BartW

Members-

Posts

281 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BartW

-

Hello; Practical problem here; I need a 25 cm (10 inch) diameter hole in the ground, more than a meter deep. Now I don't have one, and I can't buy one (lockdown & self-isolating). But I have a LOT of iron and steel and a lot of tooling to manipulate them. I know of three types; First is the typical "auger" style thing; resembling a helical drill, often made by round things welded to a central round thing. Then there is the 2 bar type, which twists at the tip. Then there's the pipe style thing with dirt-scooping points below (this one is often quoted for rocky soil). Now I don't have rocky soil; but I do have LOTS of roots, as I basically live in a forest. I also have 25 cm diameter diving bottles which I can cut up; which would make the last option probably the quickest. What do you recommend ? anyone know any "hack" to make the helical flights for a soil drill ? greets, bart

-

From Belgium here, we just installed 4 gasoline powered screw compressors & backups from the fire-departement in a hospital to build more respirator capacity. They probably don't have enough oxygen concentrators for hundreds of people, but they will at least be able to artificially breath for them. I donated most of my oxygen gear (diving instructor), and gave them all my pneumatic valves, solenoids, hoses and such as there were a couple pneumatic engineers there upgrading the respiratory support system. This hospital is special in the sense that it doesn't have CPAP or respiratory boxes per intensive care bed, it has plugs and valves per bed with a centralized compressors and oxygen units. Which means they can support a LOT more people needing this kind of support. What was a true eye-opener for me, and proof that this beast isn't the flue, is the exhaustion of the people in intensive care. In a soaking wet bed. Lots of young healthy people too. I talked with someone who recovered (from behind a window). 26 years old, 40 % lungcapacity left. He is going to leave the hospital with an 80-year old chainsmokers lungs. He spent days in a haze from fatigue, like an elephant stood on his chest, trying to breathe, but only achieving partial breaths, feeling like every next breath could be his last. He fought through it although he considered giving up a lot too, but then he realized it would be a miserable way to go. Our goverment has shut schools, everybody is to self-isolate, only stores opened are those selling food, and go out only when needed. Most people follow this fairly well; but you still rarely see facemasks in stores' clients. I expect these measures to continue to June. (So the whole april & may ). My blood curdles when I heard [someone] say the cure is worse than the sickness, I suggest he takes a visit in an hospital with some patients in intensive care. So my 2 cents; Protect yourself & your loved ones from this. PPE when in public, walk away when you see too much people together, or people without facemasks. Isolate as much as possible.Teach your kids clean routine. Do not underestimate this, but don't go into panic either. Consider everything you cannot vouch for as "clean" contaminated. This beast doesn't care about your age, $'s, colour or location. It's a lottery. 75 % of the people will be mild. 25 % will be sick. Some will need hospitalisation, and few will die. (Don't quote me on those numbers) Care for others. I've given away most of my shop facemasks (I used to buy them by the 100, the N95 rated dustmasks). There's a time and a place for everything. Now is the time to NOT get this, mourning & comforting others can be done later. There's a vicious thing going on in the (mostly financial) economy right now; abusing this situation. Please stop that, as it will get a LOT of people dead and even more suffering.

-

What files (and/or tools) do you swear by?

BartW replied to DamianSilas's topic in Tools, general discussion

It depends on your location in the world a lot i'd say. Öberg, Sandvik, Bahco => Good scandinavian files Valor, Pferd, Grobet => Good European files I'm not that familiar with USA brand files, I suppose Nicholson, Black diamond ... one thing you need to learn is to store your files, and the restrict their usage to only one type of material. Wood and softer stuff = one file; Brass,bronze, copper = one file, steel, iron and stainless = one file. This makes your files last longer. Also, invest in a good File brush, and store them dry. mvg; Bart -

Hello Guys; I was given a box of 33, 35, 40 and 45 mm drills; mostly new, some chowdered up. MK3 and MK4 tapers. I can only use them in my lathe (MK3 tailstock). I have nothing with MK4. And the bucket contains 50 drills. I always assumed these were HSS; or M2 tool steel; and as such brittle and not suitable for hammering. Then I found one with a chowdered up tip, but what struck me is that the taper had some dents. Like someone hammering on it. The "drill" end of this thing is really hard and will readily chip if struck; but the taper part is soft. So I figured, lets give this a try, I cut it up and made a cute round drift. Guess what; it actually holds up pretty good, and the top even mushrooms (without splitering or cracking). It behaves like 52100 or 9260, it doesn't move much under the hammer at all, but being a drift and being already in that shape, it doesn't need to either. So I'm puzzeled .. the drill end is most defenitely HSS (it's written on the drill, manufacturer: cleveland) , but the taper part, is that still HSS ? Somebody is probably going to tell me this is a bad idea - and I agree, I was expecting to be attaching pictures of shards of steel and a cracked drift, but nope. So.. altough this is probably a bad idea, why does making round drifts from the taper part of huge drills actually work? greetings, Bart

