-

Posts

201 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by DuEulear

-

I know it is a bit overboard but i don’t allways have a striker when i wish i did . I happend upon another 6” leg vise for dirt cheap so i set this one so it is about 1” taller than my anvil. Susan

-

Awesome piece of home hoby macheneing pretty cool what can be done with just files and time ( no fault using the power file ) good work susan

-

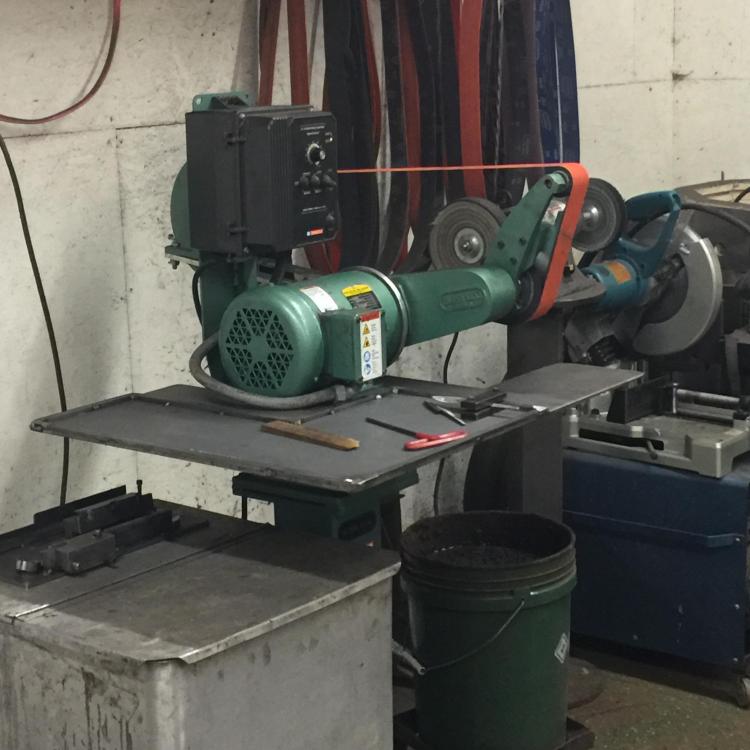

Hey all just felt like showing the shelf i added to my pedistal mounted burr king. Kinda needed a place to set tools and knives while working. Better yet it seemes to be just about the right weight to counterbalance the grinder on the pedistal mount. Which cancels out the occational vibration the grinder has that causes the pedistal to wiggle back and forth.

-

My first knife

DuEulear replied to Potato-Demon's topic in Knife making Class General Class Discussion

Np potato , just remember perfect practice makes perfect stuff lol my terrible work is no better .... Amen to that jhcc one 1/4x1x36 “ bar is at least 4 knives depending on size it might be ten pick an alloy of medium price, maybe 30$ Susan -

Ive got one just like it at a barn sale for 5 i think i use it anywhere i need a dead blow works great. If you ever want rawhide for cheap just buy a rawhide dog chew and soak it so you can un tie it. Then you can unroll it flatten it out and use it for well.... rawhide . Make what you like lol susan

-

My first knife

DuEulear replied to Potato-Demon's topic in Knife making Class General Class Discussion

Thanks for the info on RR steel no i cant give doc on that one that is why i gave it a big i think. I was quoting someone from memory Sue -

My first knife

DuEulear replied to Potato-Demon's topic in Knife making Class General Class Discussion

Ok i am gonna try to give you a few pointers if you want to make a knife from a railroad spike it can be done just fine the hc ones are 1045-1060 i think it will hold an edge but not for long. Heat treating a knife while there is still major cleanup and stock removal to be done is counter productive especially as you are using a file to do most of your stock removal. It will cut aneled steel better than hardend. The main diffrence between a master knife maker with all the toys and a hobbyist with a 50$ shop is the speed with which you can produce a quality product . I forged and cut my first blade with a file just so i would know how . Your first knife looks as if you were rushing at every step. And preforming steps out of sequence and ommiting some entirely. Slow down, do some reading , take your time if your first knife takes 80 hrs to make a beautiful hunting blade that will last a lifetime and you had fun making it the whole time, then you are ahead of the game. If you want to make money at it then buy the toys so you can do the same quick. But slow down for now the fun is in the learning susan -

Just the cutting ability of white steel without the price. It is somewhat hard to come by round here all though there seems to be a guy selling it on ebay lately. and a funny thought experiment du

-

Hey i had a thought the other day snd wondered if anybody has ever tried this ? My crazy idea was to start with 1095 stock and seal it up in a box with charcoal as a carbon donner. Then case harden it to attempt to acheve the carbon content of white paper steel 1.1-1.4% Anyone think this might work? just a crazy thought du

-

Its in the steel rack waiting for me to finish Lol

-

So 8 years ago i started this dagger and i never finished it all that was left was to put the handle on and polish it up. Finally got around to it this weekend. the blade is hand forged L-6, 1018 cross guard and kingswood handle with a copper pommel. The edges are cannel ground and sharp enough to slice paper with effort. Good and durable for a stabbing implement.

