-

Posts

298 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by norrin_radd

-

My take on the Split Cross/Fredricks Cross

norrin_radd replied to norrin_radd's topic in Blacksmithing, General Discussion

Thanks, I really do appreciate you comment, and your opinion. That's funny because this has actually been on my mind this morning. When I was shown how to make these it was basically just beginner project, which I am still to this day, a beginner. And I would not insult anyone here by calling myself a blacksmith. I'm just here to have a good time. Also I did not know the story behind the original product that you mentioned in your post. Which I think is a cool story and the fact that You can just pop in there for lunch was not lost on me. I always thought it had something to with a "Saint Friedrich", go figure. But your post has really got me wanting to try to make some like the original, sweeping niceties and all so I thank you for that. Not that I'll ever be able to produce such works of art, but it will be fun to try one day. As for just wanting to sell them, that has very little to do with it. I made a bunch of these with my family as a way to work/learn together, there was more to it than just the Crosses. We did put some up for sale (underpriced), just so my adolescent kids might earn a little money. We gave almost all of them away. Where I come from there's a saying, "I'm just going to have tell how the cow ate the cabbage" (fancy way of saying " to be honest with you") no malice intended either, seriously. The Cross I made in the video appeals to Me, for what it means to Me, it's not supposed to be pretty. There's only a few marks on it that really matter. In the immortal words of Forrest Gump: "That's all I have to say, about that." Again, I mean no offense, I do appreciate the discussion. -

My take on the Split Cross/Fredricks Cross

norrin_radd replied to norrin_radd's topic in Blacksmithing, General Discussion

I've heard of that with a circular saw blade, never done it, but I dint know about it with a band saw. Be interesting to see. -

The Original Christoph Friedrich's Split Cross

norrin_radd replied to Alan Evans's topic in Blacksmithing, General Discussion

That's the real deal right there. Nice pic. -

My take on the Split Cross/Fredricks Cross

norrin_radd replied to norrin_radd's topic in Blacksmithing, General Discussion

Glad you liked it and you're welcome. They are a lot of fun to make hopefully you can give it a shot sometime. Thanks a lot, I appreciate that. Thanks for all the great feedback. -

My take on the Split Cross/Fredricks Cross

norrin_radd replied to norrin_radd's topic in Blacksmithing, General Discussion

Thats a good idea. Yeah my band saw is the converted cheapo portaband but it has variable speed. No problem, glad to give back a little. I've learned alot around here, still learning. -

My take on the Split Cross/Fredricks Cross

norrin_radd replied to norrin_radd's topic in Blacksmithing, General Discussion

Hey, I'm glad you liked it and got something out of it. Once I got my band saw rigged up it has really become an integral tool. Funny about my anvil, I don't really notice the wobble until I see it on video. It is very solid with downward strikes, its just the lateral hits that make it move. I am going to route some feet on to the next time I go out there, maybe that will help it. Thanks again, -

