayer Brothers local to me in good condition in a working shop. Not much slop in any of the parts, bunch of shims in the caps for the babbits yet. Running on a 110v motor, which is a big plus for me as I'm almost out of 220v lines & I've still got to get the surface grinder wired in. Not to sure of the home made bottom die & holder thingy, but it'll have to suffice for now. Said it's been rebuilt when he got it. Got to run it a bit & look it over before taking the plunge. For once in my life, I didnt even haggle (I've argued the price of ice with an eskimo. In Fairbanks of all places). I don't see many power hammers come up for around here & when they do, they're almost always 5k & up. I'm way to cheap for that. Tips & pointers are appreciated. 20190425_200649.mp4

-

Wood staining advice needed.

fleur de lis replied to fleur de lis's topic in Finish and Polish for Knives

Very good point Slag. I do use a two filter full face mask. Preferably of a known name brand. I use a Honeywell right now. I keep different filters for different things. I don't like a that covers multiple things. I feel that those won't do anything well. I don't particularly care for acetone & don't really like having it in my shop, but I do & I do use it. I just try to be careful about using it. -

Wood staining advice needed.

fleur de lis replied to fleur de lis's topic in Finish and Polish for Knives

Kozzy speaks truth. Every word. I just got stupid lucky with this. It's part of a bowl blank I bought about 10 years ago. Was supposed to be birdseye but is just soft maple. So I set it aside and forgot about it until a couple months ago. Fortunately it's not gone punky yet. Professional stabilization would be best, but in a consummate cheap skate. So here's another method. Not a good, but doable one. #10 coffee can filled halfway with minwax wood hardener. Cut that 50% with acetone. Add a dye or stain of color preference. I used a minwax redwood something in this one. Submerge your wood in the can & seal it good. Forget about it for a few weeks to a month. Then remove & let it cure for a few weeks or so. Not fast, but it does work. When you work it, WEAR A MASK!! This stuff can't be good on your lungs. -

Wood staining advice needed.

fleur de lis replied to fleur de lis's topic in Finish and Polish for Knives

Finally got back around to this. To many projects going on. Birdseye maple. Both dyed & natural. The natural is sanded to 500 grit & a couple coats of my BLO / Tung mix. I started with the instructions for the dye & prep. Then I said to heck with it. Mixed up a strong batch of dye in a large Mason jar & dropped the wood in it for a a week. Until the wood was just barely floating still. It's been drying for a few days now & hasn't been sanded or finished in any way yet. The big piece in the middle is some spaltted maple I've been playing with. -

Need some advice on power hammers & presses

fleur de lis replied to fleur de lis's topic in Machinery General Discussions

That's what I was thinking, just wasnt sure. I've done canister by hand to this point. I can keep doing by hand. What do I need to look for when looking at a powerhammer? Condition wise. -

My wife threw me for a loop yesterday. I've got a truck for sale & she's insistent that I spend the money once it sells on a power hammer or a hydraulic press. I'm completely out of my knowledge base on either option, heck I've never even seen either in person. Let alone used one. I've tried researching through the sight, but there's so much info that I'm at a loss of where to start. Most of my work has been leaning towards blades over blacksmithing lately, but I'm still doing the odd hinge or poker or whatnot for folks. Which kind of machine would be better for both bladesmithing & blacksmithing? What do I look for when looking at a potential purchase? Questions to ask? The only odd stuff I make is canister damascus. What's a reasonable price for either? I'm sure there's a lot more I need to think of, but I really don't know what. I've found some 25 Little Giant trip hammer nearish to me for over & under $3k usd. As well as a #25 Kerrihard in the same price range. I found a homemade forge press somewhat local, but it looks very sketchy & they be wanting some serious coin for it. Any advice & pointers is greatly appreciated.

