-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by GlassCowboy86

-

Haha! Error, that depends on when the last time the furnace was charged!

-

Thank you, and thank the rest of you for all the prayers and well wishes for my little Gidget! She was released to come home last night, she's doing a lot better, though we aren't quite out of the woods yet! But breathing treatments and medication are definitely helping and it's no longer life threatening as long as she doesn't get any other sickness to compound it. So she is being spoiled and all of my "normal" rules for letting her cry and self soothe and not picking her up anytime she cries, have gone right out the window! now if I can get this burner tuned to where I'd like it, we will be good to go! Lol.

-

I believe that my mig tip jet wasn't seated properly and that was causing some slight leakage which caused the flame out the back end. I did some change up and reconfiguring to get rid of that. So that is no longer an issue. The mig tip is a .035 and yes it's the 3/4 burner we've been talking about.

-

I needed to do something this evening, my 6 month old little girl had to admitted to Cooks Childrens Hospital earlier today, she has RSV a respiratory virus. We took her to Cooks yesterday, they gave us a machine to give her breathing treatments and sent her home. She was getting worse, so we took her back and they admitted her. I had to be the one to come home and look after our 2 year old son, I put him to bed hours ago, so I have been sitting around thinking about my little girl. So instead of stewing on it and worrying and ripping out my hair, I decided to get my burner assembled and give it a shot. Please let me know if you have any Constructive criticism or advice on how to get this thing running as best it can. I know it needs to be tuned and worked on a bit, I just wanted to fire it up and see what y'all thought. Thank you. This is a slightly modified version of the Frosty T burner. Thank you for all of your help Frosty. 20160112_222655.mp4 20160112_222310.mp4

-

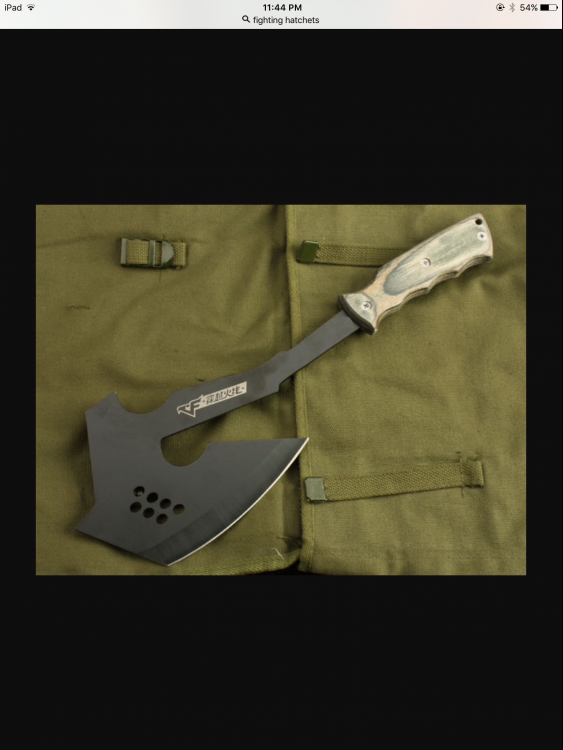

I think I'd do ok carrying a few of these bad boys around with me! Wouldn't be worried about anyone with a sword either! Lol.

-

Steel, I get what you are saying, but that's kinda like saying the only reason to have a pistol is for dueling, I guess some people like that idea, I however do not. Haha. If I'm gonna carry a blade as a weapon, instead of a tool like a pocket knife, then I'm carrying to do business, not challenge someone to first blood to protect my honor! But that's just my take on it!

-

I like the idea of carrying blades like swords around on a daily basis, however, I don't think I would be the sword type. I personally feel like I'd be the guy with a pair of wicked looking hatchets call the "wicked sisters" or something like that! Lol.

