-

Posts

256 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Davor

-

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

Something like that, with the handle for steering. But maybe an axle where just the wheels pivot. I think the table will be wobbly if the whole axle pivots even if that would be the easier to make. I'm still thinking about it. -

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm either making castors or I'm leaning to some sort of like a wagon stile with basically two axles where one can rotate. -

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm going to make a table for the yard, steel base (probably). But I want to be able to move it around. So I made some wheels. Not the most common thing to start with when making a table. -

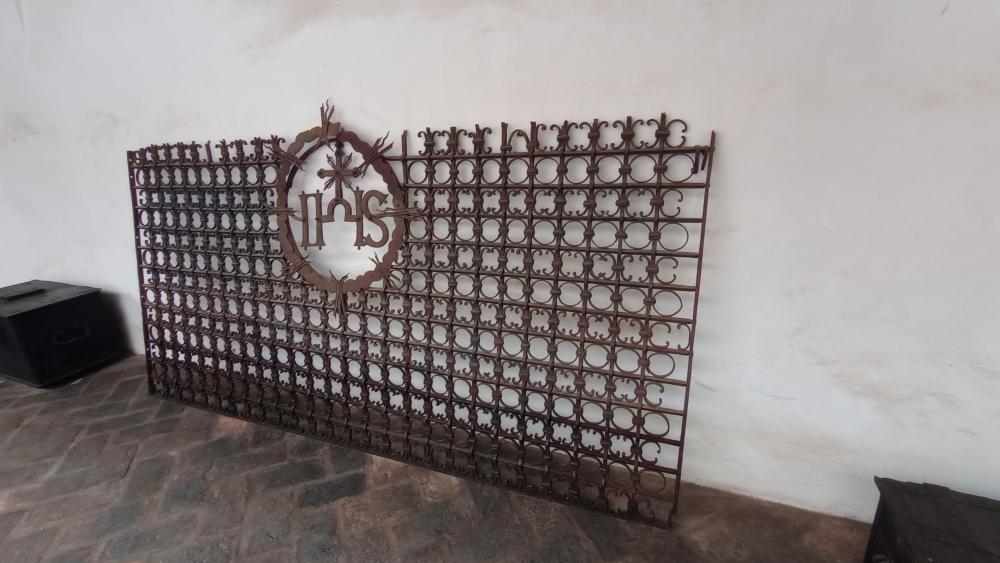

Yes it is from a museum. The barrel is also from a museum, it is vine making exhibit. The large hole is for cleaning the barrel.

-

Varazdin, Croatia. I found the plug holder on the barrel interesting usually they are also made from wood.

-

And there it is. Thanks Frosty. Now it seems obvious.

-

Well it's not my anvil but I wouldn't want to start a new topic for a potentially a stupid question. I'm on vacation and there is little bar called Old Forge (closed at the moment, it is still out of season), there is an anvil for decoration. I thought that the holes for moving the anvil mean that it is a forged anvil and the absence of the holes that it is cast. Now this anvil has legs that look cast but also has holes. What am I missing?

-

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

Whaaaaat? Quit your day job because you are a natural at this. Keep at it, we will follow your development with great interest. -

What's your latest blade look like? Post em and let us see.

Davor replied to HondoWalker's topic in Knife Making

Made a butchers knife. It is a bit too big for deboning chicken drumsticks. But that was the task at hand. -

That potbelly stove is beautyful.

-

Thank you Irondragon, but after googling blacksmith memorial bouquet I don't think it would work.

-

Years ago I used to work as a mechanic, fixing heavy trucks (not cars). And I found this knife on the engine jammed in between the heads. I'm guessing that whoever worked on the engine before lost it there. I have no information on it, but it is obviously forged. I cleaned it up and sharpened it and just used it in the kitchen today. The fuller is just on one side.

-

So I made a small one. Unfortunately the spar broke when I was widening the hole so it is welded and I should have made it a bit bigger. I like the big one more. But I do like this theme, maybe I'll explore different ship designs.

-

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

That is a nice hook Billy. JHCC that is a genius design, I was looking at it thinking how that lever looks funny how are you gonna hold it shaped like that. Then I realised that it is not for pressing down, that it holds it self. Excellent. -

I went down the rabbit hole of viking ships, because of this debate. And if Viking ever made a two spar mast it would look like this. https://www.eldjarnbaat.no/index.php/byggeklipp?id=16

-

This topic will be little treasure trove of curiosities. Here is my little collection of French wrenches, that is how we call them here, the T shaped adjustable wrench. The three on the right side are rescued from the scrap yard and needed to be fixed. The small one I bought on the internet. That leaves the second one from the left, my grandfather gave me that one, and he inherited it from his father in law - my great grandfather, who at some point punched in his initials with a center punch.

-

It was fit and cut. First I made the big bend or I should say bow and tok a piece of cardboard just to see how to bend the ends, and that was also just a ruff estimate. And it was done cold, so I was able to manipulate it a lot easier with hands and hammer than holding it with the tongs.

-

Thanks guys, maybe I'll make a smaller one with one spar.

-

Thanks George. I know about the one spar, but it didn’t look good, to me at least. Because without the sail it is a lot of empty space.

-

-

From 1991 to '95 we had a war here in Croatia. In '91 I was 9 years old and during the heavy fighting hundreds of us kids were sent to Czech Republic until it was safe to return in our little town, I was there for about 5 months. I bought this little knife there and gave it to my grandfather when I got back, he died two years ago and so then I took it back. It is Mikov brand, Czech made company.

-

I got some items but this is what I got a picture in the phone right now. It is a CZ motorcycle 175cc two stroke. My father bought it new in 1973, few years back I restored it. My father rode it, my grandfather rode it, I ride it and hopefully one day I'll pass it on to my nephew.

-

So it is a hammer. What is the difference between it and a normal hammer? I'm not going to use it I have other hammers, I'm just curious.

-

The first picture is the pein, viewed from the top. It is also mushroomed.