-

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

I only wish that I owned a press of any sort & my minions are too lazy to pick up a hammer, let alone swing it. Someday I will have a bit of land somewhere with a year round gravity fed stream, then I'll build a water wheel trip hammer & maybe a grinding wheel. -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

I'm partial to my old Wagoner & Griswold for plain cast iron. I like the weight & smooth surface. I don't own a "modern" pan for cooking anymore. I'd noticed the number of billets used in the sutton hoo article you posted. Its interesting comparing the differences between the ancient smiths and modern. Technique wise. -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

Thank you. My brain was saying Staub. Which I knew was wrong, but are amazing enameled cast iron cookware. Loves them I say. Of sorts. I think that the folks who planned the roads here, did so in an opium den. -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

Those are called round abouts AROUND here.... -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

This is the one I like. Was done by Manuel Quiroga. I've found several other variations with a slower & a faster twist which all looks really good. The second photo (I forget the smiths name, Salem S something) is closer to what this was originally about. -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

My working theory on this is as thus. There is a secret society out there who is responsible for naming streets and some towns. It doesn't matter where you go in America, every town has the same street names. Is this a coincidence? I think not!! It is a conspiracy to confuse & mislead people!! Must be the road naming department of those eyeball triangle people, who's name I can not remember at this time....... I have wondered how things get named and the progression of languages. I find the transformation of say middle english to modern english to be interesting. -

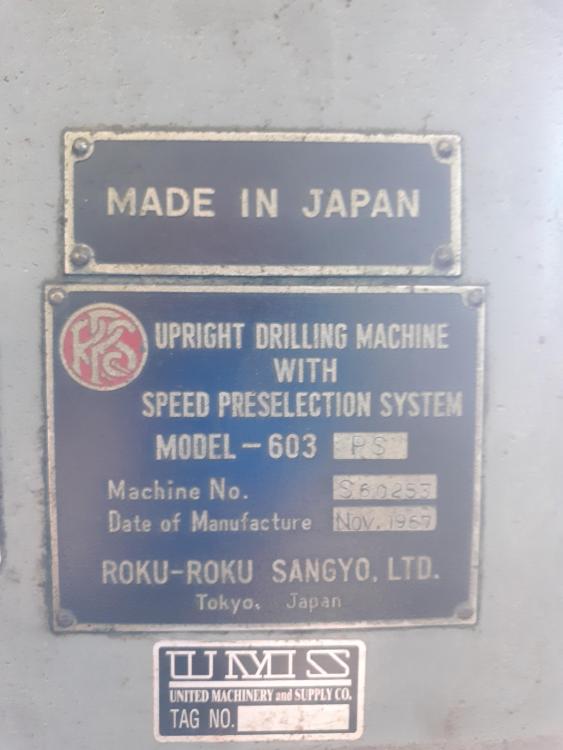

Old equipment isn't so common around here either. Not since the great scrapping about 10 years back. I saw many a good machine head across the scales back then. Scrap prices were just so high. Everything that's turning now are the survivors. These two are maybe 20 miles from the house, so I'm borrowing a smaller truck from work to haul them home. My truck sits a bit high. I must admit that I've a fondness for old Japanese made machine tools. I've always found them to be well designed, well built, & made to last. So I'm very happy to have acquired this one.

-

Latticino is correct. The head is on a cross feed slide. I'm eager to get it home & running. Hopefully Monday

-

scored me a new surface grinder using the Thomas Powers applied anvil acquisition technique, but for a surface grinder. Because I'll I'm tired of fighting the one I've got. Never have gotten it to work right. Anywho. This is a Thompson model B with a 6"x18" mag chuck. The wheel that's on it is new & has some extras. 220v 3ph 3hp motor, so all I'll need for this one is a phase converter or a VFD. It's a lot cleaner in person than the photo. Has some other assorted goodies to round it out. I also got the big drill press in the photo to go with it. Didn't really need it. But who am I to say no. All for the princely sum of $300 usd & I owe him a pocket knife. Small machine shop who's out grown their available space. So the old machines which ain't seeing use needed to go.

