-

Posts

201 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by DuEulear

-

I am a fan of norton belts if you hold out and buy ceramic belts you will find they last long enough and the increased speed of cutting make them cheaper in the long run https://trugrit.com/index.php?main_page=index&cPath=198_1_145_157&zenid=48df471984ceca993a05dc8478944a2e This company has good prices and service they also have price breaks for bulk orders starting at 10+ belts du

-

I live in charlotte mi i purchased my last 6” vice from a guy in gr for 75 $ in working order i would say 75-150$ if they know what they have and less if the seller is not into tools or it be broken du

-

Knife won't harden.

DuEulear replied to Conrad.blacksmithing's topic in Heat Treating Knives, Blades etc

From what you say you diffretially heat treated the blade when you quenched the edge only before cooling the whole knife if this is true then the spine of the blade should be soft while the edge is hard du -

Meant for blacksmithing?

DuEulear replied to Strangecacti's topic in Tools, ID, and pictorial reference

A blacksmith? -

Mixing Oxyacetylene in the same cylinder

DuEulear replied to onetreeforge's topic in Safety discussions

Jhcc They are perfectly safe if used and matained correctley. And very useful when you need localised heat quick. writing off the use of a tool because it is dangerous if used improperly pretty much excludes you from this hoby as all our tools will hurt you if you do not understand and mittigate the risks. du -

Mixing Oxyacetylene in the same cylinder

DuEulear replied to onetreeforge's topic in Safety discussions

Heck acetalene under pressure in a tank without oxygen is a shock sensitive explosive. That is why acetalene tanks have the pumice and acitone in them to stabilize it for transport. Which is also why we dont tip tanks for transport or draw too much volume too fast from a acetalyne tank putting both in the same bottle under pressure is suicide. I hope he did not manage any sales before he went boom du -

New Ridgid #165 or old PW #240 - which one?

DuEulear replied to Rojo Pedro's topic in Anvils, Swage Blocks, and Mandrels

I have had my rigid 275# for 10 years and love it depending on where you are it might save you cash on shipping to special order through homedepot as you will be able to pick it up at the store for the sale price good luck -

Seeing as you are forging a (drop forged wrench) you have a piece of unknown tool steel most tool steel alloys have spacific tempature ranges they need to be forged at or they may crack, suffer from excess grain growth ...... wothout knowing the alloy involved it is hard to say if you worked it too hot or too cold. Hammering scale into the surface makes it ugly but dosent usally lead to cracking( but it could in theroy) if you are a beginner and you really want to make a knife i would suggest working with a source of known toolsteel. 10xx sieries is more forgiving than most as is 5160 small bars of both can be found realatively cheap. du

-

Welding on an S7 Face Plate

DuEulear replied to bajajoaquin's topic in Repairing and Modification to Anvils

I am with jim on this one it is possible to acomplish what you say but if you factor in your time and costs it would be better spent making something to sell to raise the funds you need for the new anvil -

Seeking advice for my begginings

DuEulear replied to Goolsby7's topic in Blacksmithing, General Discussion

If you are far enough out of town to have a retort and not anger all the neibors with the smoke you can also build a old fasiond charcoal mound Craigslist is where i find barrels when i meed them usually for 10-20$ each -

What weird animals have been in your shop

DuEulear replied to Glenn's topic in Blacksmithing, General Discussion

When i was yonger i trapped coon in michigan for furs and food the first coon i trapped was a 42 lb female after 1/2 a mile dragging her out i thought i was deer hunting -

"I want to start blacksmithing"

DuEulear replied to Marc1's topic in Blacksmithing, General Discussion

I tend to believe that knives hold a facination for people as the possesstion of a cutting edge is seen by many as the first tool of mankind. They often forget that without a hammer (however crude a)stone knife cannot be made, and without an anvil (however improvised) it cannot be made eficiantly. this means the cutting edge is the third tool of mankind not the first but it still gets all the credit ...... why? Because it is sleek deadly refined perfected ...... obviousley shaped by hand. I think people forget that before we had powertools for evrything we had handtools that where almost as fast and evry bit as precise in the hands of a master craftsman. The knife is the only handtool that dose not have a power analog. And i would venture to say evrybody has handled or used at least once in thier lives. conciquently we forget all the other cool stuff the iron age brought us and give the knife all the credit. Du -

