Forgingnoob

-

Posts

18 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Forgingnoob

-

-

It's and 8 the label is rubbed a bit there.

-

Thank you very much steve.

-

-

-

7 hours ago, ThomasPowers said:

The short answer is NO! Have you ever seen any system with dual motors running the same shaft?

Do they make a differential for electric motors?

-

Is it possible to use 2 motors? I have a small 3/4 HP motor from an old belt sander.

-

2 hours ago, WayneCoeArtistBlacksmith.c said:

You will need a 56C face frame, Are you going to have a single speed or use a VFD for variable speed? If so you will need a three phase motor.

Let me know if I can help you.

Wayne

I ordered a single phase 1hp 56c motor. Could I use a Variac as a veriable speed? I'm not too keen on electronic motors.

5 hours ago, ThomasPowers said:When I needed motors I like to go to an oldschool motor repair place and ask them. They generally have some that folks dropped off and then left them when they found out how much the repair costs. I've often gotten a good deal that way.

The only place I know of around me that sells electric motors is Tractor supply Harbor Freight and a little RC shop.

-

I need help finding the cheapest way to get my eerf grinder going I've been looking for a motor for weeks and the only thing I've found was a jet pump motor that doesn't fit.

-

Could I use English wheel bottom anvil wheels for a flat platen and tracking wheel?

-

I found my issue I didn't draw out the hilt area as much as I did the center and tip so when I let it cool it turned on me. I believe I have my problem fixed for now I did a combination of what ThomasPowers and Prevenge suggested it I pressed any noticeable waves out with a vice and then flattened it out more it seems pretty straight so far but it's still cooling.

-

On 4/18/2016 at 6:05 AM, Prevenge said:

What is it made of by the way?

A file its W2 steel I believe

-

II started working on a dagger its the first thing I've ever made by forging.

I have it annealed until I can afford to make a filing jig. I noticed that it is twisted, but otherwise straight. Is there a way to fix this. My anvil is an 1899 75lb Fisher and it's very warn and has some pits in it if that helps.

-

On 12/31/2015 at 4:54 PM, Frosty said:

Yeah and I see people operating vehicles on public roads every day who think the turn signal lever are for keeping the PO key handy, not answering a text is stupid, etc. etc. Life is full of idiots learn what NOT to do from them and keep out of their way and their hands OFF your tools.

When you say you "know them", is that in person or online? Be very VERY careful what you believe on Youtube till you know enough to filter out the bull nuggets.

Frosty The Lucky.

I know them personally. And I watch YouTube carefully and research what people say I've been researching bladesmith and blacksmithing and I know a blacksmith personally who says he would teach me a bit, but he works 2 jobs.

-

21 hours ago, Frosty said:

Welcome aboard new guy, glad to have you. If you'll put your general location in the header you might be surprised how many of the IFI gang live within visiting distance. ONE day working with an experienced smith is worth maybe weeks or even months figuring it out yourself.

My recommendation is to learn the blacksmith's craft to the point of proficiency before you delve into the specialization of bladesmithing. Trying to learn both at the same time is compounding the effort and maximizing the probability of failure. Set yourself up for success, it'll get you farther faster.

Frosty The Lucky.

I know guys that "make knives" but they aren't bladesmiths. They buy knife kits from smkw. I know one guy who used to forge knives but be thinks after you quench its hardened and tempered and just needs to be cleaned up.

-

21 hours ago, ThomasPowers said:

At your current level may I commend to your attention "Step by Step Knifemaking" by David Boye which is available online now. Now what I would suggest for someone wanting to do "art" knives but for reusing ag scrap it's a sturdy start.

Look up "spark testing" and "Quench and break testing" as methods to determine if an unknown alloy will work for a blade.

Most tools like wrenches are medium carbon steels and so not the best for a blade.

Sorry for the terseness, the original long post is swirling down the bit bucket somewhere.

I will have to check it out ive been saving money to get a forge for the last two years,( I have a forge now) I've watched hours of videos from Walter Sorrells and a lot of other youtubers. I've also read "50 dollar knife shop" and "The Complete Bladesmith"

-

I have a collection of antique tools.

I have some old ice block tongs and I was curious. If I make a k ife out of them will it harden they seem to be made of the same metal that old cotton scale balances and hooks were made of.

Also I have some old monkey wrenches I want to make knives out of.

I have no experience in metal working of any sort.

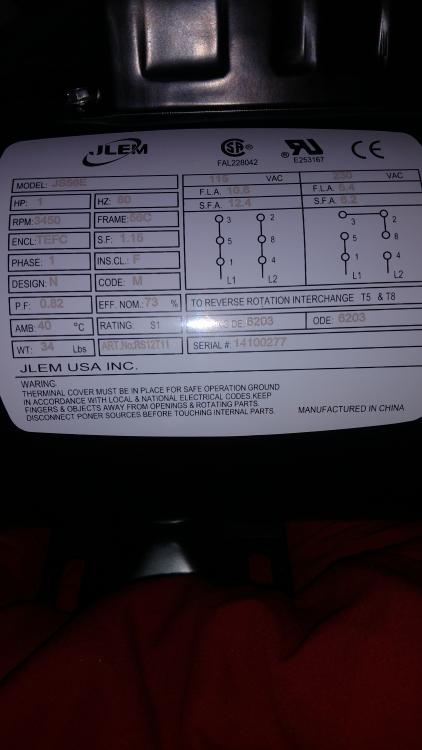

How do I need to wire my motor?

in Grinders, Sanders, etc

Posted

6 is a ground I believe and im not sure what 7 does.