-

Posts

382 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Al Stephens

-

-

A one time student, and now long time friend uses the following statement to his students which he attributes to me. "It's better than perfect, it's done." I'm sure I followed it to him with, "Now do another one." Al

-

Bigb, I had rotator cuff repaired 3+ months ago, Dr. also removed more bone spur from the area, and worked on my biceps, again. I am not able to do much of anything yet. This was my 3erd surgery on that shoulder/bicep in less than 4 years though. Dr. says rotator cuff has healed, my issue is in the bicep. The surgery has at least given me relief from the pain I was in prior to the surgery. I am able to sleep in bed, all night, some nights. This was all on my hammer arm, looks like I'm going to have to learn to work with other arm. Good Luck! Al

-

DRoberts, I'm impressed! Never saw one melt the end of a bar off before. What was the material size? More info. please? I have been of the opinion for a while that induction forges would be a way to get blacksmithing demos in to "pubic" places that were concerned about fire in any form. Al

-

Zeroclick, It looks like the hair pin has a twist in it. When I made these for my daughter and her friends they always wanted the pins as smooth as I could make them. They didn't want anything to get caught on and "pull" their hair. Al

-

Momatt, I like it. Very nice. Thanks for sharing. Al

-

Just a reminder, the Alabama Forge Council will hold their 2108 Conference next week. Sept. 6-9. Feature demonstrators Terry Sheridan, and Justin Brown. There will be tailgate sales, first come first serve, cash is king! Iron in the Hat, Auction, great displays, the Kuhn Ring Project will be on display in the Athens Forge tent, not to mention a tall tale or two told. Plenty of camping room. For more info and registration form go to www.alaforge.org See you there! Al

-

Hi Raceman, I would suggest that you just use your rr track as you get it. There are a lot of basic forging techniques you can practice without any time spent "shaping". if you have a short piece stand it on end, tie it down, and forge on it that way. Remember the only place you will be moving metal is between the face of your hammer and whatever surface your material is laying on. Take the time to go thru the links Glenn sent you. Good luck, be safe, show us your results. Al

-

Keep up the good work Mark. Al

-

The Athens Forge, a member of the Alabama Forge Council will meet Sat. Aug. 25 at 9AM. Please Note meeting time change!

Our demonstrator for the day will be Robert Taylor from Birmingham, AL. He will being doing a copper weather vane. Robert has been working with copper a long time and is an excellent instructor. He has taught many workshops for local groups, (several for the Athens Forge) and classes at J.C. Campbell Folk School. If you have questions about working with copper, this is the meeting to come to.

There will be tailgating before/during/after the meeting. A 100 lbs. Vulcan, will be for sale $400.

There will be an Iron in the Hat drawing.

As always, visitors are welcome. For more information visit the website at Athensforge.com, or Athens Forge on FB

-

Spanky, as with most of the project, it was a combination of input and labor from everybody that came up with this. And yes there was a lot of smiling and high fives the first time it was spun around. If anyone has not seen the "spinning" video it is posted on the Athens Forge , and The Alabama Forge Council FB page. Al.

-

Koke, Very nice, I'm sure they kids will remember it, and a lot of us "not kids" for a long time. Al

-

We never even thought about the radio until we played it back, but then though "how appropriate". Thomas, I don't know of anybody going to Quad-State as of now. Al

-

-

Here is the completed project. It's been a terrific learning experience. It will be on display at the AFC Conf. Al

-

If you haven't drifted the hole to it's final size. Try cooling off the "large" side of the hole, the side moving more than the other one. Then drift to final size, the hot side will move more than the cool/cold side. Al

