Sprig1

Members-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Sprig1

-

Thanks Njanvilman and Frozenforge I just went out to the shop and checked it looks like a zero. Thanks for all the help. I'll stop bothering you now. Now I just have get out and use it. I took it off the stump and mounted it on my anvil stand. I hope to get up to the museum this summer. Or I might see you at the abana conference this summer. Thanks again Chris

-

Hi Frosty,VaughnT and Njanvilman Thank you for the advice it will be followed. I couldn't believe it when I saw it. We started discussing it and I'm telling him how much it's worth and how the anvil market has gone crazy. Then he says I don't want that much for it and sold it to me for a great price. Their are nice people in the world. It was his wife's fathers anvil and she remembered playing around it when she was a child. They where probably in there 80's. I told them I would try find the date of when it was manufactured. Njanvilman that would be great if you could find the date it was manufactured. I flipped it over today but I couldn't find any numbers. Are they super small? I hand wire brushed it. I have talked to you before about coming to your museum but just haven't made it. I met you down in Maryland at Bill Kichners (sp) hammer in. Thanks for everything Chris

-

Hi I was buying a metal band saw and they had this nice fisher anvil there. I ended up buying both. The wife is being very understanding . I'm guessing it's built after 1896 from what I've read. Do you think I should dress the edges more I think I should. It would hopefully take out some of the chips and stop future ones hopefully. Any thoughts. I live in Maryland. Thanks Chris

-

Hi Glenn and 781 thanks for the response. I'm trying to do it cold. I will try the bending jig in the vice and keep it flat. I didn't keep the tubing flat the first time I tried to bend green house arches. I have quite a few of these to build. Thanks again Chris

-

Hi I'm trying to bend round rings out of 5/16 inch round stock. I'm making trellises for a garden. The sizes would be from 8 inch to 30 inch. I tried my roller for flat stock. The kind that has 3 rolls and groves in the ends of the rolls. It made the rings but is destroying my roller. A friend has a wagon wheel roller but I haven't gone to get it yet. Does anyone have any suggestions. All the rollers I see only do up to 1/4 inch. I would like to make more then a few these. Thanks Chris

-

Thanks Arkie for the reply. Will give it a go and see what happens. Sorry all about messing up the title

-

Hi all I have got some chunks of iron and would like some help identifying them. They came from northwest Connecticut. My friend was digging with an excavator and found them. I know a furnace was on the property from a long time ago and a blacksmith shop.They where going to get scrapped so I brought them home. Just wondering how they where used and what type of steel came out of them. I am not going to try to melt them down I don't have the experience or knowledge or time right now. One is about three feet long the other two feet long maybe three inches wide. thanks Chris

