-

Posts

1,966 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Mark Ling

-

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes. Smart man. Got it a bit of time, forged pair of 1/2” v bit tongs and my first ball pein, what I’d consider to be a proper ball pein, with the eye punched in the center and so equal weight faces, what I find to be the logical way of doing it, haven’t figured out the reasoning of having an un balanced head. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you. Today wasn’t too great of a day, things didn’t go too well, burned myself pretty good, and I also should have had another pair of hammer tongs made, but I managed to burn both of the reins after drawing them out. Just one of those days. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Didn’t get as much done as I’d like to have, got up late and ended up not starting till after lunch. Made a couple eye punches, round punch, slot punch, and fuller, cupping tool, flat jaw tongs, and hammer tongs. Also got to finish the legs for a coffee table which I’m excited about. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you. Yes the rowel is copper, cut a sliver off the end of a 1-1/2” round copper bar, and filled to shape. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

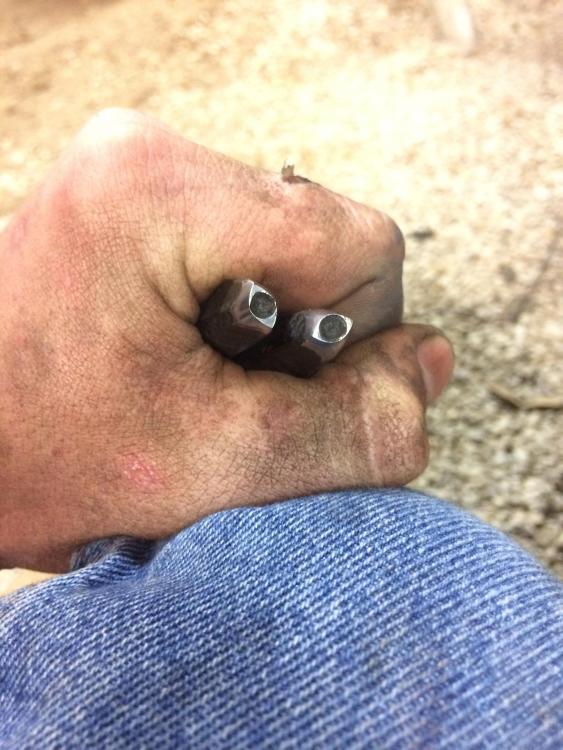

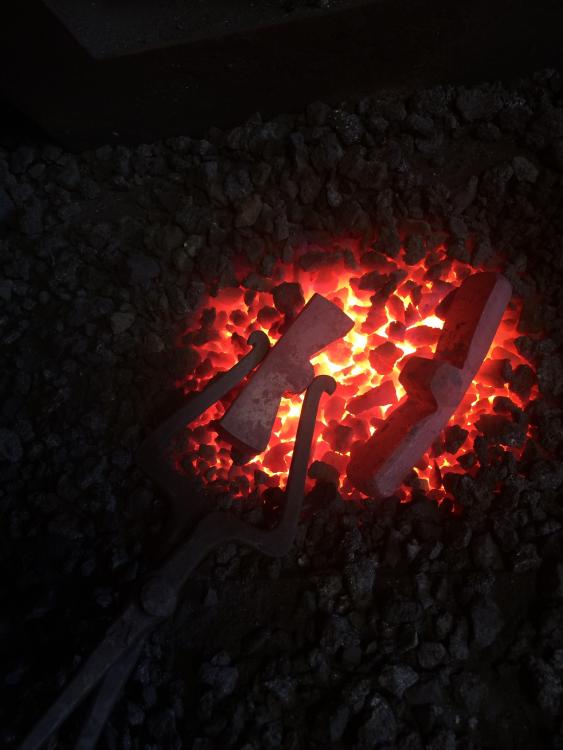

Forged a pair of spurs. One piece spurs, forged from 1” square. Included a picture of them part way through, gives an idea of the isolation of material done with butchers. -

First center punch. Really pleased.

Mark Ling replied to Eventlessbox's topic in Slitters, Punches, Drifts, etc

Seems I’ve thrown probly thousands of dollars in hammers and other tools in our pond...lol. If I kept them people would start wanting to buy them. Many of the tools I throw out is mainly just for aesthetic reasons, functional tools, but just don’t meet my standards to sell. There’s a big difference in functional and sellable, at least to me. Maybe it’s just called pride, pickyness, or high standards, or maybe all those things are the same. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

That’s very interesting thought Mr. Powers about you can either be doing stuff or taking pictures. Obviously it’s hard to do stuff while taking pictures but I feel like I still get a lot done and I take quite a few pictures.....though for me it’s somewhat more necessary in the means of making money, makes things a little better when a customer can see what they are buying and even better when they can see pictures from the process. The later is a bit more difficult to do, but with one of the latest classes I did I had a photographer come out and take plenty of pictures. It seems like most of the “admins” of the site I never see pictures of their work...wether it’s cause they’re rarely in the shop, it gives the illusion nonetheless. Or if it’s cause they’re just too busy to stop for a few seconds to take a picture, or worried about being able to be tracked, I’d really love to see some of yalls work. Y’all are people I admire, but as I think about it more, I admire y’all for the kind of people y’all are, not yalls work, cause I rarely, if ever have seen it. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