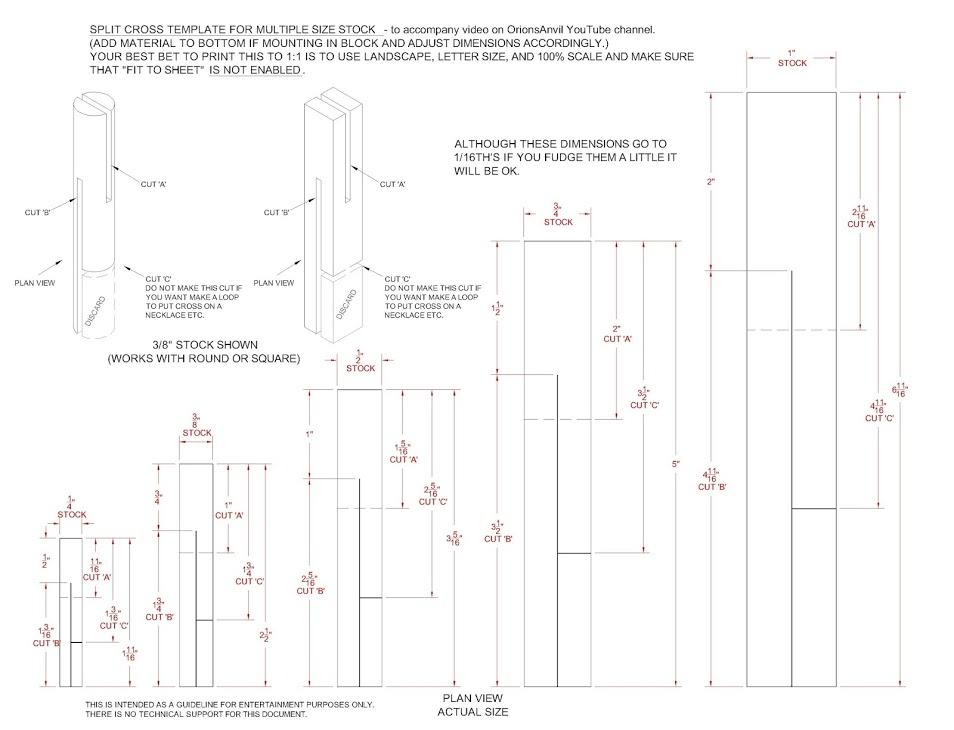

I know there are plenty of Split Cross/Fredricks Cross tutorials. But I actually had a request so I did a quick one on how I do it. I also included a template that I made to scale up or down a few sizes from 3/8" stock, thought someone might find that useful if not the video. And yes, I know I need to get that wobble out of my anvil stump. I keep forgetting about it and its aggravating me, I'm not forging anything else until I do that.

-

I didnt know anything like this existed anywhere but I checked out that site, pretty cool stuff. Thanks There is a cool pic here: http://www.scotforge.com/Learning-Center/Metalworking-Alternatives

-

I couldn't see where this had been posted before, maybe I didn't just miss it. Thought ya'll might like it. This kind of stuff just amazes me.

-

That's a tough one, prayers sent.

-

I made a fishing gaff and bending jig.

norrin_radd replied to norrin_radd's topic in Member Projects

She be destined for Davey Jone's locker matey's Yup, like a rock Oh well, I'll figure something out. If I get the gumption up to try another one I may try a hollowed out handle and some foam or great stuff maybe. -

Very cool, seems like it needs a motor and some zombies though

-

That is really nice. These are definitely my favorite anvils.

- 39 replies

-

- American Star

- Trenton NJ

-

(and 1 more)

Tagged with:

-

I made a fishing gaff and bending jig.

norrin_radd replied to norrin_radd's topic in Member Projects

:) Yeah, more than likely I'll be doing some retrieval from someone's cow pond. Thanks for the comments and input guys. I'll have to check into some floatation/retention mechanisms if it don't float. I'm pretty sure it will be used mainly from the bank but that doesn't mean it wont end up in the drink. Thanks for the gaff profile tip too Frosty. I had looked at several pics to get an idea, the eagle claw makes perfect sense. And I will have to come up with simpler way if I make anymore, that was just an idea that I had turning in my head for a couple of days. At least it motivated me to make a bending jig that I may can use for other stuff. -

Very nice, the contrast is just right.

-

I made a fishing gaff and bending jig.

norrin_radd replied to norrin_radd's topic in Member Projects

uh..hmmm... I totally didn't think about that. I'll have to check but I got a bad feeling about it. Thanks -

My dad asked me if I could make him a gaff to help him out when he catches catfish. Usually eatin size ones in fresh water ponds. So I gave it a shot. I'm pretty sure I made it way more complicated than it needed to be but what the heck, it beats mowing the grass. Used 5/16" rod and treated pine handles. The handles are like knife scales on the t-handle loop. You can kinda see the "full tang" aspect of it in that bottom pic. A while back I got some blue wood stain to fool around with so I tried on this, I think it came out pretty cool. I really didn't know how to make one so I made my very first bending jig too. Used it on the handle It was absolutely not necessary but I posted some short vids on these just because I like wasting time editing boring videos.

-

I will have to try this, make them easier to find in the grass too.

-

Thanks, I have a BUNCH of these things. Should be fun forging for a while. I think the next one I will do a vid on is a karambit like this one I made a while back, but with a handle and an edge. Sure wish I could post a link to the heat treat and function test of that throwing knife here, it just does not like it though.

-

Taking a hobby to a business

norrin_radd replied to SnailForge's topic in The Business Side of Blacksmithing

Sounds like you got a pretty good handle on things snailforge. straightrazorplace.com helped me a great deal when I started using straight razors a few years ago, great forum. -

Tried to post link to vid but it wont take. Guess there is a limit or something.

-

Great pattern on that blade. Does the same thing apply to band sawmill blades?

-

I finally got to see the show and I enjoyed it very much. I was actually able to watch it with a room full of my extended family and everyone seemed to enjoy it. That doesn't happen often. I liked the contest aspect of it. Interesting to see how people with a lot of skill and talent deal with guidelines and the equalizer of the clock. Even pros make mistakes. I ditched my dish a while ago so if its not free on one of the streaming Roku channels I have to buy per episode or season, this first episode was good enough for me to consider buying the next one and possibly the season.

-

This is the second throwing knife I have forged from a hay mower blade. Posted about it http://www.iforgeiron.com/topic/42348-forged-throwing-knife/?_fromLogout=1&_fromLogin=1 I have a final video showing the heat treat and how it throws but at this time the forum will not let me add a reply to that post, but its on my youtube channel if you want to see it.