-

Posts

1,746 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Anachronist58

-

What did you do in the shop today?

Anachronist58 replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey Hoosier, I suggest you go into your post and remove the @ symbols from your post. They confuse the Forum software and may get the Moderators on your case. Use the three dots in the upper right corner of your post to bring up the edit feature... Mrs. Taylor is a HOOSER, a little different! I am wondering if the two terms are related? Robert Taylor -

Emerson 1" x 42" Belt Sander / Grinder

Anachronist58 replied to Anachronist58's topic in Grinders, Sanders, etc

Thanks for the information, Farmall. I will check it out... Robert Taylor -

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

Yes it took me four pieces to work out the basic die sequence, but I am quite happy with the results. Took bad I did not document it. All by the numbers now, that I did not write down: Now to build the next size! -

Emerson 1" x 42" Belt Sander / Grinder

Anachronist58 replied to Anachronist58's topic in Grinders, Sanders, etc

Fantastic. Robert and Sheila's best wishes from the extreme southwestest of the United States! Every time I want to grind something, I start for the Emerson. But I BROKE it. Yes, it happened just like that. I worked with big machines. You brought the work to the machine. I found that to be quite nice. The Emerson is the smallest big machine I have, and once you finally set up, and with proper abrasives, you will kick yourself, and, to restart the running pun, you will realize why it is my bread and butter.... Robert Taylor -

Reminds me of my baby brother. Was a carpenter building window displays for Nordstroms. Someone heard a rumor that he knew computers, He was asked, "can you troubleshoot my cash register?" "Sure", he lied. His previous experience was hacking and vandalizing network equipment. He went on to become a bonified IT executive in the corporation. I think your client could be a top gear operator. Let the pudding prove itself by long lasting consistently fine flavor. You have good taste, methinks...

-

What did you do in the shop today?

Anachronist58 replied to Mark Ling's topic in Blacksmithing, General Discussion

Hey Hoo (Hoosier), my wife is an Ohio Hooser. I think you are a natural. Good luck, have fun! Robert Taylor -

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

Frosty, I love this! Do you split your drill points? Most of the jobs I serviced required split points, and I would hand split production drills and machine split coolant fed drills. On the Flypress, 'angle iron' can be your friend. I have 'bed iron' that is over 70 years old, and some much newer. This has been mentioned by numerous IFI members, that bed iron is nothing to sneeze at. Personally, I love it for tooling, one can even cold shear milder steel across bed iron... Now as for press work. If one does the kind work that I do, angle iron is indispensable. As shown in the images below, having as many sizes as possible in my press kit, affords me a lot of flexibility in progressive forming. This is where I am really missing my belt grinder for dressing the outside radii for nesting angles within angles... Robert Taylor I think my brother could use 20, 30, of these... -

Emerson 1" x 42" Belt Sander / Grinder

Anachronist58 replied to Anachronist58's topic in Grinders, Sanders, etc

I must say, I am really missing my belt grinder. That first driven pulley on the belt circuit, had a very damaged ⅝"ø shaft with two bearings on it. I bought a new length of ⅝"ø keyed shaft, and started to press out the old shaft on the three ton rack and pinion press. No luck. The bearing and shaft assy were branded Hoover. So, over to the 5 ton flypress. No luck. Over to the 12 ton hydraulic press. KA BLAM!! Turns out that the inner race was integral to the shaft. Bought new bearings, and need to turn some new housings. Have put it off for far too long. Will mention this on my press thread, but I must say for most folks and most applications, a good belt grinder is a fine stand in for a bench grinder. I have a 500# 'bench' (tool & cutter machine) grinder, so it is quite an endorsement, coming from me, in my most humble brag opinion, of belt grinders, per se... DAS Woof, that sure looks a lot like my Emerson - sell it for parts? Pictures soon, we hope.. Robert Taylor -

OK, you went from roasting your foot in front of a radar feed horn, to being pinned under a gator? Glad you made it. I concur with George, smithing may do the trick. Thank you for your Service. Robert Taylor U.S. Army Cold War.

-

Daniel Moss Candlestick Challenge video

Anachronist58 replied to jlpservicesinc's topic in Blacksmithing, General Discussion

Wow. That is a HUMUNGOUS amount of build up on the track drive sprockets and idler wheels. Speechless... Robert Taylor -

The Sun circles the Earth in a chariot pulled by dragons. Robert Taylor

-

Daniel Moss Candlestick Challenge video

Anachronist58 replied to jlpservicesinc's topic in Blacksmithing, General Discussion

What a treat! Watch your toes! Robert Taylor -

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

I would like to hear more about this tarp, offline, Scott, but unless the wind carries this one off to OZ, I am probably OK for the moment. I believe that you have a credit already on the turbine scrap. Frosty, this grnding wheel is such a great performer, I thought I ought to show you what is under the hood: Originally a 7"ø wheel, now measures 5⅞". Most of that was already gone when I purchased the machine. Just a great wheel... Robert -

Thanks Thomas, this put me down the rabbit hole for four plus hours, and 20 plus newly opened tabs... Robert Taylor

-

Daniel Moss Candlestick Challenge video

Anachronist58 replied to jlpservicesinc's topic in Blacksmithing, General Discussion

