-

Posts

64 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by PaperPatched

-

-

On 10/23/2021 at 1:30 PM, DHarris said:

It's a broken-off oil cup. You can get one from Mcmaster-Carr (Commercial link removed per TOS) and others. You would not necessarily fill to this level, or you will probably have a lot of leakage. A smaller amount in the bottom of the casting (that the motion of the gears can distribute) will probably serve you better.

-

It's used to balance the heavy metals in bananas. See : //ir.unimas.my/id/eprint/17734/

-

On 12/11/2020 at 11:17 AM, ThomasPowers said:

Has a certain "Lewis Carroll" feel to it.

Or Lewis and Clark

-

Good Guess based on shape. But I should have included something for a sense of scale. The U-shaped opening at the top is only approx. 1-3/4" x 1-3/4". And the total length is 7-3/4".

-

This object came in a mixed lot of metal scraps given to me. Can anyone identify it ? The bottom two projections end in dull points. Thanks, Alan

-

And why not incorporate the boric acid treatment along with the charing ? Char it then boric acid (available at any pharmacy here (Chemist across the pond)). The boric acid comes as a powder - dissolve it in water and apply.

Link to information about borate: http://www.americanborate.com/all-about-borates/borate-applications/borates-in-flame-retardants/

What about the borax we use as flux ?

Alan

-

Walking the plank is not.

-

Thank You. And what could be a better wedding anniversary present (June 7th) !

Alan

-

Despite experiencing 42 degree (F) overnight temps while tenting during the 2017 NEB spring meet, my wife said she will go with me to the 2019 spring meet on Cape Cod. However her boss is asking for vacation dates already and there is nothing to be found on the NEB website calendar. Have the dates been settled yet ?

-

On 12/8/2018 at 5:34 PM, marcusb said:

What mill and lathe are you planning for Paper Patch?

If I knew more about rebuilding I might look at a used Monarch, but the lack of that skill plus the size problem has lead me to look at imported lathes. The brand I've spent the most time investigating is Precision Matthews ( precisionmatthews.com ). I keep succumbing to the features list of the next most expensive model and thus bracket creep keeps raising what I'll have to pay. In a way it is a good thing that I won't have the carport enclosed with a new poured floor until late next year (more time to save up). I'm now waiting for my electrician to pull wires so I'll have 240 volt electricity in the newly remodeled 1938 garage. My wife says I can use it for 5 years as a blacksmith shop. And that 5 years should be enough time to build a large shed to house my blacksmithing gear (she wants to be able to finally park a car in there and escape removing ice and snow in our New England winters).

-

I read that you are leaving a 6' x 10' area for a lathe. I'm also in the planning stage for that. From what I've read on the machine tool forums the average time from buying a lathe to buying a milling machine is about three months ! You may want to reserve a bit more room.

-

On 10/4/2018 at 10:10 PM, ThomasPowers said:

Ordinary Ordnance Ordinances to be sure. Cities are fussy like that!

Are these in numerical order ? making them Ordinal Ordinary Ordnance Ordinances ?

-

Average Joe buys the clear PVC cement and calls it good. But, if you look in the section where the PVC cement is sold you will also fins PVC cleaner, and you will find PVC Primer. The best joints are made by cleaner, primer, then cement. You can often get away without the whole process, but sometimes you won't. Not saying you're not above average

. You just may not have known about the whole process. No one knows everything about everything.

. You just may not have known about the whole process. No one knows everything about everything.

-

Registered online for Saturday.

-

Glen, I think you are right about power tool interference to Bluetooth being too small a problem for manufacturers to worry about. As it is the level of background "noise" increases all the time. The FCC is charged with dealing with radio interference, but is so strapped with bigger problems that this problem will probably never see any attention. The switching power supplies in LED light bulbs and other consumer electronics are posing quite a problem for ham radio (Amateur Radio). Manufacturers seem to pay little attention to complying with FCC regulations, and the FCC is so under funded that they cannot deal with it all. I'm no expert at radio interference so don't know if there is any practical way to deal with it in regards to Bluetooth. The size of Bluetooth devices makes conventional avenues such as shielded cables and wrapping cables through ferrites impossible (at least at my skill level).

Alan

-

The first radio transmitters were arc based. And I think that I read that they are now banned due to the wide splatter of frequencies they output (there was no one else to share the spectrum of radio frequencies with back in those pioneering days). Every time you pull the switch you are creating a local radio transmitter. I don't think there is any practical way to prevent the Bluetooth interference.

Alan -- K1ALN

-

2 hours ago, Will Taylor said:

.....and they are used to uniform primer pockets on cartridge brass

I would not go anywhere near a primer pocket with a center drill. Primer pocket uniforming tools come sized specifically for primer pockets (large and small), are flat bottomed, and have a shoulder to control the depth of cut.