You could be seing the actual crystal matrix of the steel itself. However this might point to a grain growth issue ? I wouldent think you should be able to see crystal boundaries with the naked eye at 320 grit. But i have never cryo tempered a blade eaither keep us posted i would love to se how it turnes out du

-

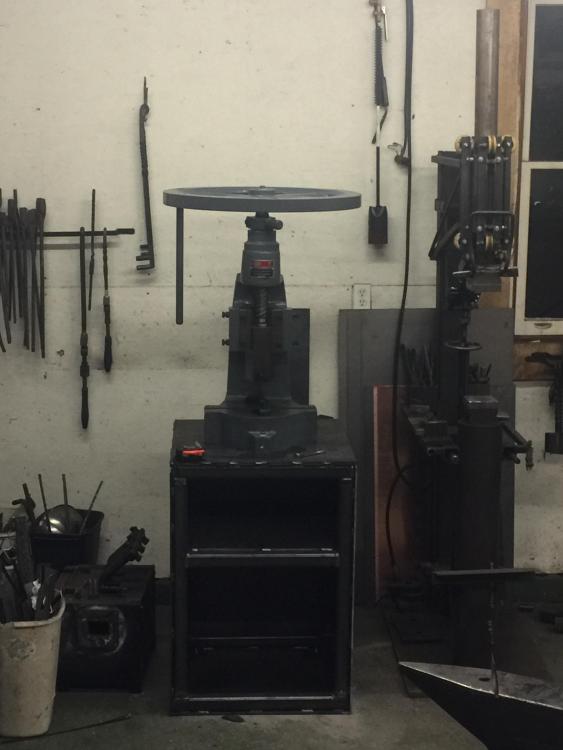

Well a buddy found this for me and for 50$ i couldent resist now i just need the rest of the parts for a h press

-

I need some help, metallurgy class was long ago...

DuEulear replied to t2harh's topic in Blacksmithing, General Discussion

Seemees like 4140 heattreat would be the most likely to fit the bill as it is pre hardened and tempered to 25-35 hrc if you need a greater level of hardness you will most likely need to do a heattreat of some kind if so try an air hardening alloy like A2 and take a camping trip or find a buddy with a hairdryer and a bbq. enjoy du -

Steel size when beginning a knife

DuEulear replied to MikeTausig's topic in Knife making Class General Class Discussion

Personally i start with 1/4 flat bar and forge to shape this is only because it is the thinnest barstock sold by my employer on the grades of toolsteel i work in. ( that i putchase at a discount) forging dose allow us to make our parent bar out of almost anything. Some toolsteel only comes in rounds from my supplier so i will forge to a size i need from round. i caint offer any ruel or math on the subject other than start size should probably be around 110-120% of your desired finished size ( forged ) by volume. This should give plenty allowence for grinding. Du -

Looks great nice clean work on the knife overall and a good grind too keep up the good work

-

Tool steel blocks possible anvil

DuEulear replied to Guns 71's topic in Anvils, Swage Blocks, and Mandrels

If the two halves fit togeather tight like tgey shoud i would be inclined to stich weld them togeather with whatever rod i had but use a pre heat and post heat as doc is right welding toolsteel is an adventure but i have had good luck with non critical welds in places that wont hurt if they ( when they fail) i would not bother unless this gave me a bigger work surface otherwise i would just stand her on end and get to work du -

Thanks but i have seen alec’s shop he has more toys than me tis true i have come a long way in 11 years

-

-

Both are verry good looking and i would be proud to have paid fair market to wear one on my hip. If the file check is good and you dont have any cracks and she holds an edge it musta been somthing good now where do i order more... Scrap steel is fine for knives as long as you don’t mind playing the heat treat guessing game with evry new bar of material. This can get really pricy in time and lost work when you loose a otherwise good blade to unpredictable results in ht “CRACK...PING...WARP!!!! Makes known toolsteel bar cheap by comparrison. Good looking pair keep them comming du

-

Just a box of dirt, or a simple side blast forge

DuEulear replied to Charles R. Stevens's topic in JABOD - Just A Box Of Dirt

Off topic i know someone said the same when i put in my kids sandbox years ago as tgere where many strays in my verry urban neiborhood at the time....... 5 years never a cat poo to be found. tore out the sandbox when kids where grown put in an urban chicken coop. I had to kill 8 racoons in the first year to protect my 5 birds. Suddenly there where stray cats all over my yard where i never saw them before lol. I need to build me a forge like that btw Du -

Nice i never would have come up with that thanks again. Du