-

Posts

67 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Argentina

-

Interests

Smithing and Computers.

Recent Profile Visitors

1,906 profile views

-

I know this is an old topic, but I will post it here anyways, since this is a Sticky post with the most useful info: The book "Mokume Gane: A Comprehensive Study" has recently (last year) been released for free by the author, in this site: https://www.mokume.com/mokume-gane-a-comprehensive-study/table-of-contents Maybe everyone already knew, but still I think it's useful to have all the info in the same place!

-

I can't help by directly answering your question, but I would strongly recommend that you try to get a copy of "The Pattern Welded Blade: Artistry in Iron", by Jim Hrisoulas. I'm sure there are lots of other books on the subject availabe in your local library, maybe you can ILL some, if not.

-

From the photos it seems that it's ok, but just in case: Is there a big gap between the burner and the forge? If there is, exhaust gases (with no oxygen to light the flame) might be going up and getting into the intake.

-

In my humble opinion: You already have a fine anvil, which is the hardest part for most. So why not light a fire and hit some metal? At least to try it, even if it's only once. It might light the fire in you. Just about any hammer, some coal or charcoal, and some (non galvanized) metal is all it takes. Taking over a long held family tradition can be very rewarding on itself!

-

Welcome! As someone who thoroughly enjoys playing with sound, after losing a tiny bit of my hearing to loud music in my teenager days (not really noticeable in normal situations, but slightly annoying sometimes and worrying when thinking that it only gets worse), I will strongly suggest wearing ear muffs or whatever hearing protection you find most comfortable!

-

This seems like an interesting topic. I look forward to seeing your results!

-

Need help identifying this coil spring

AnBello replied to cedarghost's topic in Blacksmithing, General Discussion

Russian spring coils? -

Need help identifying this coil spring

AnBello replied to cedarghost's topic in Blacksmithing, General Discussion

It looks really similar to a piece I picked up from train remains (in a legal way). I only have about 1 full turn, but it looks practically the same, so it might be related to something Train-like. About annealing: That is only useful if you will be working it cold. If you are forging it, annealing does nothing (as all heat treating effects go away at forging temps). Just make sure you are hitting it while it's hot enough. -

In my own personal opinion, I would go for a wooden handle, because I believe it would most likely feel too heavy on the back if not. I think there is a reason why metal handled knives aren't very common (although sometimes going against what is common has its merits). I would also like to know more about the knife itself. What will be it used for? What steel is it?

-

There are lots of ideas here on this forum , but I can recommend a few things that might give you ideas, based on what I've seen here. You can make something for the kitchen, some easy tools (punches, hot cuts), wall hooks, or some bottle openers. Ornamental stuff will teach you a lot, will be hard to do, but will not be as critical as a "tool" if it fails. Do you have a partner or a close family member with a hobby? Make a gift related to that, for example a miniature golf club or baseball bat, or a set of dice. Flowers can be difficult, but leaves and vines are more forgiving maybe, so there are stuff for gardeners as well. If you can't think of doing anything for yourself, do something for another person!

-

Another rail road iron anvil

AnBello replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

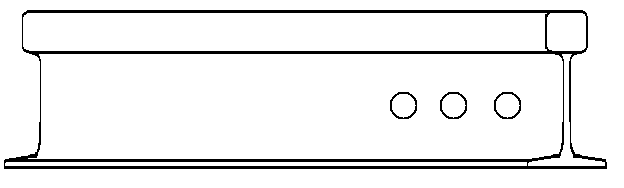

I appreciate you revived this thread. I had read it a few years ago, but had forgotten entirely about it until now, and I was already thinking of what extras I could add to my rail. So far it's on end, and I was thinking of a hot cut and a fuller, but it will be some time before I make a final decision. Seeing this brings me some more inspiration! The piece of Rail that I have has 3 holes close to one end, and I'm thinking that they could come in handy for some things. I don't have any measurements right now, but here is a drawing. I'd really like to hear ideas on what they could be used for! -

Welcome to the forum! I also really like computers and the internet. I even work repairing PCs in my free time, and build PCs for my friends whenever I have the chance. I play lots of games, and have spent lots of money on my PC. I can tell you that this place is one of the best sources of RELIABLE information you will find on the subject of blacksmithing. There are some people that make their armour and maille, and a lot of VERY knowledgeable people in these subjects and many others. Also, let me tell you that here, your own effort is greatly appreciated. That means, you should always try to search for information and do your research before asking. A LOT of questions have already been answered in great detail. I strongly advise that you read the "stickies" in the topics that are of your interest (those posts in the top that have a green pin on the left). Here you will find a lot more info, this is a great post by JHCC that explains many things a newcomer should know. Now, let me tell you something else. I may or may not have (it's difficult to get a diagnose for several reasons) a slight autistic spectrum disorder as well (related to Asperger's), so I will give you a very small piece of advise out of my limited time in this forum. (I know, ASDs come in many flavours, so it might not apply to you at all. But just in case) This forum has a special dynamic, which is one of its greatest features, but might be shocking at first. People here are honest. Respect is very important, but this is not like a meeting with lots of strangers where unconditional cordiality goes above everything else, even above the truth. This is a lot more like a family gathering, where if someone were to do something stupid, they will tell you so, in a direct and blunt way most of the times. (You can always ask something stupid and that's perfectly fine, just try not to ask the same stupid thing that has been asked 50 times before and answered in great detail in the stickies) But, if you show you are making an effort and doing your own research before asking, you will see this is one of the warmest and friendliest places around, and an irreplaceable source of information! (And also, jokes and puns are very common, so you will have to pay attention to know when the post is actually a joke and not to be taken literally. They are usually short , 1-line posts)

-

In my opinion, the best way to determine this is "conservation of volume" (as long as we dismiss the metal you lose to scaling). Before drawing out, and after, you have the same amount of metal. The same volume. You start with 1" x 3/4" x 6-1/2" = 4 7/8 cubic inches, which is the same volume you have at the end. So: 4 7/8 cu.in. = 1/2" x 1'' x ??? => Dividing, you get ??? = 4 7/8 divided by (1/2 x 1), which in this case equals 9 3/4'' EDIT: Well, WMG jsut beat me to it by a few seconds.

-

I'm really interested in seeing more ideas and projects for the kitchen. I remember seeing a RR spike spatula some time ago (and some eggs or pancakes made with it) which I also liked quite a lot (and my GF has been asking for one like that ever since).

-

Maybe you even end up with temper colour(s) on top of the pattern. If it doesn't work, just redo the etch. I'd much rather have to redo the etch than lose this awesome blade to some failure!