-

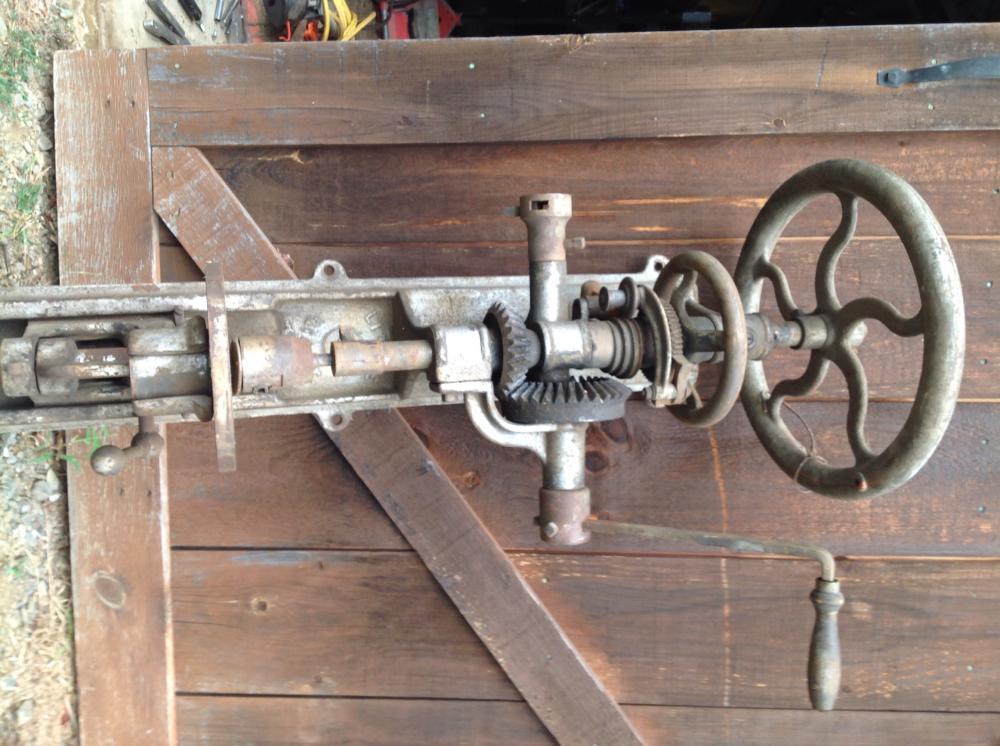

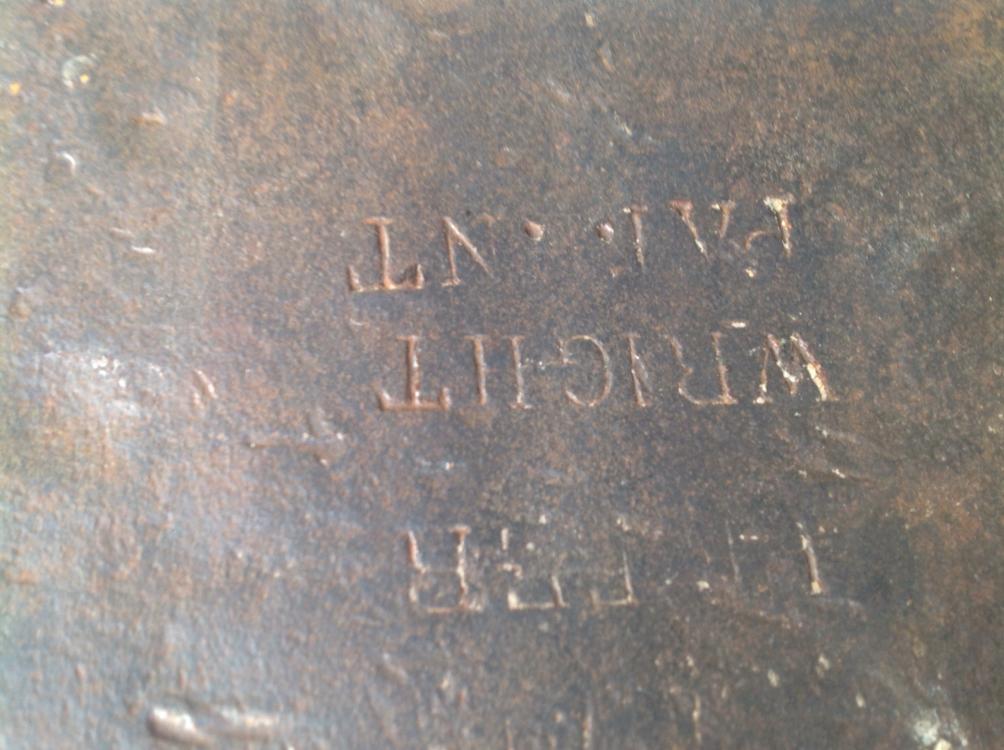

Wells Brothers post drill 4 little giant

Sprig1 replied to Sprig1's topic in Drills, Post drills, Mag drills, etc

Thanks all for the responses. I will see what I can find. Thanks again chris -

Wells Brothers post drill 4 little giant

Sprig1 replied to Sprig1's topic in Drills, Post drills, Mag drills, etc

Hi Matto thanks for the response. What search on Craig's list did you use to find them? Yes I have to get it cleaned up and start using it. I never had heard of a Jacobs Chuck will have to research that where do you find them. I have not looked yet so probably should will do that tonight. Thanks again Chris -

