-

Posts

37 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Redneck carp's-tongue

-

I've used a relatively unmodified hairdryer as a bellows before; the issue is directing the air. I've drilled holes into a pipe and stuck a male PVC socket onto the end, which matches a female PVC socket taped to the mouth of the dryer. cap off the end of the pipe and stick it under the coal, and you're good to go!

-

Blademithing series on History channel

Redneck carp's-tongue replied to Frosty's topic in Knife Making

from the Sword Breaker Redemption: Wow. out of all the possible pop-culture references they could have used, they did SAO: HF! granted, given the show's nature a reference to Sword Art Online was inevitable, but I find myself asking why reference the more obscure games? Or mention the character of Philia so specifically. (She does start with a sword breaker, but given the fact that she was basically in an extreme survival situation it wouldn't have done her much good). I'm actually kind of happy they made that reference. The SAO games are underrated and the characters exclusive to those games are similarly obscure. -

I saw a Wakizashi in a book that looked so similar to this sword one could swear they were made as companions. It seems just as high-quality, though; nice job!

-

The washer hilt looks like an M3 or a KA-BAR. Really hits the period vibe!

-

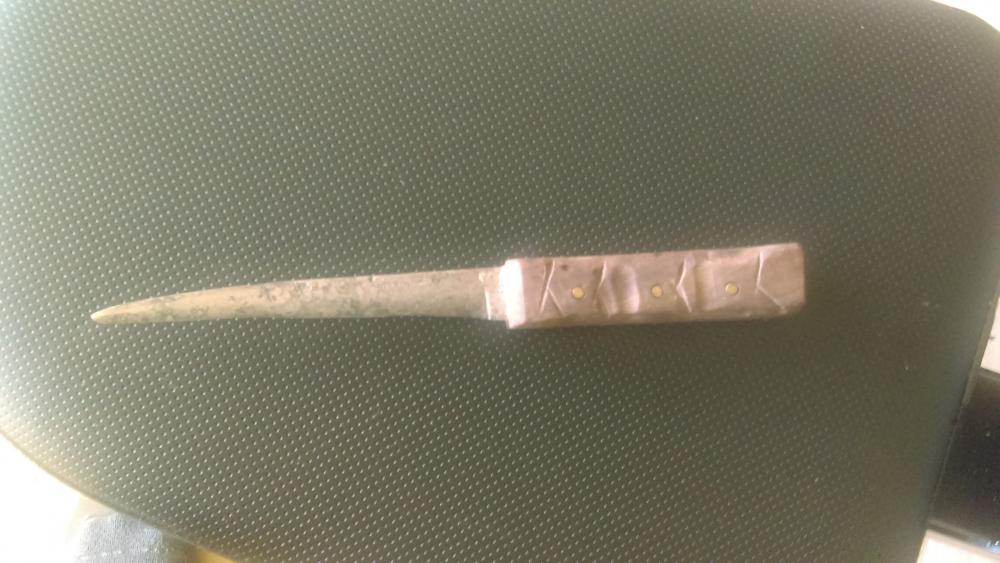

Backyard Bichaq, now with handle scales.

Redneck carp's-tongue replied to Redneck carp's-tongue's topic in Knife Making

It would probably have been better to say makeshift, rather than post-apocalyptic. An oven isn't a hard thing to build anyways, but that's beyond the point. -

During the long sabbatical I've had from this site, I've managed to quench and scale my knife. It's horribly simplistic, with basically square blocks that have been notched to give a grip and have had finger grooves carved into them. The heat treat was also post-apocalyptic; It was quenched in a can of oil and tempered in my oven. If you can see the images (I'm not exactly sure because they're not inserted), could you tell me what you think?

