ytuyuty

Members-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by ytuyuty

-

You didn't answer any of my questions.

-

If I knew enough to ask intelligent questions about this matter, then I wouldn't have asked for help. I am diving into a new realm, have read a lot on the matter, but still cannot understand what I am doing or what I am doing wrong. Is that too difficult for you to understand? Is this a forum for sharing information? Or merely forum where experienced people can stroke their egos by talking down to people who don't know as much as they do? Serious questions, all 3 of them. That Frosty guy has one serious bad attitude, and its not the first time I have seen that behavior from him on this forum.

-

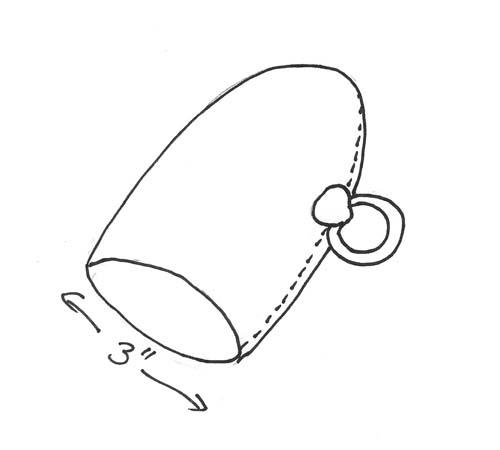

Thanks for the info. What I made before was a non-weight bearing butt joint, just a cap, shown in the photo. But now I need to make another one with a 1" brass ring on the seam that will need to hold 5 pounds nominally, and 10 pounds with bounce stress. It's got to be cosmetically pretty. Do you think solder would be strong enough? Or do I really need to learn to braze this? Thanks Marc

-

My, my, someone asks for help and you're one helpful pal. Have a nice day. BTW once I did successfully braze or solder 20 gauge sheet brass, butt to butt, using this technique, but I got lucky, don't know how I did it, and can't do it again. And 2 years later the connection is still doing fine. So your claim that 20 gauge brass can't be butt soldered is false, obviously you don't know what you're talking about, and I can't help you.

-

Ok So I am trying to securely connect brand-new shined and cleaned 20 gauge brass sheet. Butt joints, shined and clamped. So I need to get a oxy torch instead of a MAP torch, and dedicated brazing rods and nstead of silver solder. Is that correct? I tried heating slowly, but the solder doesn't melt when I touch it to the brass. I really have to heat the brass pretty hot (red) to get the solder to melt on contact. I have also tried adding heat slowly, waving the flame in and out but the solder just beads up and rolls all over the place except into the joint. No matter if I go cool or hot, the solder beads up and rolls everywhere except where I want it to go. Ive even tried a pencil torch to use a lower heat and a more focused flame. Same results.

-

Okay, I'll admit it. I can't braze anything. And I don't know what I'm doing wrong. In the videos, it looks so easy. Clean, flux, heat, and the joint just sucks up the solder. Done! I'm trying to braze C260 cartridge brass to itself with silver solder. I clean the two surface really well and apply brazing flux. Then I heat with a MAP gas torch until the brass just starts to turn red. When I apply the silver solder to the joint, the silver beads up and rolls everywhere EXCEPT into the joint. I've tried brazing a cooler and hotter temps and get the same results every time. Can someone help me? I really need to learn to braze brass butt joints (20 gauge brass).

-

Splitting a bar of steel to insert a steel cutting edge

-

Thanks for the advice. I don't chisel very often, but I'm losing so much heat getting my work clamped and then climbing up on a box that I might get another vise and mount it low. So do you get a second post vise and chop off the post to get it mounted low? Most of my vise work is grinding and filing, and it's at the perfect height for that.

-

Trying to chisel something mounted in post vise is killing me, it's too high. How are you clamping your pieces for heavy chisel work? Do you have a vise mounted low, or do you just stand on a box?

-

^^^ JlBlohm your posts are fine

-

information on socketed axes.

ytuyuty replied to basher's topic in Axes, Hatchets, Hawks, Choppers, etc

I like.... -

Steve, I went back and re-read my books on steel and smithing -- then I realized that you are the author of my favorite book! It's in a private collection now. I spoke at length with the owner. I've made reproductions of a few of his knives: site

-

Thanks all I can read all day about A2 but the reality is that nothing that I've read about A2 specifically addressed my questions. I've been using mostly junkyard steel for my projects (I like coil springs), and have made woodworking chisels, gouges, irons for hand planes, hot cutoffs, steel chisels, hold fasts, knives. But I've started buying known steels recently. Here is one of my 16-inch junkyard coil spring knives with an octagonal briar burl grip, a reproduction of an actual medieval knife in a museum collection. I bought some 4140 to make hammer heads, guess I'll use it for other things, too.

-

Pretending I'm a blacksmith. It's just a hobby, trying all kinds steels and projects. I like to make my own woodworking tools. I'm trying to understand the reasoning behind using this or that steel for this or that purpose.

-

Okay, help me understand I was thinking since the A2 can be air hardened, it doesn't matter how hot it gets while drifting, I can just quench it and keep drifting, and then let it air cool when I'm done. No?

-

Made my first 2-1/2 lb. rounding hammer with borrowed tools, now I am looking to make some chisels and drifts for myself. The steel I have lying around my shop include 4140, O1, W1, A36, A2, rebar, and some truck coil springs, leaf springs, and axles. I can also get jack hammer bits. I'm thinking the A2 is a good steel for making a hammer eye drift. Am I correct?

-

Hardie tool stem - loose in the hardie hole

ytuyuty replied to ytuyuty's topic in Anvils, Swage Blocks, and Mandrels

That makes sense Charles I welded some extra steel onto my stem to get it snug -

I tried with a Propane torch but that was a joke. I see that I'm gonna have to upgrade my shop a bit.

-

It's high-carbon steel - auto coil spring I can still water quench and anneal after upsetting?

-

I could use some advice with upsetting the middle of a 3/4-inch bar. First problem is that I have a propane forge for knife-making (interior 4" x 4" x 20") so I cannot spot heat the middle of the bar. I end up heating 8" to 10" of the bar, so when I try to upset the bar it just bends no matter what I try. I have tried holding the bar at the 4" x 4" opening to spot heat, but the bar just doesn't get hot enough.

-

My latest knife, a reproduction of a manly 15th century medieval ballock dagger. Prudish Victorians called it the "kidney" dagger. Forged from O1 tool steel. Ebony handle. Veg-tan leather sheath. Overall length 16 inches. This was a weapon of war that was designed to combat the ever-increasing use of plate armor that was being worn over maille. Long, robust daggers with reinforced points were needed to stab into gaps in the plate armor, and breach the rings of maille.

-

Ok Slag, you win

-

I dumped 4 (FOUR) drowned mice from my slack tube today. Water must have a smell to animals, and the mice must be looking for water. I am going to put a cover on my slack tub and add a second tub just for catching mice!

-

Removing Grinding marks

ytuyuty replied to ThorsHammer82's topic in Blacksmithing, General Discussion

Sorry. You can make the weld disappear and smooth it all out with the angle grinder. That's how I deal with welds.