-

Hello All; Coming from a large steel plant where the make mostly sheeth metal from recycled steel, they dropped off 3 bars of this weird block of steel. Each bar is about 3 m long and weighs a ridiculous amount. 10 cm or 4 inch square with a groove on one side. I'm cutting them up in the driveway where they dropped them off All sides are machined , but only one side is hardened - the side under the ruler (looks like case hardening). Bandsaw cannot cut through the last half cm (about 1/4 inch). Every 15 cm, there's a M20 metric blind screw hole on one side about halfway in the block. The groove cut into the bar is 80 degrees (looks like 90 but it isn't, I measured it). I chopped one bar up in 10 x 30 cm pieces, and fixed two together, and had some beginners whale on it because he wanted to make a hammer. There's am M20 threaded rod in the center, so they are screwed together; then welded. Flat surface is 20 x 30 cm, the hardened surfaces (one top, one bottom) are 10 x 30 cm if you stand them on the side . We radiussed the sides to different radii. total weight is about 40 kilo's or 90 pounds Now what is the idea of this thing? The same beginner said that the hardened sides make a nice anvil; the grooved and flat side make a nice swage block. Given that he's into making spears, I can see where he'd like the large grooves. After some pondering; we milled in a small 12mm square hole on this one, the next ones have a 25 mm square hole , and a large hole for hammers and axes, and drilled a 8, a 25mm and a 30 mm hole. I can't drill the hardened sides. We made 5 of 'm, and I gave 'm all 5 away, people seem to like it as a anvil shaped object, but also as a swage block. I got 10 more lying in the garage in pieces But does anyone have any idea what these things actually were ? The not-hardened part is relatively soft, but it's not as soft as mild steel. Second question; How would you mount this ? I suppose you could make a low stand and use it like a swage block because I never need the hardened sides as an anvil. But what kind of stand would you build for this if you were a 16 year old lost soul trying to get into forging without any money, and a weird hermit nutcase gave you this to get started in forging ? If you wanted to use it as an anvil, you'd need to fix it down, and the holes and groove would become useless.... greetings, Bart

-

Possibly Pine Anvil Stand

BartW replied to Drunken Dwarf's topic in Stands for Anvils, Swage Blocks, etc

Hello All; Yup, I live in the EU, and yup, they banned borates. reference here: EU law banned borates without exception It's about tooth whitening cosmetic use, and the dentists wanted it banned I guess to have more customers. The fact that Borax is almost entirely USA-produced Probably has something to do with it too Anyhow, there still are sources for borax, most notably ceramic supplies, or metal casting hobby shops. They will run out sooner or later, but since pure borax has a unlimited shelf life and is dirt-cheap, they usually store a lot. Borax prices have also increased, probably caused by it. I don't believe for a second it has negative fertility effects; besides the fact that borax is used in forgings and castings, but are typically somewhat dangerous. If you've had a legvise handle in your groin once, you'll know how bad for your fertility forging actually is. Nothing to do with borax. Anyhow; I've stocked up on 100 pounds of borax, which will last a couple dozen of lifetimes given my current usage. -

Wel actually We know how it was created. it's impregrated beech laminates with clear epoxy under high pressure and temperature. Made in the UK somewhere; and they are called epoxy welding plates :-) And when grinding them, they actually smells like epoxy; which is much more pleasant then working micarta. And it doesn't crumble or chip, but acts more like micarta. My mill eats it for breakfast.