-

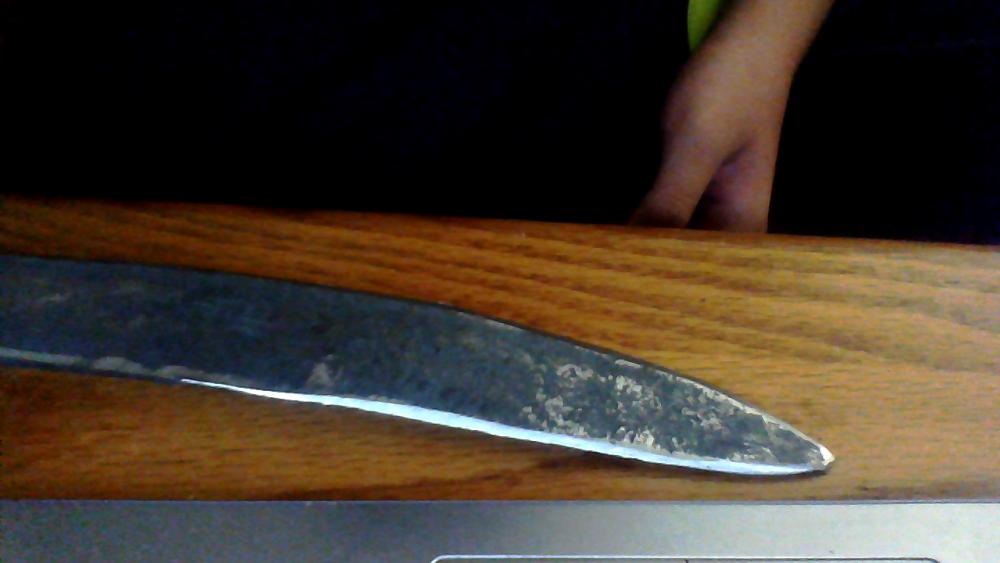

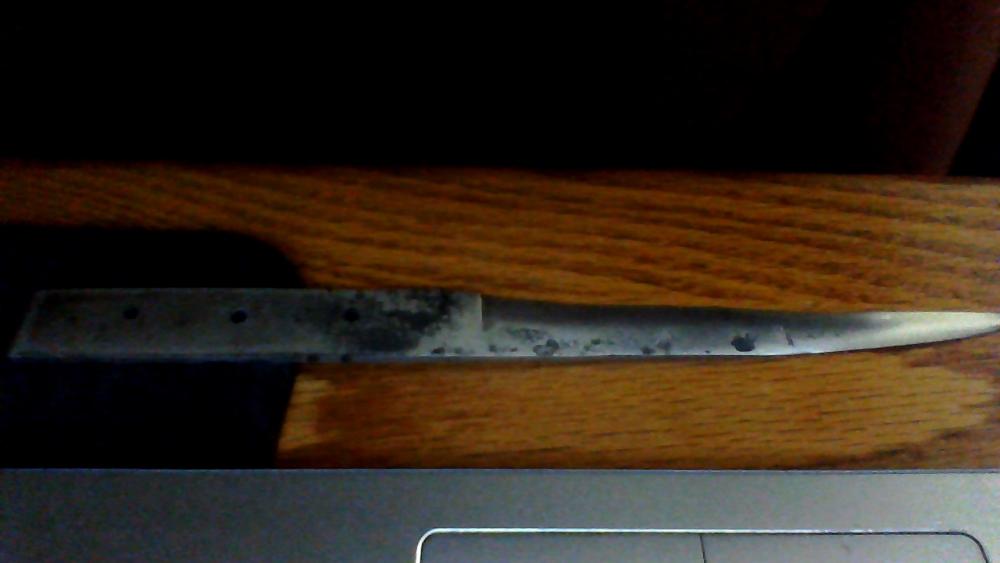

Alright, in the weeks since I posted this, I did some additional work on the Backyard Baselard: As you can see, it's been polished and I've begun to put an edge on it. It may be difficult to see, but the tip has been sharpened (as can be noted from the harsh taper in the last two images. I am also proud to present: The Hillbilly Hanger! This is an 18.5in. Shortsword me and my dad made from one of the few remaining pieces of high-carbon that was lying around. It has two edges, both of which are the length I want them to be. Namely, it has a yelman point (with a short second edge). The Hanger will be fitted with an axe-handle hilt with a piece of brass for a guard, with two counter-curving quillons made from copper on either side of the guard, secured through loop-holes. I based this one off of a British Navy Hanger I saw in the same book on knives that I used to design the other two. Though I still have a ways to go before I even quench the last two knives (I've already polished the first one to my liking), what do you think of the Hanger? On the same topic, what of the Baselard?

-

A railroad spike? Are You Serious?! That being said, it's quite impressive; I like the damascus pattern towards the end of the edge.

-

Wow! That is one of the most beautiful blades I have seen on this site. I wonder, what wood is the handle made of?

-

Wow! Quite beautiful (in a rustic way).

-

Thanks! Really! Both of my blades are 1095 high-carbon. I do have a third, but it's much longer and even newer than the Baselard. It's also 1095. I do have the book handy, but given that I can only photograph using my laptop camera, It's too difficult to simply take pictures of the book. The book itself is "The Complete Illustrated History of Knives, Swords, Spears, and Daggers". The Balkan Ottoman Bichaq on the upper part of page 222 inspired my first knife, and the English Long Baselard on page 131 (the second one down) inspired my second.