Good words from the Crew. I am in constant apprehension of being once again code enforced on my sovereign territory... Jennifer, what IS this tracked vehicle that you are working on!? Robert Taylor -

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

Yeah, Frosty, before I blew up my belt grinder, I had special belts just for grinding these stacks. The bench grinder is slower, but it gets the job done. It is a good hard wheel, and it will get a little dress, for sure. I am not one of those cats who get a big groove in the center of my wheels. My motto is 'let the work dress the wheel'. Robert -

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

Thanks, Jennifer, and yes, now that I know that the process does not result in scrap, I will stack the next three and remove the teeth, round the edges, then forge. The spring clips will also be ⅜" shorter than the ABS. -

Quite the tale, may mister tats give you a wide berth... And congratulations for your success with your offspring. Robert Taylor

-

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

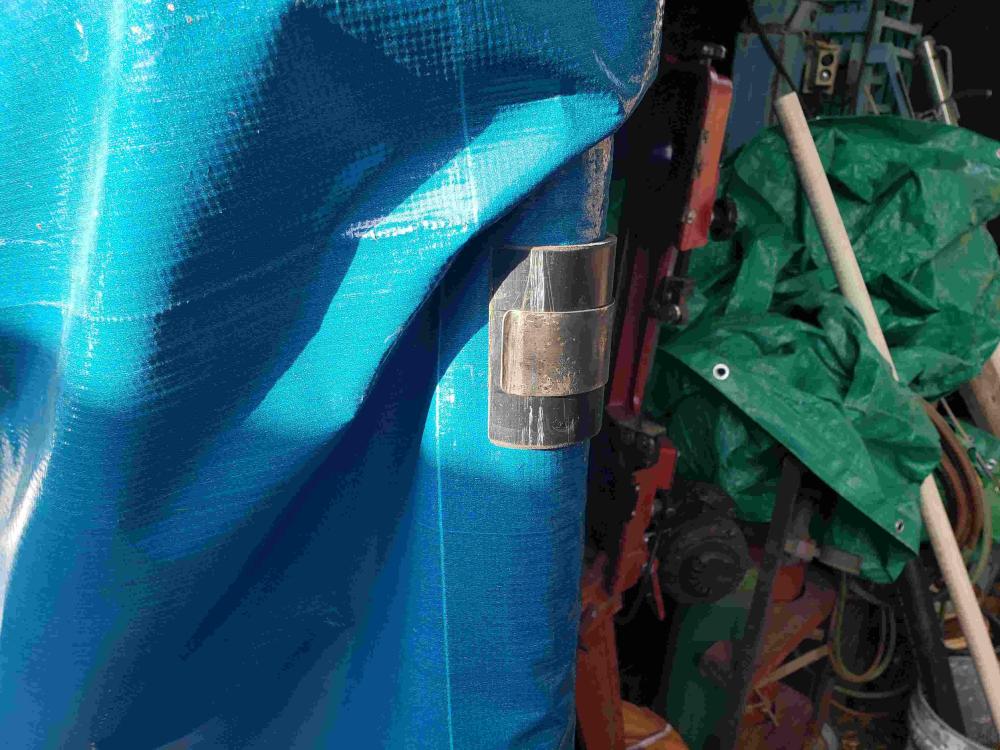

Thanks, Friends. Next project is to cover a 10' x 13' steel frame with a giant tarp, formerly a 14' x 48' billboard advertisement: Now a way to secure the tarp: So, the ABS tube happens to be the perfect size to snap over the tarp and secure it to the steel uprights. HOWEVER, the wind up here on a nice day exceeds the capacity of the ABS alone. The solution is a spring clamp, as shown. This is the same bandsaw material that I have previously described. There was no way that I was going to cold-form this stuff, so time to light the forge. My plan was to forge clip radii on the ends, anneal, form in the press, harden, and re-temper. Forged and 'annealed' one test piece, pulled it out, and although it was now cold-workable, it was still VERY rigid and springy. No need to further heat treat. I LOVE this stuff! Do not forget, it is not difficult to get your work offset from under the ram: Note how the die is shimmed at the rear. I managed to crush the ⅛" wall tube (die) to get the spring clip to deform. Bed frame angle and 'angle iron' are definitely my friends on the flypress! Robert Taylor -

Daniel Moss Candlestick Challenge video

Anachronist58 replied to jlpservicesinc's topic in Blacksmithing, General Discussion

Billy, a mistake like that should have been nearly impossible to make... Robert Taylor -

#5 Fly Press, Via Camp Verde, Arizona, USA

Anachronist58 replied to Anachronist58's topic in Presses

Love my flypress as a vise: Shop heater shell finally gave out, time for a new one: Since the top and bottom are good steel, the press gets to help making cymbals: Needs tuning... Robert Taylor -

I came in from the Wilderness, a creature void of form... I will go for a couple of 8'ø x whatever long (lying horizontal) under my driveway. Point Loma is home to the nuclear sub base.

-

Yeah, it is 8 pages of "almost" the whole gang chiming in on a thread started by a very popular member, so fine, move it to "Everything Else". Just to get on TW's coattails, happens all the time on IFI. Robert Taylor