-

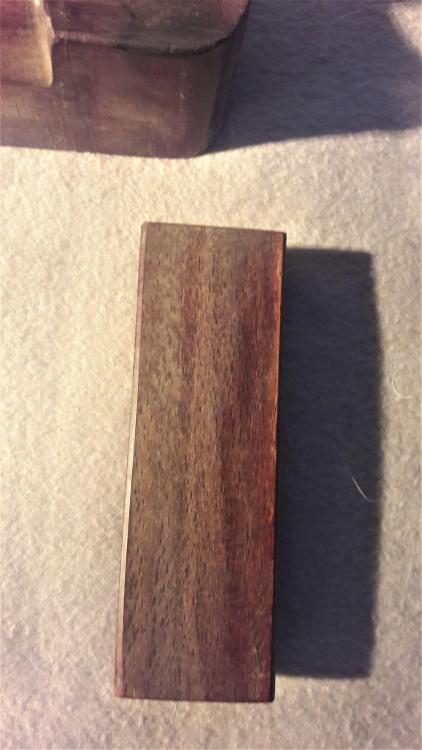

Hello Guys; Warning; picture heavy ! As you know, I have quite a few friends in the railway company (I don't work there). And I found some intresting material for knife handles, that is very reminescent of pakkawood or dymondwood. They used to use it for connecting two sections of track together isolated electrically. They are huge chuncks of 2 foot long 4 inch by 2 inch blocks, painted black. I cleaned one up, cut some blocks and fitted some knives with it, and I like the material. Doesn't stink like micarta, machines like micarta, and looks like wood, but is absolutely impervious to oil, water, temperature changes ... And the best part; they got tons of these, and they all need to be trown away because they are switching to some tougher synthetic electrically isolating thing (with is essentially a block white-greenish fibreglass, which is not fun to work with :-) ). Anyway; pictures tell more. First is a stack of 6 of these plates; with some cut off parts and cleaned up sections.; then some details of the material under the black paint when cleaned, then some knife handles. enjoy & what do you think of this stuff ? It's obviously pakkewood or dymondwood of sorts, but with beech layers.

-

Is it me or does that Vulcan look "modified" ? Like someone trying to re-weld a face plate to it ? There's too much room between the logo and the top, and the sides are way too clean. Even the top of the logo has grind marks, and the hardy hole looks like it has been filed. I'd take the other one.

-

I've run across a couple of springs that don't harden at all, not even in water. It's also probably a location thing.. in the USA most leaf springs are some form of 5160; but in Europe for instance there's a whole slew of steels used to make springs. I've found C70; C80, C90, 9260, 5160 in springs, but also stranger stuff that simply doesn't harden at all.

-

Nice video, and the box repair part was pretty much what I had in mind. Except one thing ... I just checked my other (normal) vises; and they use trapezoidal thread but size TR24 (about 1 inch) or TR30 (I have both on supply with nuts) ; While my post vises use TR40 (like the one in the picture); I even found one that uses TR44 (almost 2 inch). Why does it has to be that heavy ? Those normal vises can squeeze fairly hard, and really the limiting factor is the human using it. What if I replace it with basic TR30 trapezoidal threaded rod with matching nut ? I'd have less work, no purchases; but I wonder why they'd use threaded rod that heavy. Especially if you are going to braze on the thread in the box; I'm fairly sure the precision machined TR30 threaded rods and nuts from medium hardened tool steel are FAR stronger, even tough they have a smaller diameter The amount of rotations needed / travel distance is almost the same. If I had to use allthread for the pivot; I would have made a threaded sleeve to go over it to serve as pivot point out of bronze or brass. Unprotected threaded rod as a pivot will wear out fairly quick.

-

I had a box of 'm tested (these were 20 and 25 mm hex keys), and they turned out to be basic C50 steel. Al in all, I consider them mostly all simple carbon steel.

-

Hello Guys; I revieved this tiny (well small compared to the other ones ) post vise, but it's in need of repairs. It needs a new spring, but that's easy. And I wanted to make it a low free standing vise, since every other vise I have it much higher. The spindle and the box is of more concern to me. I'll attach a picture of the trapezoidal thread spindle. Having measured it; it's standard TR40 x 7. (40 mm outer diameter, 31 mm inner diameter, 7mm thread ) That's good news, I should be able to make something like that. What bothers me more is the quality. When I was removing grease from the box, I took 2 or three piece of thread out. Simply broken of inside the box. As you can see in the picture, the first 10 cm of thread is severly worn down. Now the question is fairly simple. Is this damaged enough for you to replace it ? I can replace it - costs me about 100 €, just put a new threaded rod TR40 x 7 in the handle and weld it solid; chop of the part of the box the size of the fitting nut, and weld that on. But it will take me a lot of time at the lathe, and it still works as-is.

