gote

-

Posts

779 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by gote

-

-

Nearly the same here We need a certified safe securely bolted to the wall. However we can keep bolts and ammo in the same safe. I keep my guns in the neghbours safe. They are expensive. The safes I mean.

-

First tongs

in Tongs

If you know the density of the plasticine you can weigh it to get the volume then multiply by density of steel. To get the density of plasticine, use water displacement or make a good cube and weigh that. Steel density you can google.

For tongs I would not bother. I start with stock that is long enough to hold comfortably with the hand. When drawing out the reins I stop and cut off and that is it.

-

I concur with Thomas, My oldest hammers (150+ years) have no ears and the Mästermyr tools do not have any. In my part of the world I have never seen a hammer with ears. (only on axes but never with holes for nailing) Carpenter's claw hammers used to be secured by two (loose) strips of steel. These had a kind ot hook that pulled the far corners of the hammer head towards the handle and were nailed to the handle. The hole in the head had its smaller end on the far side.

-

I agree 100% with John and Timothy. In my corner of the world, files always come with a plastic handle and there is a hole in it. I am quite happy with the shape but this is my personal preference. If you look at the bottom of the "Show me your shop thread" page 4 near the bottom you will see my most used files hanging on nails on the wall close to the vise I use when doing serious filing. I avoid having anything plastic near the fire so the material is no problem. Old files without handles, that I find among junk, usually are so worn that they are useless as files. I cut and grind them into bits to use in the lathe. If they are useable I make a wooden handle (with a hole in).

In my experience it is good practice to use the full length of a file or saw. Not only is it less wasteful with the tool, It also seems to cut better and definitely cut truer since there is more control. The further out one holds It is easier to keep the tool straight when moving it. I find the traditional way of holding a file as shown in old books (and taught by my master) to be the most efficient.

-

On 2017-03-07 at 5:42 PM, ThomasPowers said:

Yes, works better with a cave fire. We've also discussed using fire brick on top of the coke to make a jet of hot gasses and hold the ring in it till temp and squish weld it. an earlier Variation on the modern torch. IIRC one fellow had even said he had done a few using a blowpipe as jewelry used to be hard soldered with.

Thank you. Sounds as a good idea. If I ever try to make a small fire welded ring I will try it.

-

The iplosion of a steel vessel is not like the implosion of a TV-tube. I have seen a vessel (several cubic meters) that was full of steam when Mr Murphy let in cold water. It looked like what you can do to a beer can with your hands but there was no damage to anything or anybody else. We always had our autoclaves designed to withstand a mishap like that. They were in principle, long tubes 7-8' diameter and 3/4-1" wall thickness. It was enough to put rings on the outside to make sure they did not implode or (rather squeeze flat). I should think that those pressure cookers, I have seen, would not be subject to any damage since the cylinder part is so short. The damage type is buckling and the "gables" stabilize the cylinder and prevent that. However I would not use a pressure cooker.

In my part of the world a standard steel tube of appropriate diametre plus two gables of steel plate with gaskets of rubber sheet would fit the purpose. No welding needed or recommended. It is possible to find tube specified to withstand 100% vacuum. I would attach a nipple to the tube. (drill and thread), Lay one steel sheet on a table, A sheet of rubber on top, put the tube on the sheet then next sheet and the second plate on the tube. The vacuum will keep the bits annd pieces together. Obviously the tube should be cut cleanly in a lathe or other machine. I am not talking about cast Iron sewer pipe but pipe for pressurized applications. A supplier of steel tubes to the industry would be able to supply the tube cut to appropriate length. If you need a window , cut a hole in the upper sheet and put a sturdy piece of Plexiglass with another piece of rubber on top.

-

Thank you Marcy, I am really impressed and I look forward to the video

-

9 hours ago, jlpservicesinc said:

funny how a good majority of blacksmiths turned to Auto repair..

They used to repair horse drawn buggies and then they repaired horeseless buggies

-

14 hours ago, ThomasPowers said:

It's sad to talk with people who don't realize that things have changed from use of bloomery made wrought iron to the indirect method to cast steel and Bessemer/open hearth process steel to BOF, etc. and they are still trying to apply methods that were associated with the properties of a specific material.

To apply old methods because one wants to try and learn or to reproduce a certain effect, I see as a good thing. Ardent believers that one MUST do things the way they did in 1867 exactly, (choose your year

) I see as weak needing a harness of kind to support themselves.

16 hours ago, jlpservicesinc said:

) I see as weak needing a harness of kind to support themselves.

16 hours ago, jlpservicesinc said:I have to confess that sometimes when I read what I post I wanna punch myself in the face...

Not in this thread I am sure.

-

I finally got it.

It is a glass jar with stuff in not an empty jar of shiny rock.

It is a glass jar with stuff in not an empty jar of shiny rock.

-

Thomas, Do you mean sticking the tongs into the fire and press before taking the ring out?

