bryson489

Members-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by bryson489

-

More experimenting with low layer pattern welding

bryson489 replied to MilwaukeeJon's topic in Knife Making

Great knife! I like that design alot! Gonna have to give it a try. It's cool when you get those little surprise faces or figures. I had a recent one that made me think of a snake. -

Yeah i believe they said the winds were in the 80-90 range and that's pretty uncommon around here, unless there's a tornado.... currently waiting on them to come do their assessment. Im more concerned more with the house, i prob won't get much for the shop

-

Yeah def more anchoring. It wasn't open before it rolled. The front wall were doors that opened so i could have more floorspace.

-

Yeah. It could've been a whole lot worse. at least the chimney stayed pretty straight Haha. Crazy that my shop got knocked over, couple trees down, shingles from the house everywhere, yet my grill (which always gets knocked over in a bad storm) barely budged.

-

-

Beautiful knife! So clean!

-

What did you do in the shop today?

bryson489 replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks guys, i had fun making it. I really like the pull ring on the hook side idea. Thanks! -

What did you do in the shop today?

bryson489 replied to Mark Ling's topic in Blacksmithing, General Discussion

Decided to give a try at a small grappling hook for the kayak when fishing. Some spots on the river have a smooth bedrock bottom, so i wanted something i can hook onto the roots protruding from the shores. Def a good learning experience for the next. -

That's pretty much what i was beginning to think. The stubborn part of me knows it has to work, so i keep giving it a try with the 5160. But it's getting old making paper weights ( I know, every mistake is a learning experience).

-

Ive been on the path of trying to make tomahawks and hatchets lately. This is the 5th attempt. I don't have very much luck getting a good weld though. Each time i try finishing it a bit further and cleaning up alot more before the weld up. It always starts out good but starts coming apart during final shaping. The wrap is mild steel and the core is 5160, and the handle a piece of diamond willow that had the right bend in it. It'll be getting thoroughly tested during the memorial day camping trip.

-

That's a beautiful pattern! Was the guard a random cutoff, or was it a cutoff from one of the steps on this blade?

-

Ive been itching to have a go at a feather pattern. And i definitely won't be doing many more till i can get some power. Haha. Started with 13 layers of 1095 and 15n20. Built it up to the 500 layer range. Lost alot of material with that. I ended up sandwiching a 1095 core in there to be able to get a decent sized knife. Im still fighting with keeping my billets centered when hammering but i'm getting better. The handle is some honey horn with g10 spacers and copper pins. I wish the pattern was more even from side to side, but i'm still happy with it.

-

Show me your Bottle Openers!

bryson489 replied to Arbalist's topic in Blacksmithing, General Discussion

Thanks grump, They're definitely a great gift for all occasions. That one was a last minute addition to a gift box and now i need about a dozen more now haha. -

Show me your Bottle Openers!

bryson489 replied to Arbalist's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

bryson489 replied to Mark Ling's topic in Blacksmithing, General Discussion

Got a little time to try a new leaf style today. It's cool how a simple fold completely changes the look. -

Amazing knife! Very clean design. And the sheath is equally finely crafted.

-

Im finally getting around to posting some pics of the finished product. I made another one from the little bit left over from this billet. Drew it out, twisted, and stacked it the same way, with one of the remaining twist from the original stack.

-

Finally got to start digging around in a couple of the buildings on an old farm down the road. Came across a nice 6" vice on a bench in the corner. And grabbed a wheelbarrow full of scrap. Couldnt pass up the old jack either, something about it being gear driven really stuck out. I'll come up with a use for it one day.....

-

Getting the handle finished up. It's always somewhat a bummer to cover some of the design with scales.

-

When your buddy welded the stack together for you, did he grind the surface of each peice ground clean? I noticed when i first started if i skimped on the cleanup it definitely showed later on.

-

Thanks alot guys. Just got it heat treated. I'll put some new pics up once i get it further along.

-

I started out with 11 layers of alternating 5n20 and 1095, drawn out, and twisted. Restacked them 5 high with a peice of 1095 in between each layer. This is the first time I've drawn out a billet to expose the layers like this. Next time i'd like to try adding twists in alternating directions, but I'm happy with the outcome.

-

Yeah, Frosty beat me to it. Amazing design on in the blade and all together.

-

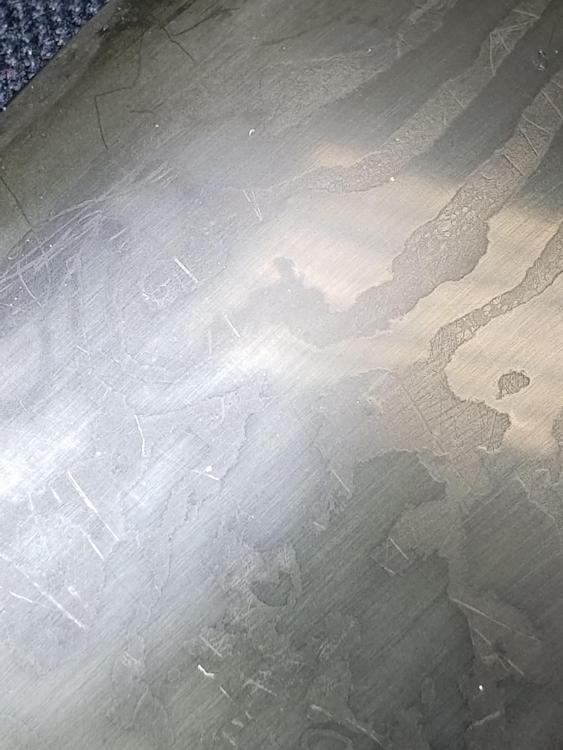

I put this blade together mostly out of some scrap from work so i can't get very technical. I put a stack together of some bandsaw blade and pallet strapping. I only went up to about 40 layers then i cut it in half and restacked it with a peice of 5160 as a core. I don't think i ever let it get cool enough when i was hammering, but with mystery steel i can't be positive. I use a coal forge for welding. I was very happy with the quench. First shot, no tinks heard, and the file skated across nicely. After finishing the blade up i etched it in coffee. This was my first time etching in coffee and i let it sit overnight. I wanted it darker still so i ended up leaving it in for the rest of the day. After the soak i noticed all these little lines. They look like cracks but im not 100% they only pass through the darker layers, and on the 5160. I can't find any on the bandsaw blade layers. It's hard to get pictures of them. Ive tried chopping into some logs to get it to break or make them larger but so far it's holding up. Just not sure if i should continue our scrap it. I don't see how it could be a result from the etch. I feel it should have broken with the amount of beating I've been putting it through if it was cracked. Oh, and i can only see them on one side of the blade. Any pointers would be greatly appreciated.