-

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

I feel thoroughly stupid now. This idea has never once crossed my mind. -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

I know. Its just wishful thinking. I've got a 5 gallon bucket I've been slowly filling. I'm simply impatient. Frosty, I've no idea if you're pulling my leg or not. -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

My German is very very rusty. Took a few years in high school half a lifetime ago. I do better with Russian these day. I will look into the title though. Despite the political ideology of Germany at that time, the teutonic thoroughness was very prevalent at the time. It should be a very in depth read. I've "started" looking into & researching the migration era, but I would say that I've got real knowledge as yet. Granted I've draw out a langseax I'd like to get to at some point. I'd not thought about carbuizing. I'd very much like to get into bloomery though. Spent a good chunk of winter reading / researching & gathering materials. A good source of local iron has been the hold up. May just end up having to break up old brake drums. I'd much rather find some iron sand or bog iron. I've got to xxxx many interests. I feel like I never get anything accomplished. -

Merovingian pattern question

fleur de lis replied to fleur de lis's topic in Knife making Class General Class Discussion

Mr. Powers that is one of the more interesting reads I've had in a while. Thank you very much. Should be of great help to me. Especially with the pictures. Mr. Sells, thank you. It's a starting point. I've got just enough material on hand without a name on it to give an experiment a go. -

I'm wanting to give this pattern Damascus at try as I really like how it looks. I can't however find much on how to build it up past that it 5-6 multi bar. So my questions are these. Best / good layer count. This I'm willing to play around with a bit. Next, is this a high twist rate for the bars, or slower like a Turkish twist. Any advice is much appreciated

-

So after many years of fighting with my little Lincoln mig welder, I finally gave in & bought a new machine. I set out searching with a few parameters in mind. I wanted a do all machine. I weld mig, tig, & stick on occasion. Something good for stainless, & carbon steels (I tig copper occasionally as well). I won't weld aluminum, so that wasn't a consideration to me. I wanted light weight & multi voltage 110/220v. Esab Rebel emp 215ic is what I ended up with. Was under $1800 USD (with an extended warranty) from Amazon. Comes with every thing a new welder would need to get started. Tweco mig, tig, & stick leads. Fairly nice Victor regulator (I prefer a floating ball type, but this will suffice). Tweco ground clamp. 2 pound spool of wire. Gas lines. You can get a foot controller, but I didn't. The machine itself comes in about 40 pounds & seems to be well thought out & designed. Has built in roll cage type housing with several built in handles. Handy if you plan on moving it a lot. There is a large color display. 4.5" or so I think. It'll quite literally tell you everything about the machine. What process you're set up for, polarity connections, ramp up & down for tig welding, to spare parts numbers. There is a smig mode. This is great for a noob welder. Punch in your wire size, material, & the machine will automatically impute the best wire speed & amp for what you're welding. Its supposed to learn the habits of the user & self adjust to those as well. I'll say this, it'll lay a real purdy bead. This is with 75/25 gas. It'll run flat, horizontal, vertical up & down nicely. There is also a standard mig mode for those of us who prefer to roll your own settings. I haven't tried tig much as yet. It will handle 10ga 316 stainless just fine. I'm used to Miller tig machines & this esab seem to run hotter at the same amps as the Miller. The supplied torch is on the bulky side in my opinion but usable. I connect the gas line straight to the bottle (straight argon, ive got some tri mix as well), as I like control. I'm not having any problems with craters at all, which surprised me. I'm hoping to have the time to weld up some 1095 / stainless San mai billets this weekend with some 2205 wire. I'm curious as to how well it'll handle that. I havent run the stick stinger at all, so I can't comment there. I've only run this on 220v on a 40a circuit. Still gotta a 110v line for it. I've been a welder for a living off & on for the last 20 some years. I would be happy this machine at work. If want better / more comfortable leads though. But for home / hobby / light fab work, they're just fine. I'll get some pics up directly.

.thumb.jpg.eb7d9f7031e82b4894af06de5e82f1ee.jpg)