-

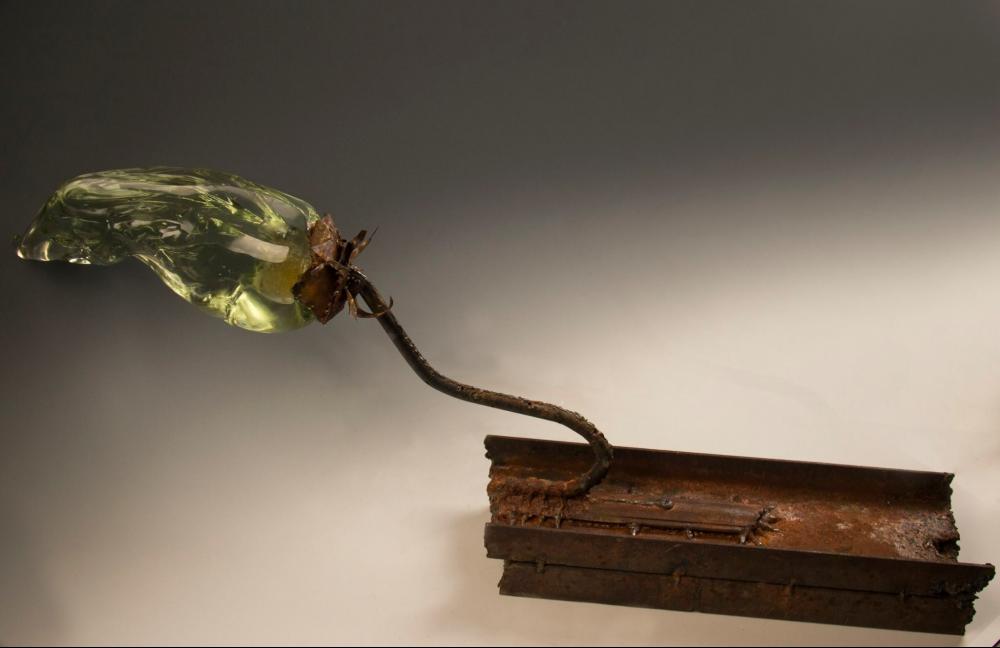

Frosty, what post disappeared? I've no clue about that one. I think borrosilicate glass can do well with steel, I'm no expert, but I know it has a higher tolerance when it comes to cooling than soft glass does. But the glass I use, COE 96, doesn't play too well with steel. If there is no barrier, carbon or I use widby island mud, the steel cools faster than the glass and cracks. I know you can sometimes get away with using the 2 together if the steel isn't encased in the glass. Boro, what you referred to as lamp working glass, also known as Pyrex, has a completely different COE than the glass I work with, it's also got a different melting and annealing temperature. The glass I use is pretty finicky but tends to work better on the larger scale and in my opinion is prettier. I guess it all depends on what you know and how you learned etc. but that little cross is pretty rad, did the glass stick to it?

-

Heap- thank you very much! I really appreciate it. IronWolf- I am an offhand/hot glass/hotshop person, lol. I've wanted to learn torch work, we have a Carlisle and a smaller single burner torch at the shop I work in. We also have a metal studio available, but we don't have a forge, hence why I am building one. A metal tree with glass leaves would be super cool, I'd suggest using Hextal to glue the glass to the metal, once it's dried it'll be harder than the glass and near as hard as steel, plus it's archival. I am a member of talkglass.com, same name, the other one, I'll have to look it up, thanks for the info. Just for reference: the glass in the first two pictures weighs about 40 pounds, and 2 feet long. I made it while blindfolded, cuz I'm a little crazy, haha. The piece in pics 3&4 weighs about 25lbs and it took me about 35 hours to carve through it. The piece Heap called a tongue over a wrench, pretty accurate description, though not necessarily what I was going for, is about a foot long and a foot high and weighs about 20lbs. the last pic is a close up of a large piece I stretched over a piece of steel.

-

here are a few pictures of the things I've done thus far that use both metal and glass. Daswulf, appreciate the input, I know a guy who does these odd insect like creatures, but they are all glass, I have a small idea building off of what you said that would use glass and metal, but would also fit into my "theme" of PTSD and mental health, something akin to a winged insect from a Rorschach test (ink blot test). Heap, glad to meet another newb, and I appreciate the input, the only problem is see with dangly glass things is this: I tend to work with very large glass pieces, that are very heavy, whatever they dangle off of would need to be pretty substantial as well. Lol. If you look at the first two pics I posted you can see the heavy glass that I had to balance with a very heavy steel base to make it work. ianinsa, glass is awesome, I hope you get back to it one day. Metal and glass aren't really good bed fellows when the metal is inside the glass, the cooling temps are just too different. With steel it cools so fast that it creates a thermal shock inside the glass, you have to have some sort of layer in between the two, copper works pretty good though, but it is a balancing act. You can see in one of my pics, the ones with the dark lines running through the glass, those are copper inclusions. big gun, you are right, it's been done quite a bit, a lot of it is glass being blown into metal, which I've done. I know I'm not coming up with a new idea, but I'm looking to come up with an interesting way to make the two crafts play off of one another, I'm just not sure how I'm gonna do it yet. I'm not a huge fan of doing lighting type stuff, it always looks either too kitschy or too commercial, I've done it, and could do it again, it's just not my thing. One idea I've got rolling around a bit is forged torture type devices that I either blow or slump glass into or on. I want to do something huge, but of course I need to get my forge running first! Thank you guys for all the input! Keep it coming, no idea is too off the wall or crazy!

-

Ok, well first off, howdy all, my name is Ray. I am a glassblower from Fort Worth Tx, I've been blowing glass for about 4 years now. I decided to build a forge, a project I'm still working on, but I've done a bit of metal work, and I really enjoy it. So, as for my idea, not really much to go on I know, I want to use smithing with glass, I graduate with my degree in art, with a concentration in glass, in May. I'd like to see what y'all think of the idea and what y'all think would be cool as far as using smithing with glass work. A bit of background, I am a disabled combat veteran, my work is mainly abstract sculpture with idea being that each piece is made by me trying to put crazy stuff in my head into the piece. I'd appreciate hearing what y'all think of the idea. ~GC