-

Posts

382 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Al Stephens

-

Benoit, Welcome! We all started small, I still have my first "S" hook. I have alway found repletion is the key to both speed and getting better. Examine your 1st one to the 10th one. If you don't see improvement, try and find out why. Good Luck! Al

-

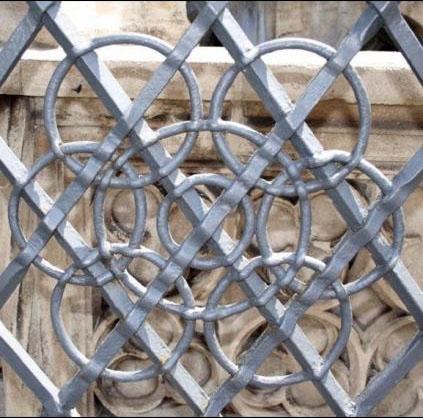

Here is a completed project photo. I didn't post last night because I was hoping someone would send me a better picture. I will go back Mon. afternoon and get one without shadows. In respect to the joints, if you go back and examine the original picture closely you will find several indications of rings that had a joint at the intersection of two points. We tried to do the same. About 60 blacksmiths came and examined the project yesterday, we had it suspended at eye level were it could be spun around and looked at from every direction. To paraphrase and sum up the comments I heard , " We know there are joints, but we can't find them". I'm still putting pictures of the process together, don't give up on me. Al Here's the "Team" Left to Right. Travis Fleming, Ronnie Howard, Dustin Patterson, Saxon Reynolds, Al Stephens.

-

Once again, thank you all for your kind words. I will post a picture of finished project this evening. Still putting the pictures taken during the process together and in order, but if someone with more computer knowledge than I have can't help they will have to be posted 1-2 at a time. I almost knocked my wonderful satellite internet connection out of orbit when I tried to email the file . Biggundoctor- The only ring that was forge welded was the outer frame ring. That was one of the many things that puzzled us during the process. Trying to figure out "how" it was done originally. Keep in mind the first one was an element in the center of a large fence section, probably 5"x6" Al

-

What do you carry INSIDE your tool bag or box?

Al Stephens replied to Glenn's topic in Blacksmithing, General Discussion

I hollowed out an old black plastic angle grinder box for my small demo/project travel kit. It will hold favorite cross peen, small ball peen, 2-3 favorite all purpose tongs. Scroll pliers, several punches, 10" 1/2 rd.file. wire brush, kevlar gloves, small towel, white chalk pencil, touch mark. And a small unopened tube of super glue, for bad cuts, which fortunately I have never had to use, and a small tube with aspirin in it. Made a copper name plate with my mark on it and riveted it to the top. Al -

Ted, the time to correct your material moving where you don't want it to, is when you first see it. Start correcting the problem with your next hammer blow, or heat. Don't move anywhere else until the problem is taken care of. Oh, and by the way, your first forged pair, is better than mine was also. Al

-

What did you do in the shop today?

Al Stephens replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexander, Very Nice. Thank you for sharing the pictures. AL -

Hello from a flyover state!

Al Stephens replied to Moly-Elsabeth Owens's topic in Introduce Yourself

Hi Moly, Welcome. If you have not met and joined BAM, the Blacksmiths Association of Missouri, look them up. Good people, lots of experience to learn from. Well established active group. Al -

UPDATE The Kuhn Ring Element Challenge, that a few of the Athens forge members have been working on will be complete and on display. And NO, it will not be in Iron in the Hat!! AL

- 22 replies

-

- misc discussions

- events

-

(and 2 more)

Tagged with:

-

The Athens Forge, a member of the Alabama Forge Council, will meet Sat. July 28, 2018 at 10AM Our demonstrator for the Day will be Ron Nichols from TN. Ron, an accomplished smith, and teacher, will be producing a Francis Whitaker style candle holder. There will be an Iron In The Hat drawing at lunch. As always visitors are welcome, for more information and directions visit the website at Athensforge.com or the Athens Forge page on FB.

- 22 replies

-

- misc discussions

- events

-

(and 2 more)

Tagged with:

-

Thanks everybody. Lou, one of our first steps was to make a full size drawing. The large ring holes were laid out with dividers based off of the cross members and the working drawings. We made a ring from square stock with punch marks at 1" increments to figure out hole location on the six outer rings. Al

-

Since it looks like we are actually going to successfully complete the project, we have decided to reveal the "team". It was made up of 5 members of the Athens Forge. Travis Fleming Ronnie Howard Dustin Patterson Saxton Reynolds Al Stephens Al made the "working drawings" based on a picture taken of a section of the fence around the schöner brunnen nürnberg, Beautiful Fountain, in Nuremburg Germany. All work has been performed at Travis's, Artistic Anvil, in Athens Alabama. The project will be completed with a ring frame. As in " One Ring To Bind Them All". Apologies to J.R.R. Tolkien.

-

I would use JHCC suggestion and drill and tap the hub. Good Luck. Mine is still in storage, but I have time to work on it now. Al

-

Very, very nice! Clean, solid, functional. Al

-

I like it Joel! Nice job. Al

-

I have tried to keep fairly detailed notes, and pictures throughout the process. Time spent, tools made, successes , and failures. When we get done, if anyone is interested, I'll try to boil them down, and post them. I will say that there has been a lot of time spent looking, and trying to figure out "Where do we go from here", and "How do we get there." Thanks to everyone for the kind words, and encouragement. Al

-

On June 18 I started a topic labeled "Information Needed". I encourage everyone to look there for further information. Since then several smiths have spent many hours on this project and there are many hours more that will be spent on it. The post title refers to the 1587 locksmith Andreas Kuhn that is credited with producing the original element. I thought I would share our progress up to now, and let everyone else join in the head scratching. Here's the pic we started with, and where we are now. And, Yes, we have modified the design. Al