-

Posts

368 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by IanR

-

Thanks for all the comments fellas and Beth, oh, and Bob's wife. Well got a pleasant surprise this morning, the nursery rang me and asked how much I wanted for the teapot because one of their customers wants to buy it! This kinda complicates things I guess, the nursery suggested making another one for the lady, but I was thinking it was like a one of. I have to let him know a price tomorrow so I'll see what I come up with tonight. Cheers Ian

-

Thanks for the comments fellas,the nursery's at Werai http://www.countrywideps.com.au/werai.htm the comp finishes on the 17th Oct. so thats before Moonys. Yeh, I was worried the competition might depend on how many mates you have voting and today I found out one of the entries is from the Girl Guides so they might get the sympathy vote. But as I said I'm just stoked that the idea worked :)

-

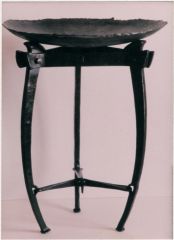

This a teapot sculpture I made for a local nursery/tea-house who called on artists to make a teapot for their inaugural sculpture competition. There was 11 entrys using all sorts of media and they will sit at the nursery for a month while customers vote on them. Although the $500 prize money would be nice I had great pleasure making this because after thinking of the idea I had no formulas or guidelines to make sure the whole thing looked right and would balance. After welding the "pour" to the base I suspended the teapot from the rafters of the workshop and used a light spring clamp to bring the two pieces together.Well, there was much celebration in the workshop after welding it all up and gingerly removing the rope holding the teapot and the whole piece sat there balanced. The arms on the base are 12mm rebar with the ends spread and punched to take pegs, the other materials used are 50mm x10mm flat(pour), 10mm round (teapot), 16mm x 3mm flat(teapot),16mm round(handle) and 25mm round(forged into a ball for the lid handle).Base is sprayed with zinc and black anti-rust and the rest is coated in a protective oil which drys to a hard film and should last 12 months before needing a recoat. Cheers Ian PS I used wood chip to cover the base

-

JA, all the best with your home and workshop, the media reports dont do justice to the amount of damage done.

-

"Does Fosters actually sell somewhere in the world? I know I would'nt buy it for love or money here in Oz" My thoughts exactly Phil, I think Barry Mackenzie was the last bloke to drink Fosters in Australia. :D

-

Thanks for the video Grant,it's great to see old machines put to good use. The heated bars seem to come out of the induction coil with two distinct heated areas, is the coil set up to heat two areas where the upsetting is to occur? Cheers Ian Ross

-

Get " HAMMERED " at MOONY'S

IanR replied to Dale Russell's topic in Events, Hammer ins, Where to meet

I'll be there and ............ sorry just me! :D -

I had no idea we Australians were part of Europe :rolleyes:

-

I take my hat off to volunteer coaches Rob, but you've got to have some time for yourself. Cheers Ian

-

Thanks for sharing Phil, I was flat out today turning some 25mm round bar into a 50mm ball. What size forge do you use to get an even heat on the larger pieces? I guess we dont do a 50 hour week out here we just squeeze it into 38. See you at Mooney's Cheers Ian

-

Hi Matt, I like your gate design, well done! My two bobs worth, I was concerned that the main part of the gate only hangs from two points on the scrolls, it may pay to add a peg style hinge at the bottom corner to bear some of the weight.I assume that the upright off the wave forms a spring loaded catch, this may be better made from an old coil spring straightened out as mild steel may succumb to some over zealous person bending it too far and it not returning. Lastly, I'm not sure how far from the water you are up there, but protecting mild steel from salt spray may mean painting with a good quality paint. You could use stainless but that would induce pain in your wallet and hammering arm . Most of all have fun making it. Cheers Ian PS See you at Get Hammered

-

I was curious about the timing of your visit in relation to "Get Hammered". I think double edge is in Brisbane which is about an 11 hour drive north of Sydney. "Get Hammered" at Braidwood is about 3 hours south.

-

-

Though not a perfect replica of the human form, they look really animated. I like them a lot,I too like the loin cloth, well done. Ian

-

-

Here is a cake slice I made for my Mum's birthday today.

-

-

Dale,mate this is terrible news, after all you both have been through. All I can say is be strong and I hope justice prevails. You will both be in our thoughts. Ian

-

Get " HAMMERED " at MOONY'S

IanR replied to Dale Russell's topic in Events, Hammer ins, Where to meet

Longstrider, Braidwood is about a three hour drive from Sydney, you may want to ask the Good Lady if you can stay Saturday night Cheers Ian -

Nice looking work,great informative photos. It's always good to see photos of tooling and how they are applied, thanks for sharing. Cheers Ian

-

Thanks for the comments guys. Edge I didn't give much thought to the ball cracking I just assumed because the ball was large enough and the claws fairly fine there wouldn't be a problem. The caws were cupped first, then half their length heated before putting the ball in and positioning the claws with a pair of circlip pliers modified to make a small pair of scrolling pliers. Cheers Ian

-

Some of us have trouble getting our sons to take an interest, way to go Dennis and congratulations to your daughter on her graduation.

-

"Do you know a Blacksmith in Mittagong by the name of Joseph Balog? I was in Mittagong about a month ago with the family and convinced the wife to go to a vineyard that just happened to have a Blacksmith on site." I knew several years ago there was a blacksmith at that winery, but never got around to going out there. I thought he may not be there now, I must must go and check him out. Cheers Ian

-

Got around to finishing these today, just need to make holes in the hinge brackets and mount them. Cheers Ian