-

Elegant leather work to go along with beautiful knives !

-

Ah, you bring back memories of the sixth grade and the hiss and steam when boys would try to quench the steam radiator in the bathroom on a cold New England day. While I never contributed to the effort the attempts of others made even a brief excursion into the bathroom extremely unpleasant.

-

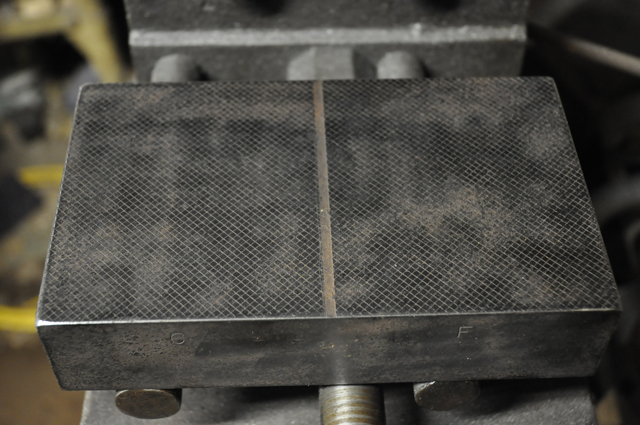

Thanks everyone for the replies. I've scrapped my plans for a thick bolster plate and will oil this well and put it with the "might be useful later" items. As to being less flat for the cleaning I might have chosen electrolysis if I had any inkling of what the block was, but as I said above there was so much rust on it that the cross hatch was invisible (which made it not flat in and of itself). I have carbide scrapers and a small surface plate in pristine condition, but restoring the lapping plate has too little reward at the present.

-

I stopped at yard sale this past weekend and as I was leaving I explained that I was learning black smithing; and asked if there where any heavy pieces of metal around. The home owner said "just a minute" and disappeared around the corner of the house. He returned with a steel block and said to take it gratis as he didn't want to take it south with him. The block measures 4-3/4 x 7-3/4 inches and had a moderate coating of rust. At that time I couldn't see any printing or cross hatch pattern. But when I went over the block with a zirconia flap disc I could see the letter C on the sides of one half of the block and the letter F on the faces of the other half of the block. Turns out he thing cleaned up really well. The disc removed the rust and revealed the cross hatch pattern on the top. The thing is hard enough to skate a good file. I going to venture a guess that perhaps the block was used with some kind of abrasive slurry to sharpen something. Does anyone know what this is and was used for?

-

Here is a link to a very informative article about testing for Lyme disease and its possible relationship to other diseases:

Click the right pointing arrow in the circle, located on the bottom left of the image to start the program.

-

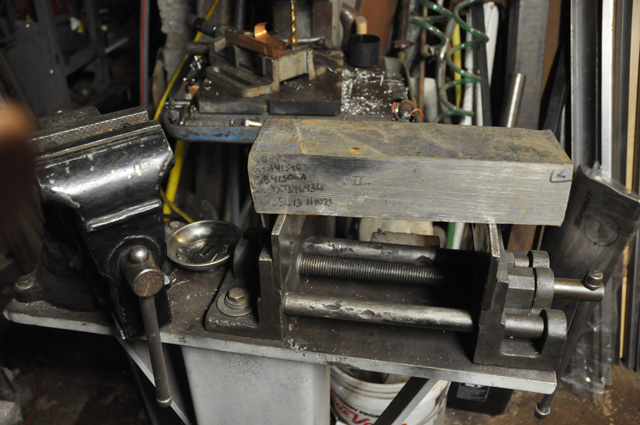

I found this bar/block of steel 3" x 3-1/2" x 13 inches at a scrap yard yesterday and couldn't resist at 20 cents per pound. I have not tried any spark test on it but as you can see in the photo it has some numbers written on it, a lot probably relating to some job. I can make out AMS 5643 and H1075 . Researching on line these leads to information on heat treating 17-4 stainless (one hour at 900 degree F and air cool yields Rockwell C 44). The steel is magnetic, but noticeably less so that the jaws of the vise to the left. It was sold to me as generic steel rather than stainless which would have been five times more money. It would be a rare thing for this yard to miss identify some steel. I think it looks like a vertical portable anvil once a base is fabricated Any thoughts?

-

Mikey,

The Ceramic Shop dot com in Norristown, PA has the 4" x 6" kiln shelves. I just looked and their smallest is 2" x 6"

Alan

As tactically as I could represent for my taste

in Folding Knives

Posted

Elegant !