-

Posts

172 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by tjdaggett

-

Morning, smiths. We learned this weekend that my grandmother, who has been successfully battling stage IV ovarian cancer for just shy of three years, has contracted c. diff. On top of that, my grandfather has just been diagnosed with COVID-19, though it is mostly asymptomatic. They will have to quarantine for a total of about three weeks, during which my grandmother cannot have her chemo treatments. My mom informed me a few minutes ago that when grandma went in for hydration this morning they took her straight to the ER. She's in rough shape. We've gotten grandma for much longer than we expected. She has two more great-grands than she had when she was diagnosed, one of them mine. If it's her time, it's her time. I'd love prayer for healing, but also for peace for my mom and my grandpa if grandma passes. Those two will be hit the hardest. Thank you all.

-

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

I just about choked on my fudge-sicle. That was a good laugh. JLP, that is the coolest thing I've seen all day. I look forward to seeing what becomes of it. -

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

JHCC, I like your thinking. -

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

*tips hat* The dirt floor bit is more bringing in a bit of gravel, leveling the space under the shed decently. -

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

I just took my ten minute break and began moving shop detritus into the garage. Once I get everything out, we can move the shed out from under the maple tree, put in a chimney and a dirt floor, and transform the detritus into an fully operational battle st... I mean forge. -

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

Helena, that was a fantastic idea. I think melting down the thing that almost took your hand and making it into something beautiful is one of the most smith-like things I've ever heard. -

Cool beans. Thanks guys.

-

Happy Friday, smiths. I'm thinking about my chimney. It currently exists only in my brain, so there are no pictures. Here's the setup: - The forge is an old bottom-blast rivet forge with a Buffalo blower - My shop is a 10' x 8', plywood walls - The doors do not seal at all; wind does not blow through, but it's drafty - I live in Minnesota and hope to forge primarily during the winter; the air outside the shop will be cold - I plan to use mainly charcoal for fuel, but I have access to cheap coal through my local guild - My chimney will be 10" diameter, about 9' long, with a fairly close-set hood So, the question: do you think I'll be able to get a solid draft with the doors closed? Do I need to worry about burning up all the air in the room, or will the hot air going up the chimney pull in fresh air from the open seam of the door?

-

That's the storage plan. Unfortunately, my fire size is limited to 3'x3'. Maybe I'll design a retort to fit that exact requirement someday.

-

We got the third batch out on Sunday. Two coffee cans full of wood, cut to length by my bride and her chop saw. They came out crispy, hard, and shiny. As expected, the punky wood makes less dense charcoal. Next batch I'm going to try using three cans, and I'll be weighing them before and after. Kelsey and I think we might be able to do four cans in our fire circle, but we'll see. My brother-in-law is also putting in a few cans when he and my sister have backyard fires, so I'm going to have to upgrade my storage pretty quick.

-

Bravo, Cleave!

-

That's interesting about the coal/coke split. Airflow?

-

Which is more valuable to you: time, or money? If you have time, I would second IFC's charcoal-making suggestion. I also know that Glenn often (exclusively?) forges with wood. I thought about doing the same, but wood forges put out a lot of radiant heat and I'm going to be working in a pretty small space.

-

Frosty, I was able to give a couple of criteria that he used in his shopping: - Cut through pieces of metal at least 1" thick (not quickly) - Shape/grind steel I most DEFINITELY said thank you. Thanks to everyone else for the safety advice. I do not come from a handy background; circular saws are the outside of my comfort zone. I will definitely be studying the manual before use, and even if my GREAT-aunt tells me to take the guard off I will stolidly refuse.