-

I really like the "French Dragoon" (At least, that's what I call it) Hilt. "I call it the French Dragoon because I saw a French Dragoon longsword with that same exact type of handle) This looks like something you would find in a museum, just less old and damaged.

-

That Feeling When Things aren't Perfect

Redneck carp's-tongue replied to HEAP of JEEP's topic in Knife Making

Quite beautiful to me, but beauty is in the eye of the beholder I guess. Of course, I tend to like functional knives more than artistic ones, but that's just me. -

Blademithing series on History channel

Redneck carp's-tongue replied to Frosty's topic in Knife Making

Rather obvious. I have seen more stupid decisions on that show than I could count. More than can be just chalked up to inexperience or competition pressure or whatever. It's a fun show, the one that got me into bladesmithing (I do actually want to compete in it, but It's likely that it will be canceled before I am experienced enough to), but yeah, same goes as with all the other reality competition shows: too much theatrics, not enough thought. -

I have currently been working on two different blades since the "First Knife" post; one I've been working on since before this summer, and another I just started a couple weeks ago. NUMBER 1: I call it the backyard Bichaq, because the design was inspired by an Ottoman Bichaq I saw in a book on knives. As you can see, it is very close to finish: the only two processes left for the bladework are quenching and tempering. Given that this is effectively a first time father-son project, it's (in my mind) very good for a first time. What do any of the more seasoned bladesmiths here think? The Backyard Bichaq is partially double edged; the upper edge is much shorter that the lower edge. It already has holes drilled into the tang for brass pins, and I plan on fitting it with a walnut-scale handle and a brass guard. it is about 9.2-3in. long NUMBER 2: This one I call the Backyard Baselard. As you can see, it has been shaped in the forge extensively but is relatively fresh to filework. It has sustained some slight cracking and material loss as a result of its thinness, and is slightly warped towards the tip, but I have faith it will make for a great blade. If it breaks, I will just file it down shorter. Again, do any of the more seasoned bladesmiths want to share their opinions on this one? I have plans to fit it using a partial "Baselard" Hilt using two guards to produce the "I" shape that dagger type is famous for. One I have plans to fashion myself (out of copper) and the other I saw in a catalog from Jantz Supply. The rest of the handle will probably be either walnut, kirinite, or (if me and my dad are feeling ambitious) some African Blackwood we bought a while back at the same place we got the walnut (because it was on sale). The baselard is about 12.5in. long So, what do you think? Given that I jumped into the complex process of bladesmithing the first opportunity I got, did these turn out very well given the time, effort, and work I put into them?

-

Given that I lack a specialized tempering oven, I was wondering if it is possible to temper blade steel (I'm using 1095 currently) in either a kitchen oven or a grill. I really don't have the money to buy a tempering oven, which is why I'm asking this question in the first place (yes Steve, before you chastise me rather than answer this question, I did look for a similar question and couldn't find anything). There is, however, a problem that I see with using the oven: It is in a kitchen, and my forge is outside, so I'll also ask how long does in take a quenched, untempered 1095 steel blade to crack after the quench? Perhaps if I move this post to the blade heat treating section ......

-

Blademithing series on History channel

Redneck carp's-tongue replied to Frosty's topic in Knife Making

Makes sense. -

Blademithing series on History channel

Redneck carp's-tongue replied to Frosty's topic in Knife Making

Uhhh...I'm sure somebody has asked this before, but has anyone on this site actually competed on Forged in Fire? Did you read any of this thread? -

Wow, pretty good! It's quite rustic in appearance, and it kind of reminds me of an axe.

-

Listen to the Curmedgeons and be patient...

Redneck carp's-tongue replied to Worshipdrummer's topic in Knife Making

Back to the main topic of the thread: in a word, yes, you should listen. Oh, and you also should manage to explain yourself pretty well too. one person though I did not have a forge at one point (even though I do). Plus, like you (worshipdrummer), I have been working extensively since my last thread (the one involving practising on the mild steel). I managed to buy some 1095 steel, work with it, and produce a blade. I am midway through finishing the blade (it isn't heat-treated or tempered yet, though; I thought it would be easier to do the majority of the finish work on the blade before the quench) and my dad fashioned two wood blocks that will become a handle for the finished knife. it's coming along rather nicely. I have taken pictures of my project, though uploading them may be a problem. All the images are on a school-issued iPad and the computer I'm posting from is a PC.