-

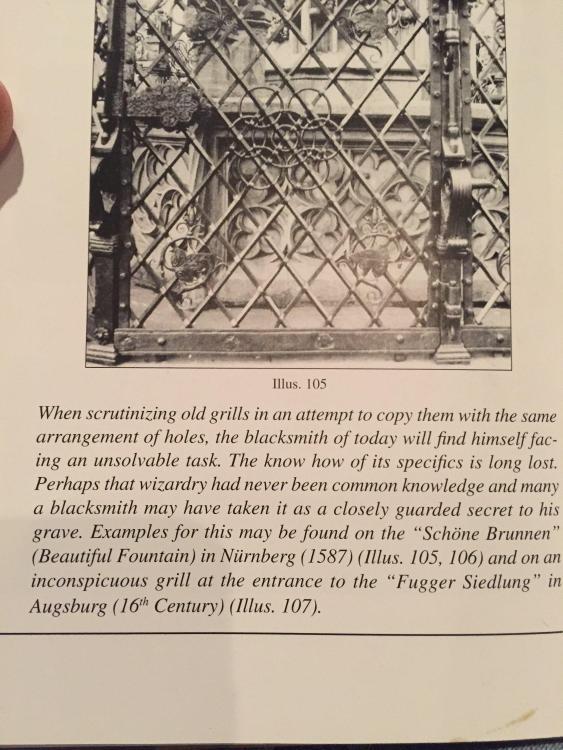

The team got together again yesterday to work on a display stand for the project. The plan is it will pivot between 2 points, so it can be spun and examined from all sides. It will be done by the AFC Conf. While planning I was shown a book, "The ABC'c of Blacksmithing", republished by Blue Moon Press. And look what we found!!! Don't know how many hours I spent looking for this picture when the project was in the planning stage. This is a real good book with a lot of information in it.

-

JHCC, We are still waiting on SI to give us a price and timeline, but have told them we want to do it. We have repeatedly emailed those we have been in contact with and the last several have not been replied to. The last time we emailed was 7/24.

Don't know if more people contacting them would help, or hurt. Whats everybody think? We haven't forgot or given up yet. Al

-

Ranchmanben, Nice Shop! But I have to ask, where's the chimney for the coal forge? Or is it a "down draft", if so we need LOT'S more pictures. Al

-

Feature demonstrators for the conference will be Terry Sheridan from Canada, and Justin Brown from AL. The Kuhn Ring Challenge project from Athens Forge will be on display. For more info. and registration form go to www.alaforge.org Al

-

Gaswizard, I really like the work, AND your drawing program. It would be much easier to remember things from one job till the next time you use it, than my crayon notes on scrap paper method. Thanks for sharing. Al

-

Thanks Scott. Just as the pictures show, we started in the center and worked out. That was a method taught to me years ago, and has always worked well. All most everything passes through the 2end, and largest ring. Once R2 was in place, it was a case of looking at which ring intersected with other rings and the sq. cross members, and figuring out what needed to be done to get them in place. There were no forge welds on the interior rings, the farther we got into the assembly the tighter everything got. Our piece really kinds of holds itself together. Al

-

No, but as I remember all the coyote's stuff was ACME. Al

-

Frosty, actually some of the closure joints were hidden where a round ring passed through another round ring. There was one ring that had a small tack on it to hold it together. But if I try to tell which one I'm sure my fingers will swell up and I will never be able to type again! We found that the farther along in the assembly process we got, the stiffer everything became. After the frame ring was installed we went back and tightened up 8-10 joints. At that point we couldn't find anything else that was loose, and could produce no more "rattles" so we decided to leave well enough alone, and put the finish on it. That was how it was put on display Sat.

As I have been promising, I will put a PDF file below with some pictures and captions. I'm sure it won't answer every question that everyone might have, but it's a lot more info. than we had when we started. If anyone come up with a better way to do it. Please, show us the pictures. Where not sworn to secrecy, I will attempt to answer questions.

Once again thank everyone for your kind and encouraging messages. Al

-

The answer I got was an ACME! Al

Athens Forge 2018

in Alabama Forge Council

Posted

The Athens Forge, a member of the Alabama Forge Council will meet Sat. Sept. 22 at 9 AM. Please note meeting start time change.

Our demonstrator for the day will be Athens Forge member George Ezell. George will be forging a billet and a blade or two from that billet. You can see examples of his work at Relic Forge on FB. If you have questions about a Seax style knife, George is the one to come and ask.

One never knows what will be at the meetings to buy, sell, or trade.

Visitors are alway welcome. For more information, and pictures of past meetings visit the website at Athensforge.com, or Athens Forge on FB.