Hi I am trying to rebuild a 243 or 43 buffalo coal forge. I think that's the model. The fire pot doesn't seem to fit and someone cut the sides. Basically it looks like I need a new one. Can I build one? Could it just be steal?There is a gap around all the way around. Hope the picture helps thanks Chris Could someone tell me why all my pictures are up side down they aren't that way when I download them thanks

-

Anvil identification and comments

Sprig1 replied to Sprig1's topic in Anvils, Swage Blocks, and Mandrels

Thanks Stan how's life in Australia looks like the economy is slowing haven't been down there in four years. I lived in Victoria for a year in the early 90s had a great time. -

Anvil identification and comments

Sprig1 replied to Sprig1's topic in Anvils, Swage Blocks, and Mandrels

Thank you for replying. I couldn't find anything on it. It is probably the best of the lot. All the others look like they need some help. Someone more skilled then me to weld on them. Thanks again chris -

Hi I have a few anvils just getting started. What do you think this one is it says England 45 kgs on the other side 100lbs nothing else. It seems to be cast and brand new. The other is a mouse hole 1 / 1 /14 pretty beat up I use to use it on the farm to straighten things. The other is a peter wright can't find any markings for the weight probably 180 lbs. The edges are a little beat up top swayback. They all should be good enough for who they are for. I just about have my shop done just finished putting metal on the walls its small but a start. Thanks chris sorry about being upside down pictures. iPads must not be for left handed people. They are not upside down when I look at them

-

Hi Thomas I ment rail good catch. I have plenty of ties

-

Thanks for the reply. I didn't do to bad he Through in 3 feet of railroad tie with it. My sister is starting a tinsmithing shop so I will clean it up for her

-

Hi rescued an anvil got it for $10.00. Says pat March 26 1895 12 inch long 3 inch wide and 6 1/2 inch tall probably 10 or 15 pound. Trying to identify it. 1st time trying to post pictures don't know why they are up side down. Thanks Chris

-

Power hacksaw craftsman 108 1502 feed teeth

Sprig1 replied to Sprig1's topic in Saws, bandsaws, hack saws, etc

Hi Michael thanks for the help. Much better diagram I need Gbf 140 and they are available thankful for small things. Better price too 4 dollars verse 160. The manual even said how to adjust them. I got 10 blades for $10.00 so I figured So I better resurrect the saw. Fell on the ice hurt my shoulder at work so my blacksmithing is over for a long while. Thank again and hope you had a good holiday chris -

Power hacksaw craftsman 108 1502 feed teeth

Sprig1 replied to Sprig1's topic in Saws, bandsaws, hack saws, etc

Hi Michael thanks for the response. I tried the Sears web site and didn't see them there. It was really hard to see there parts diagram -

Hi looking for the feed teeth for a power hacksaw. It's a craftsman model 108 1502 I think made by Covel manufacturing. They look replaceable they are ment to be turned over to get a new edge all edges are broken. Would they be made out of machine steel? Thought about making them. Sorry no pictures have to work on that. Thanks Chris

-

Hi I have been a member since August 2013 never posted before but have read a lot in the forums. I am putting together my shop now. My father was always going to build one but never did and a friend that has a lot of tools to.Have a three burner propane forge, anvils, tongs,coal forge,post vices,machine vises. I am a very lucky person and blessed. I am building a very small shop now and can move into bigger one if I need to. I have done a lot of farmer welding not pretty but holds together usually. I will post some pictures sometime when I figure out how. I am a total newbie at blacksmithing wondering if there are any other blacksmiths the area. Thanks in advance