-

Hello, I was wondering, could you make a tripod style anvil stand for a 242 pound anvil, with traintrack for legs and a really really heavy plate ? I know, it would get really heavy, but it isn't a movable stand anyways, and I have a crane to move it around. bad idea given that it's hard steel and not plain mild steel ? mvg; bart

-

Hello; I actually use this vise most of the time. It's much sturdier to bend and twist stuff (even cold), it servers as a swage block to make hammer or axe eyes ... If I only had machinist vises, it probably would have been killed already. People hit whatever that Vise is holding with sledgehammers ...

-

Gorgeous anvil. Use it well. I have 2 skoda's, and I find their steel quality is exceptional (HRC 60 or more) , even compared to Refflinghaus or peddinghaus, and I absolutely love them. pictures are here: skoda anvil twins

-

French or Belgian Anvil?

BartW replied to JackCambodia's topic in Anvils, Swage Blocks, and Mandrels

Doesn't look like a UAT. I have one, check my posts. UAT's usually don't have a side-exit of the hardie hole. Those are mostly french. There was a post about UAT anvils finding their way to Argentina. mvg; Bart -

Sanding in general is bad, as it removes material from an already thin faceplate, so in general, don't do it. Wire wheeling, is OK for cleanup. I don't get why the braided/knotted wires would cause an issue over normal wires ... I find normal wires to be "floppy" and "softer", but the material removal rate is the same as for braided/knotted wire ... For mounting; please check this one - especially the video in it, and listen-. 2 identical cast tool steel modern anvils. one secured with straps, one glued down to the stump. https://www.iforgeiron.com/topic/61423-glue-to-hold-an-anvil-down/ Oak is fine for a stand, just make it absobutely seamless (or fill it with glue :D) and make sure it resonates as "one" object, not as two seperate objects (anvil & stand). This is why bolting it down securely is so helpfull in reducing the noise.

-

Amen to that; lots of info in your post. I have 2 czech anvils, solid cast tool steel from naval gun castings, and one Belgian anvil with a 1,5 inch faceplate. And they used to make hammers from C80 (Railroad track in Belgium), and water hardened them to HRC 60'ies.

-

Hey Hans; I got another piece of your UAT collection https://www.iforgeiron.com/topic/63786-anvil-saved-from-the-trash-with-a-crack/ Just kidding, Nice score man. I love these anvils for 2 reasons. 1. They are extremely tough & hard, bordering indestructible. 2. They are made in Belgium, just like me.

-

I melt my flux (borax) - including the used flux - untill it's a castable solid, and I pulverize / grind the block, then go through the powder with a large magnet. After a couple recyclings it becomes a nice gray powder.

-

Actually, if it's a clean certified & tested propane tank, as soon as you removed the valves (and the interior was in fact exposed to the outside) all the propane will be gone in minutes. However, I have never found a old propane tank that was clean on the inside; and that's the danger. Most of the time there's at least some oil in it, which can dissolve propane and be explosive. This is why people tell you to fill it with water first. This will also remove some dissolved gas from the crud and the rust inside too. Sometimes there's wax in there to protect the inside against corrosion. This is why people tell you to mix in soap. If you start mixing in acetylene bottles, the story becomes even more complex, as these bottles contains a light rock and the acetylene is dissolved in acetone. DO NEVER OPEN THOSE. Spent petrol or diesel tanks ... Never cut these open either. Bottom line: Removing valves = absolutely the most important. Filling with water is the best idea. Filling with soap water is even better. Letting is sit outside for a longer period is also good. However, i've learned never to trust gas bottles, and as such i'll never use a plasma burner or cutting torch on them, I will use cutting disks, but I never empty the bottle. I usually just cut them open when they are still half full of water.

-

I've done a similar repair last year, with similar results, and even with a broken drill bit in one hole too. My fix was somewhat different though. I ground out the drill with a carbide endmill - very slowly , lots of coolant. But I never tapped the hole, I just cleaned it, degreased it, made new jaws that lined up perfectly, and made soft copper rivets; and hammered them in. The customer wasn't going to use it to hammer on anyways, and the copper rivets are still holding up strong ... And with the mangled thread on the inside, it's really stuck in there, but still easy to remove, it is soft copper afterall.

-

yeah got that problem too. I've got one dog which figured out how to open doors, including the door into my shop. In general I don't let dogs in, because there's always some sparks flying around or sharp metal chips on the floor. I really should clean my shop more ....