-

I share Frost's fear but screwed into a baseplate I agree you will be all right. It sure looks fancy.

-

Very cool design. I love it as a piece of carpentry but have you used it a lot? It seems to defy the usual thoughts about stands being very rigid. Poplar is not the hardest of woods.

-

Sand has the disadvantage that some kinds make a lot of (abrasive) dust. Some will also slowly shift by your stepping on them. My long term goal is to put in a wooden floor over my sand. (No solid wood does not catch fire easily)

-

The jar loks like porphyr (English spelling??) in which case it is quite valuable. A hard kind of rock that was popular for expensve pieces 200 years ago. I may be totally misled by he pic but check it and do not sell it cheaply.

-

I put one in my forge exhaust pipe to make sure the temperature did not go so high that the zink started burning. I removed it when I found that the temperatures were so far below that monitoring was meaningless. Besides we now have cheap IR-thermometers. I might put it in an old kitchen oven without thermostate that I someday will turn into annealing.

-

On 2017-03-05 at 2:30 AM, Frosty said:

Good thing you found a shovel then.

It's quite a score and there's more at the dump site. SWEET.

It's quite a score and there's more at the dump site. SWEET.

I wouldn't wish to be born last century were I a woman. The chances you'd be doing "man's" work would be slim and make you an outcast in the process. It wasn't till WWII and the Rosie the Riveter generation women finally broke into the manufacturing market.

Frosty The Lucky.

What is the last century Frosty? I think you, I and our wifes were born in that.

Seriously: Women in the old days were no wimps. They had to do the mens' work when the men were out fighting wars. They also managed businesses as widows - sometimes quite sucessful. Vide Veuve Clicot. "the yellow widow champagne". The feeble swooning woman is a late 19th century middle class phenomenon. My great grandmother and the generations before her did not even change their names when married. The largest runic inscription ever (The one with Sigurd and the blacksmith) was comissioned by a woman comemmorating that she had built a bridge over a river.

-

16 hours ago, JHCC said:

Over on the right-hand side, are those springs to hold bar stock? Or bar stock to hold springs?

The springs are "stock" that hold "tools"

i.e. pieces of pipe I use as levers when bending or tightening. They just happened to be there when I took the picture.

i.e. pieces of pipe I use as levers when bending or tightening. They just happened to be there when I took the picture.

-

-

Beech, You should not be sorry. You just gave some of us the opportunity to show off our erudition.

I have a nice old apparatus that determines mass with an accuracy of 0.01 milligrams (If I do not sneeze) and I have another that determines weight and is calibrated in kg which theoretically is wrong. The first is based on balance and the second on springs. If we assume that the second one is correctly calibrated it also determines mass by determining the weight and translating it to mass. Now we normally refer the use of any of these as weighing so it is natural to talk about weight. Weight should theoretically be expressed in Newtons since it is a force but this particular force, which is the force excerted by the combination of mass and gravity, is by common consent expressed in kg. To confuse the issue there used to be a Kilopond (Not Kilopound) which was (If I remember correctly) the weight of one kg at 9.81 m/s2 gravitational acceleration.

I have never heard it called a metric pound but in Germany you buy groceries by the "Pfund" which is 0.5 kg (not 0.45) and is used for practical reasons as said above.

A mile is really one thousand (mille) double steps by a Roman soldier on march. (Which tells us something aout the stature of Roman soldiers). This mile which is approximately 1.6 km was used in some European countries but not all. Some, including Sweden, used longer miles (all different of course) just over 10 km. So today Swedish people mix "kilometer" and "mil" (today meaning 10000m) in their speech. I have 20 mil to Stockholm but 26 kilometer to Örebro and my car uses 0.9 liter per mil.

I assume most of you know that a 1/2" pipe has no dimension that is 0.5" In an attempt to become metric it has been renamed NW15 but it is of course not 15mm anywhere either.

We have a similar problem with timber. It appears as sawn and as planed and ouf course the planed dimension is different from the sawn dimension. but we are using the same names.

Welcome to Chaos Manor!