He’s been converted welcome to the rounding hammer cult. -

Help with ID on 280lb English anvil

Mark Ling replied to Mark Ling's topic in Anvils, Swage Blocks, and Mandrels

Yup I’m back Hey Jonah! I think you may be right. There is quite the similarity. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Round the edges of your hammer face over some, it shouldn’t be leaving marks like that. Either that or practice hammer control. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Angle grinder with a cut off wheel same way Brent Bailey does it. There’s a video of him showing how he does it, though it’s pretty self explanatory. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Few more things. Small belt axe that was forged in a class in between heats of forging a hammer, and then a large hatchet I made and a smaller sized framing hammer. -

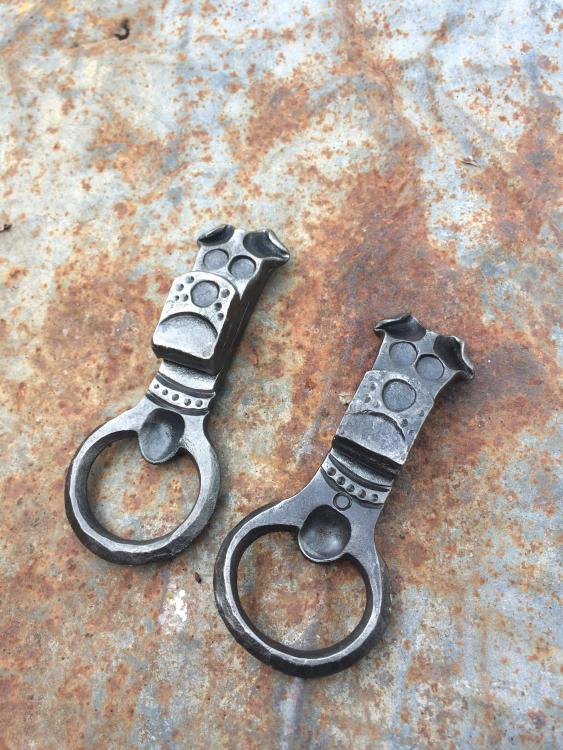

Show me your Bottle Openers!

Mark Ling replied to Arbalist's topic in Blacksmithing, General Discussion

-

283lb English double horn anvil. Paid $900. Won’t probly get used for other than a cooling rack, just too big of an anvil, but I still like it.

-

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks everybody. I do them in my hometown, college station Texas. Though beginning to plan some in other states. Some more stuff... that little cross pein I made, was inspired by the old one sitting next to it in the picture. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Been giving quite a few classes. A few of the pictures are from a three day tool making class a father and son from North Dakota came and took a couple weeks ago. The rest are from one day hammer and hot cut classes. -

Hey guys...been a while since I’ve posted. Lots has happened since the last post a year ago or so. Anyways. Picked up this anvil the other night, probly won’t use it much but at $900 I figured I’d pick it up. Weights 283lbs, the only marking I can see is the stone weight and maybe part of a U? It’s pretty pitted, and didn’t know of maybe one of y’all would have an idea on the maker. Also included a comparison of it sitting next to my 170 or 180lb (don’t remember) Keen Cutter.

-

I'm thinking I should take a break from the site I'm not sure it's what it used to be, or maybe I'm not what I used to be. I'd like to thank most of y'all for being as helpful, encouraging, and as generous as y'all have been. Y'all have helped me be a better smith and a better person mostly. Y'all have encouraged me when i needed encouragement and have given me pointers when I needed critique. I'm going to be off of iforge for a while maybe a year or two and I will check in then and see what the site is like then. Those of you if you ever need to contact me I have given you my number or we are acquainted on other online platforms. Thanks again for everything I'm not sure I would be where I am today if it wasn't for y'all. Keep the forge hot and the anvils ringing, I know I will. Mark

-

New International Young Smiths Group!

Mark Ling replied to Mark Ling's topic in Events, Hammer ins, Where to meet

Yeah thanks everybody Im Looking forward to it. yeah I would say I have been conditioned for the summers there. -

Very intersting. Never had heard that learn something new everyday I guess.

-

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Made this the other day and finished it today. 18 oz. I used large radius fullers in the diagonals. What y'all think? IMG_2075.mov -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

Oh ok that may not be so bad I thought it was flush. Yeah it looks German I like the German style ones I want one. -

What did you do in the shop today?

Mark Ling replied to Mark Ling's topic in Blacksmithing, General Discussion

ColoradoCJ- Nice looking leafs especially the one on the right the veins look good. Peppie- That's a beautiful looking leg vice, but having the jaws flush with the table could be helpful for some uses, but may also limit the use greatly. Why do you have it like that?? Littleblacksmith -

Hello everybody, so, Brian and Ed Brazeal have put together a new international young smith group, they are currently in Brazil at the moment. This is not the first group that has been put together, in the past a few of the people who it has consisted of is Alec Steele, Daniel Lea, Dave Custer, and Daniel Riffe. The purpose of this group is for Brian to teach the young smiths so that they can then go back home and teach it to others. This group consists of myself (Texas USA), Jonathan Pinkston (Kentucky USA), Jeroen Smit (Gronsveld Netherlands), Andrew Larson (Kentucky USA), Ferraria Tavora ( Ceara Brazil), Hudson Lobo (Brazila Brazil), and Jason Ellard ( Australia). I feel like I may be forgetting someone, apologies if I am. The plan is for about 6 of us to head to Brazil next summer around July or so and spend some time there learning from Brian and then also teaching others who are there once we have been put through the tools to make tools curriculum. I know almost for sure I am going next July for about 2 weeks or so. I'm pretty excited about it let me know what y'all think about it!