Michael Cochran

Members-

Posts

1,889 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Michael Cochran

-

Horizontal/Vert or Porta Bandsaw

Michael Cochran replied to Danjmath's topic in Saws, bandsaws, hack saws, etc

I thought about trying to find one of those fancy ones you set the blade down and let it cut off while you did something else but decided on a portable instead. I then decided to build a table so I can build jobs for repeatability for projects such as a split cross. I show pictures and made a description of what went into the build in the following thread. Maybe that’ll help a little with your decision. https://www.iforgeiron.com/topic/53269-portaband-table/ -

Easiest way (for me) to tell cast iron from steel is to try drilling it. Cast iron doesn’t send out curls like steel does, instead it’s more powdery looking.

-

That’s a good point. I was originally going to put it in the shop but since it’s not climate controlled it’s not a good place. I’ll keep it in the house by the wood stove instead.

-

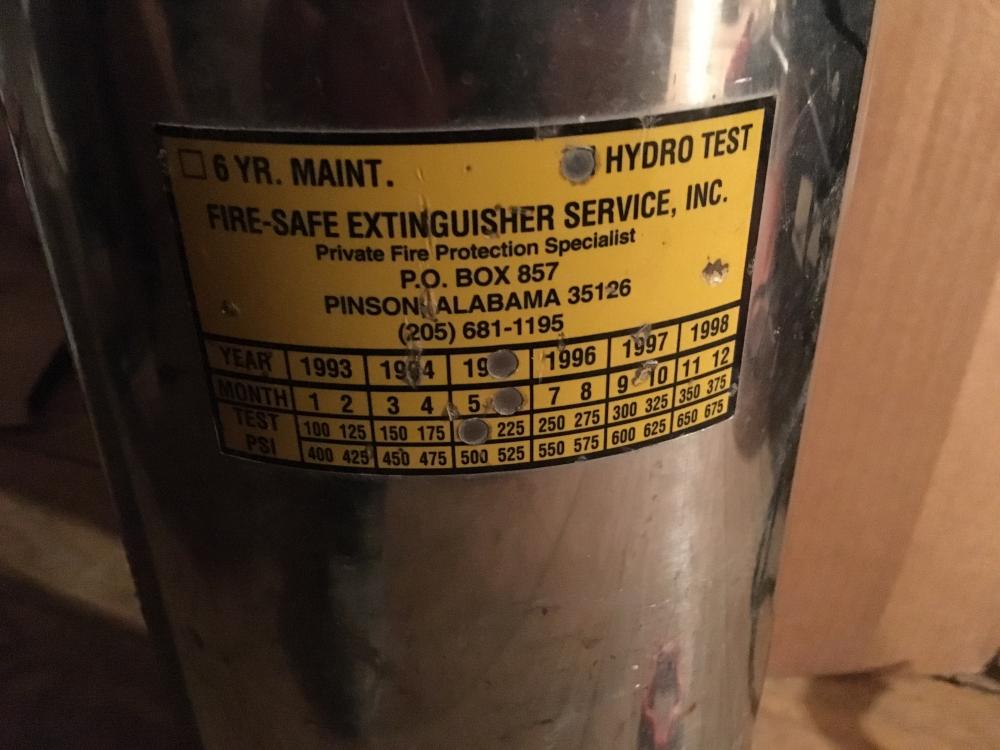

Reeltree, that’s what I assumed and verified when I got home yesterday. According to the attached sticker, I need to have it rechecked even though it feels and looks solid to me. Even though I payed $0 for this extinguisher I still wanna have it looked at. I’d hate to fill it and it blow up in some way. At least if I have it checked out and get it stickered I can have the peace of mind to know it wasn’t my fault. Daswulf, the cv joint came from some forklift at work (either a large outdoor one or a warehouse size). The rubber is blown on it and there’s is no grease left in it. I have another one that’s just the ball side that’s horribly disfigured and no longer a ball end lol. As far as the bucket teeth goes I have a couple ideas kickin around. JHCC, I had to look for a picture to see what you were talking about. That’s a cool idea and I might have to try that if I find some of those.

-

Today I got myself a new (to me) water can fire extinguisher. I know the basics of refilling but plan to get it checked out before i try to do it on my own. I have never used one of these, only dry chemical, and hope to never need it but I’m glad to have it just in case.

-

Appalachian power hammer motor problems

Michael Cochran replied to JIW597's topic in Power Hammers, Treadle Hammers, Olivers

Did you use plans to build this hammer or did you just guess based on pictures? If you used plans did you follow them as closely as possible? -

Norlund Style Axe Dimensions?

Michael Cochran replied to Steven Lancaster's topic in Axes, Hatchets, Hawks, Choppers, etc

If you go the .75” route you could always upset the end some to thicken it up to make sure the eye walls aren’t too thin. Please keep us informed and to how it goes. I know I might wanna try one sometime. -

Norlund Style Axe Dimensions?

Michael Cochran replied to Steven Lancaster's topic in Axes, Hatchets, Hawks, Choppers, etc

A piece of steel measuring 1x1.5x3” will come in a hair over the 1.25 lbs of the voyager axe. I’m not sure how big it’s supposed to be. You might wanna try 2” instead of 1.5”. -

Norlund Style Axe Dimensions?