-

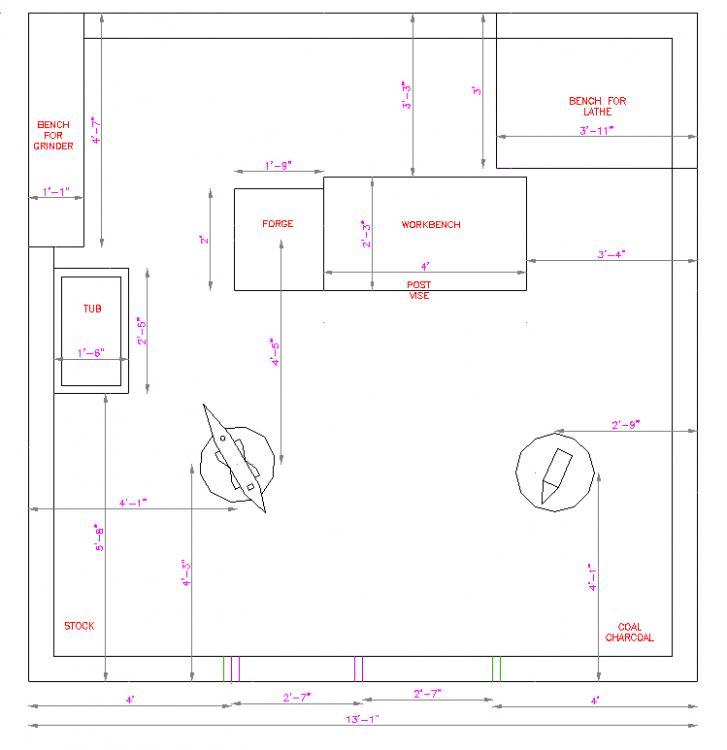

I was perhaps not quite clear, I first tested out the floor plan then I built a shell around. The drawing is just documentation of the result. By the way, I usually put a rim of clay brick around the sides and back of the forge to allow a deeper fire. A coupleof them can be seen below the forge. Dong it that way it is easy to remove one to get a "window" for a longer piece. I think the flowers are a cute touch - especially when they sit in a rather expensive champagne bottle trying to make believe that this is the normal drink on the premises.

-

Frosty,

I appreciate your good intentions in giving friendly advice but this floorplan is the result of my trying out various positions and ending up with a layout that suits me but perhaps not you. A shop layout is never final. The day there is not need to change, it has turned into a museum. The same for a home by the way.

Said that, I have used this for soon two years and I have not felt any need to change the central triangle of forge anvil vise. The lathe came in later and forced some moves and I have moved the tub up but that is all. I always work as much as possible with long stock that I can hold in my hand and prefer to have the bench close to the forge since that allows me to use the bench as support for the stock that is in the fire. To me it is an absolute requirement to have the bench adjacent to the forge. There is sufficient space to work the lathe. The only awkwardness is that I have to walk around the benchplusforge to get to the gears but I seldom cut threads so I can live with that.

A previous owner messed it up but the post vise is designed to be able to rotate around a vertical axis and one day I will make it do that. For the case you envisage of bending a large piece, I would today bend it in the horizontal plane instead. Re distance to tools, I put the tools I intend to use on the bench so they are close eough. The hotcut lies on a shelf in he wall close to the anvil. Since my stock rests on (a support on) the bench I am free during the heat to move any gadget as required. I always start with an empty bench so anything I need can be put within reach. I am gradually cluttering the walls up but I do not have that assortment of tongs and hammers so many seem to acquire.

I post two more pics:

#1 from the door towards the left corner showing anvil forge, tub, grinder vise etc (I am looking for a better grinder) Note the piece of wood on the bench that gives support in 1" increments to the cold end of the stock

#2 from the anvil towards the lathe showing that and the second vise.

You may note that this is not a pole barn design but a cross brace one. This is the normal way to build a country place shed/outhouse here. The colour is very traditional. Cottages for pople have white corners. workshops etc have black.

-

I was doing a couple of hours weekly in a blacksith shop not far from here but the master became ill and the weekly dried up. I decided that "Now or never" and started looking for equipment. I became lucky and found a farmer who was selling off his surplus junk. I bought his best anvil, a field forge (for cavalry farriers in the field) a bick and - a rare find here - a postvise.

I started in the yard behind the house and the first job were some foundation irons for a gazebo. Next job required the vise to be set up so I made a heavy workbench 4" square legs and 2" top.

The shop was a tarpauline. Next step was to clear some surface in front of the old carpentry shop and to position the bits and pieces there. I moved them around until I got a layout that I liked. The shop was still the tarp but It started to get organized.

Next year saw the erection of a framework around my workplace and a roof of steel sheet that I got for free. My 'shop to be' survived the winter with walls of plastic sheeting. Next year I put up the walls built doors etc.

I post here the layout and a picture from the outside. Under the green sheet is the snow blower that I have only used twice this winter. The sacs contain coal and the two barrels are for carpenting scrap. One for untreatred wood that goes to the bonfire, one for treated that goes to destruction.

I will post pics from the inside a little later.

-

I am afraid that it is a mistake to believe that ventilation is always beneficial. If your shop is cold and maybe thermally heavy (concrete walls or basement location or...) the more air you get in from the outside the more water you bring in. If the dew point of the air outside is higher than the temperature on something in your shop, outside air will precipitate condensation on that something. On the other hand, if the dew point outside is lower than the temperatures in your shop, the outside air will have a drying effect. Google 'dewpoint' I have not time to explain more in detail.

Carving Letters in Steel.

in Metal Sculpture & Carvings

Posted

Thank you very much for the info. Inspiring example