-

Lovely

-

Templehound another beautiful piece, i hope this is a compliment on your fine work. I read the title and clicked without looking at who posted this . With just the first picture i said in my head “ thats templehound” congratz another georgeous blade du

-

Tis true they are very easy to make quickly. I am lazy about wood work as my shop is in my attatched garage at the moment so i don’ have a good place for my woodworking kit as sawdust buildup in my metalshop scares me when it comes to fire risk du

-

I am lazy and cheap so i buy my handles from house handle usually a dozen or so at a time they also sell wedges by the pound. Enjoy

-

Ok i will give this one a go. I have a carbide chop saw in my shop at home and i work for a steel processing plant we manufacture decarb free tool steel bar from HR plate. Most of the saws we use to rip cut bars from plate are cold saws. Hr tool steel plate is sold in anealed condition but we have run into hardend spots usually near a flame cut end that are only 1/2 inch thick. But destroy a 24” coldsaw blade almost immediatly. there are diffrent speeds and feeds for evry type of toolsteel. And blade lubes misted when cutting it. What alloys are you making damascus from? Check your blade you may have removed teeth. if you need a new blade dont resume the same cut you will only kill it. flip the billet and try from the other side personally if i allready had trouble i would re anneal then try again or finish that cut with a hot cut on the anvil. Feed slow but steady on toolsteel tont push too hard the blade needs time to work Air cooling a tool steel billet is usually a normalizing not a full anealing. I would suggest bringing to just below critical and a through soak then slow cooling in vermiculite wich will take a billit that size about 12-20 hrs careful it might still be toasty the next morning . Susan

-

I had a blacksmithing buddy more experienced than me get all excited how i managed a brown finish since he had trouble doing it any way other than the slow way. Cleaning weathering then finishing Slag, thankyou but it is miss. She or her lol

-

The baking soda is the way you can also make a base solution by dissolving it in water then just soak the workpiece. If you let that light powdery rust take over for a week or so then proceed with a paste wax finish you will end up with a really nice brown finish think instant antique look

-

When i was in 1st grade i learned metric and it was super easy i never forgot it but i was sad we failed to convert. It is not awkward at all when you specify lumber or distance in metric or even steel. Yes converting is difacult but if we did it in the 80’s it would have been easier. I have allways found it funny when an american says “ no i use miles and pounds i an a American” . Diddent we fight a rather brutal war against king George to have the right to our own country yet here we are the only nation on earth still using the british imperial system. hilarious

-

Will check thanks for the tip frosty i think the motor is good i just need the 3phase to run it. I live in the boonies 2nd house from the end of the grid

-

I diddent really have space but for the price i couldent pass it up

-

I suppose it will come down to what i can afford as i am kinda broke. i realise a rotary will give better power but a vfd is cheaper. It will come down to what i can find in the next month or two untill then she is a xxxx of a nice paperweaight. But it gives me time to paint her and fix the few problems i have. du

-

A machinist buddy of mine spotted a mill at auction and let me know so i could bid on it. I had very little money so i placed a 180$ max bid and walked away with a legun ft-1 knee mill 2hp i think? Quite rusty but serviceable. I only paid 115$ out the door moving the 2600lb beast was a trick but i got her home. Picture shows her partly torn down for cleaning the knee is a bit tight all the travels work spindle and quill are in great shape power feed works and so dose the dro with a bit of cleaning and a vsd to run the 3 phase i might get away with a 400$ mill du

-

Repurposing a soft anvil

DuEulear replied to RogerrogerD's topic in Anvils, Swage Blocks, and Mandrels

You could set it up as a regular anvil and use it for all your hot cut work so you dont hurt your chisels or good anvil -

If money is no problem h13 for hot work chisels punches and hardies s7 for hammers and punches Salvaged material you simply need to make a test tool and see if it is sutible as you really have no clue what you have i hear suckerrod is good for most tooling this is by no meanes a compleate list just a atarting point du