-

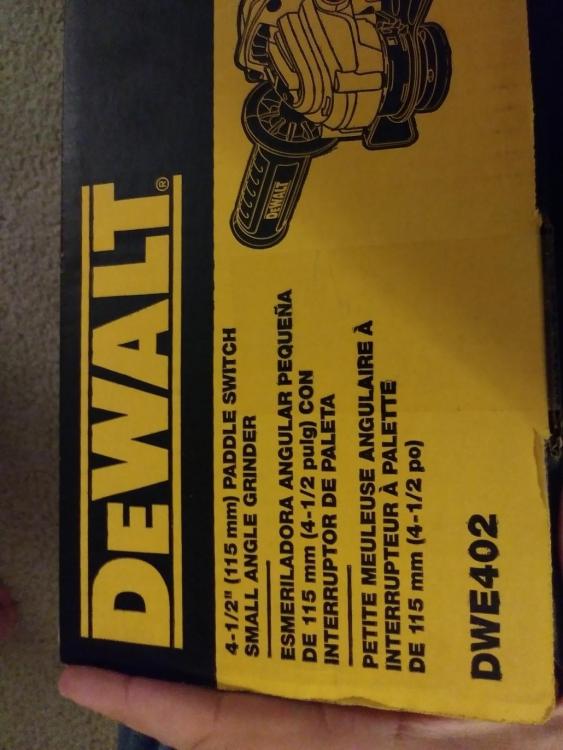

Smiths, I was given an angle grinder for my birthday. I was vague with my birthday list, never having used an angle grinder before. I have not had time to research them, nor to test this one out. My father-in-law is a very handy person and did the research on this one, so I'm guessing it will do what I need it to. There is a limited window on returns, so I was hoping you might be able to lend me the benefit of your experience and confirm: will this do the job as a general-purpose angle grinder in a hobby shop? The details of the grinder are in the pictures below. Little Bean for scale (apologies for the blur).

-

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, we'll get her there one day. For now, she limits herself to quiet, gracious statements like, "Would it be easier if you did ______ instead?" -

FeyWest, I apologize for the slow response. I apparently haven't checked my email in two weeks. I live in a suburban neighborhood and I have a fire pit and a woodpile. My neighbors therefore share with me all kinds of wood. The original trees in our area were silver maples (the one in our backyard is the largest I've ever seen) and they are starting to age out. As people cut theirs down, I've been rolling a few rounds back to my house and splitting them. We've also got crab-apple wood (I offer it to anyone who smokes meat first), lilac, white mulberry, and soon oak. Right now I'm working through my punky wood pile. Summer is garden time for me, so I haven't made much progress yet. I figure that if wet, moldy stuff will pyrolize and get metal up to welding heat, the good stuff will be even better.

-

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

Thank you Chris and IFC! I put up a separate post with more pictures that goes into that a bit more. This is an ad hoc setup, more proof of concept than anything else. The first dream is to have a setup tailor to my height. The second dream is to have one that somehow accommodates my 5'4" bride as well. -

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

I don't have a great picture of the "finished" product, but I did my first forging this weekend. My goal was to set up an outdoor workspace, get the forge lit, and see if I could heat metal. I ended up making something resembling a fire poker. -

What did you do in the shop today?

tjdaggett replied to Mark Ling's topic in Blacksmithing, General Discussion

Does the draw knife draw? It looks excellent. That might be a good one for me to work towards; been needing one. -

-

Disclaimer: if this is too many photos, or if they are too large, let me know and I will size them down further. I don't have a good idea yet of the resolution/KB that is too much. Hello, smiths. I was recently given a good birthday gift: the time and space to assemble a make-shift forge, light it, and forge. My sister and brother-in-law brought dinner, allowing my wife space to take care of Little Bean and take pictures, and my brother-in-law manned the blower so I could do less first-timer multitasking. The setup was put together in about twenty minutes. The metal bucket is full of dirt to make an adjustable-height, fire-resistant stand. The white bucket holds the charcoal. My BIL and I alternately used my hammer and a scoop to work the fire. Note: my long-term setup will be in the white shed, but it needs to be moved out from under the maple tree, and the pandemic has diminished my labor pool (D&D brothers). Things Learned: - My anvil is much quieter than I anticipated. - My homemade charcoal produced almost no smoke once it was up and running (smoke picture was in the first five minutes). - The face of the anvil and the top of the forge both need to be elevated; I'm thinking 8". - The stump--not my first pick--is too wide. It kept me farther from the anvil, straining my back. - My little blower is not only capable of creating welding temperatures, it can burn steel. - My daughter, who watched from a distance, is hypnotized by forging. - My wife is a natural at taking forging pictures. Final note: I know I should not learn forging on rebar. My stock needs organizing badly. I would value your thoughts, opinions, commentary, and glowing compliments on my lady's photographic skills.