-

Posts

1,056 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Gergely

-

-

I'm always amazed by your inimitable style. Gorgeous piece!

Bests:

Gergely

-

Happy to see you posting your great work again! All the bests!

Gergely

-

Hello Nicholas and welcome!

Please try and do as PVF Al said. You're not gonna sorry if you do so. Those prices you wrote are very high even in the States.

And as a beginner you don't really need a "real" anvil - so Flatliner's suggestion about reading through the improvised anvil thread is also very wise.

Save your money for more important purchases at the beginning, then make some money with your continously advancing skills, and then you'll find the anvil of your dreams.

Bests:

Gergely

-

Hi GB,

I always start with 3/8"-ish coil spring stock. I draw it down and then I screw it up every single time... Seriously!

Bests:

Gergely

-

On of my favorite pictures here in IFI: Phil's comment on the "Show me your hooks" thread.

-

I just read the sad news that Phil has passed away. Once again a very tragic loss for the forging community.

Rest in peace Forgemaster!

-

If you don't mind a piece of advice: take a store bought one with you when heading to the shop for forging your first. It's very annoying when you find out at the end that 1. the coil was drawn out too thick 2. it twists the opposite way as it should do.

Bests:

Gergely

-

Well, John, you just gave me some search and buy job to do...

That's an awesome looking book, a bit more expensive than 3,49 but whatever.

That's an awesome looking book, a bit more expensive than 3,49 but whatever.

Thank you for posting pictures!

Bests:

Gergely

-

-

Hi All,

Finally the acorn-ish table has followed me home from the cutter shop! It weighs over half ton, 4' long, 2,5' wide, 2 1/4" thick plate on 6 3/8" (160mm) H-beam legs.

I have found out some ways to use it even more than originally planned: I will attach the post vise (2nd pict, on the left in the background) to one of the legs - the vise gets more stability, and I get more shop space. Also a machinist vise and a smaller shear will get mobile platforms. That way it will be possible to just drop one of them in the holes and use it. After use just lift it out and put it somewhere else.

Unfortunately the sensor of my welding helmet died on me so no welds today... Luckily I have other things to do, too

Bests:

Gergely

-

Thank you for sharing! This guy's work helped me to create some new ideas I was struggling with for a while. Now nothing else left but work them into finished products.

Bests:

Gergely

-

That's a cool idea! These better ones go to the use-it-later pile, I always use the ones in bad shape.

A couple once wanted a hanging kitchen pot rack made of an old harrow. I sent them the price and never heard of them since then.

Bests

Gergely

-

Zeroclick: Awesome vises! I really love those elegant shaped ones.

John: I wish you better luck with the snips than last time.

On my part I finally managed to get into the yard where I bought the plate material for the smallish acorn table. Scored 350 kg of 160mm H beams - enough for the legs of the acorn table and also for the legs of the fly press table. No pictures because I got the stuff straight to the plasma cutter shop where they saw them to size.

But Tuesday I made a deal with a guy for the harrows he wanted to sell in the scrapyard. I bought all the 4 harrows he got because that stuff looked really good and old. Disassembled one of the four, and it's pure wrought iron, very nice, not too fine, not too coarse grain - the best for me!

I can make 300 pcs rune key fobs and 30 bottle openers out of that one harrow.

I can make 300 pcs rune key fobs and 30 bottle openers out of that one harrow.

Here are the four harrows:

Funnily there are two of them with almost completely ready openers in them:

Now I must find out how to use the old square nuts these have. I used to make medals of them but they weren't very popular.

Bests:

Gergely

-

Perfect! Can't say no more...

Bests:

Gergely

-

Thanks, Frosty! I try and find the first heart I made a year ago. The difference is relevant (at least

)

)

Hi, Ben! Very nice looking hammers and photos!

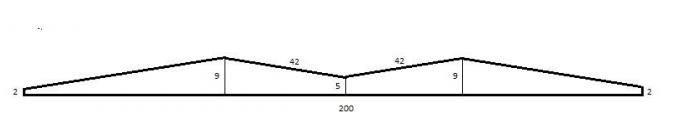

The main change I made recently to enhance consistency is that I switched to laser cut starting stock. Originally it was 120x5x10 mm flat. You can see the new blank in the picture (It's cut from 4mm thick sheet):

Other than that I use only a 30mm dia round piece in the hardy hole. It helps shaping the upper archs of the hearts.

Bests:

Gergely

PS: 40 more horseshoes today

+ blackened the hearts

+ blackened the hearts

-

-

Thank you, John! Looks like I'm turning my head towards the electrolysis basics.

Got 40 hearts forged from 6am to noon. 40 horseshoes still ahead in the evening, if I'm done with those can call it a day

Bests:

Gergely

-

Thank you Jennifer, John and Biggun!

I try and learn more on the subject. This far somehow citric acid hasn't worked for me, maybe I did something wrong.

Oh and I cranked out 50 lucky horseshoes in spite of being away from the shop almost all day... Long days of summer have their bright side(s).

Bests:

Gergely

-

On 8/3/2018 at 5:13 PM, ThomasPowers said:

Gergely; will you do some in stainless for bathrooms?

That sounds like a plan,. Thomas. I really want to get oriented towards bathroom ironings and the only way to do so is using stainless. It's in the very early stages yet, and I'm still working on the how to aquire good passivation effect on 304 kind of steels after forging.

Bests:

Gergely

-

-

-

Baja: Looked after that thread. I'm glad that all worked out well!

And I can happily tell you that I'm an owner of a 970 lbs / 440 kg piece of plate. It measures 1200x780 mm (4' x 2,5') and has 56 mm / 2 1/4" thickness.

No pictures yet because we took it right to the plasma cutter shop where half of it gets 2x2" holes cut in.

So, yippee!

-

Thanks Guys! :)

Wow, Frosty, a 1200 lbs piece in Ak? That sounds like a not every day chance...

Baja: how to forge cutting fluid? wanna talk about it a bit more?

-

Dear All,

I have suffered from serious iron-deficiency lately. So please root for me that I could succeed in aquiring a 800 lbs piece of plate to create an equilibrium in my mind. Coming soon...

Bests:

Gergely

XXL coil springs, usefull ?

in Tools, general discussion

Posted

Hi Bart,

In Europe you most often can run into these spring steel alloys: 51CrV4, 56Si7 and sometimes: 61SiCr7, 52CrMoV4.

All of them are oil quenching steels.

They forge well you just have to take care about not to overheat them. Also no hot forming under 800 C grade. (They tolerate some level of abuse, but it's better to avoid that.)

I have two coils of 32mm dia springs. I use them for power hammer tools - welded on handle, stress relieved after welding. In August I forged a spear head out of a piece - it took the longer forging process good, hardened nicely, no problems occured.

The funny part was to straighten the stock. I used a crane hook in a vise and a piece of pipe.

If they are free, I'd took at least 5-6. They don't use much space, and can be valuable for others, too.

Bests:

Gergely