Michael Cochran replied to Steven Lancaster's topic in Axes, Hatchets, Hawks, Choppers, etc

I can’t help much but when I looked to see what you’re asking about I see multiple styles. Which one are you wanting to know about? The different styles will need varying sizes of steel in order to make it look right. For example the voyager is smaller than the cabin axe meaning much less steel needed to make it than you would for the cabin axe. -

Josh's misguided musings in metal manipulation (Photo Heavy)

Michael Cochran replied to Josh Foran's topic in Member Projects

Josh the 6x6” will need to be cut down. It’s probably 10’ or so but I will cut it down for you to a size that’ll fit in the trunk of a car. Just tell me how long you want it. I might still have a short piece or 8x10” or 10x10” behind the shop if you think that would be better. -

Josh's misguided musings in metal manipulation (Photo Heavy)

Michael Cochran replied to Josh Foran's topic in Member Projects

Makes sense to me. It’ll be a while before I try anything like this again. Last time I did I had an American bulldog that found my hide I had drying and thought he had a new chew toy. He ruined a large deer cape a hunter friend gave me. -

Josh's misguided musings in metal manipulation (Photo Heavy)

Michael Cochran replied to Josh Foran's topic in Member Projects

Josh I have an old 6”x6” id be willing to part with. Just keep me in mind when you start making leather I plan to be at the meeting in Cullman in January so I can bring it with me if you’re going to be there. Jasent how long of a beam is a good length for deer hide? -

I love when maintenance at work starts “cleaning” their spaces out. I found a few things in the trash I could make use of but a couple items are gonna be boxed up and shipped out to another ‘smith. The shoe is a size 12 and the paper is a piece of legal printing paper for size reference. The black thing on the bottom left of the picture with the bolt is some kind of rubbery material about 1/16” thick and about 12”x55” (all estimates). Not sure what good it’ll be but I’m sure I’ll find something to do with it. The thing with the cord is a magnetic heater. I have a couple ideas what I could do with it.

-

It’s been mentioned on here several times about using coal from tractor supply for forging. I have used it myself and found it satisfactory in spite of it being less than ideal. I recently came up with a couple projects that would be better in a coal forge instead of my gasser so I started calling the local stores looking for a supply. I found one store that actually told me that as a company they will no longer be supplying coal. Even though it sold well in some locations corporate office decided it wasn’t making enough money company wide to make it worth continuing to offer it. That said if your local store sold it and you use it you might want to buy any they might have left in stock before it’s gone. I thought I’d share this new knowledge with everyone so we don’t keep telling people they can use coal from tractor supply.

-

Coal vs. Propane .

Michael Cochran replied to Krylok's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Gas forges have advantages over solid fuel in that the fire is usually cleaner, the heat is set it and forget it, you can have multiple irons in the fire with less risk of burning them, etc, etc. Of course with solid fuel you can more easily heat a spot instead of the whole piece. You’re able to heat pieces that are large or irregular in shape. The list can go on. It depends on what you need and prefer to use. I have and use both depending on what the project at hand needs. -

I felt bad last night not making it to the funeral home and felt worse today. Only two people from work showed up. It’s sad that only one from his department showed up . I heard he will return to work Tuesday but can’t blame him if he takes a couple more days.

-

Today as I was leaving work there was a note on the timeclock about one of the department supervisors wife having passed. She’s been sick for some time (well over a year) but I hadn’t heard about anything changing until today. I don’t know what it is about this time of year but it seems like it happens ever year when it starts getting good and cold. It’s sad it’s so close to the holidays and there are so many out there in the world losing loved ones. Let’s all take time to enjoy our friends and family and remember all those who’ve lost someone recently.

-

Your whole family is on the list.

-

Anvil guess?

Michael Cochran replied to Timber Ridge Forge's topic in Anvils, Swage Blocks, and Mandrels

How long (heel to horn) is the anvil? The picture is deceiving me because it definitely doesn’t look 11 feet tall or 24.5 inches across the face. -

What did you do in the shop today?

Michael Cochran replied to Mark Ling's topic in Blacksmithing, General Discussion

I didn’t see it at first either but, unless my eyes are playing tricks on me, it looks like it’s large angle iron cross sections. Looking at the picture you included in your quote you can see the buldge (web?) in the corner of the angle in the top right and bottom left corners of the frame. I definitly might have to give a couple of those frames a try myself as I have some larger angle sitting idle asking to be used. -

Rusty/Dusty flywheel?

Michael Cochran replied to Jason Fry's topic in Power Hammers, Treadle Hammers, Olivers

Thank you for sharing all that, Krush. I look forward to coming back and re-reading that as I get closer to putting my krusty style scrap hammer together. -

Rusty/Dusty flywheel?

Michael Cochran replied to Jason Fry's topic in Power Hammers, Treadle Hammers, Olivers

Krishna, I’m sure there are several people that might be interested in what you have to share, myself included. -

She’s worked pretty much her whole adult life in the nursing home industry and has had to deal with plenty of death as a result. This one was different the way I understand it. I know I have loads of respect for anyone who can do what she does. I know I couldn’t go to work every day and take care of and get attached to people like she does, like all the good ones do. I’d shut down emotionally after losing a few, she’s built much stronger emotionally than I.

-

By chance are you talking about the bicycle wheel hooked up to a leaf blower? That could be a simple enough project. With a little trial and error I’d imagine you could get one working but you’ll probably have too much air supply if you aren’t careful.