edennis

-

Posts

115 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by edennis

-

-

That all makes sense. I find it interesting though that in the previous burner configuration (close to a right angle pointed down), there was zero vibration.

-

...almost. Now it whistles instead of rumbles. But that makes me feel a little better.It does get screaming hot though. I adjusted the richness of the flame, btw.

I'm a little stumped by the harmonic problem still. I think it must have to do with changing the burner from a right angle to a tangent and then interfering with itself and amplifying (circular motion= less turbulence?).

-

That was an easy fix. Turned out the kiln plate in the bottom was causing the harmonic. Took that out, no more vibration.

-

The sound is not dependent on the richness of the flame. The video really doesn’t capture the intensity of the vibration. I am closing it all the way. I guess I may play with adjusting the burner position while it’s running. When you say butter, do you mean wet with water? I did do that, and let it dry. If it all falls off I’ll just try again I guess.

-

I thought I'd write an update on this propane forge and ask a question to those who might know:

It's been 5 years since I finished this forge and although it still reaches forge welding temperature (albeit more slowly than at first) I finally had a moment to reline and revamp it. So I did that. I think 5 years of use is a pretty good return.

I relined with new kaowool, rigidizer, kast-o-lite 30, and merikote (the merikote seems to just fall off though, not sure how to get that to really adhere.)

I also moved the location of the ribbon burner so that it is coming in from the side and at a tangent to the outside edge of the interior with the hope of creating a hotter and more reducing environment.

I also created an insulated weighted door which I can open as you can see.

QUESTION: When I go to close the door while running there is an intense, low, vibration that gets louder (much louder than you can tell in the video) as I close the door. It's quite disconcerting to the point where I question if it's safe when the door is all the way closed. If I remove the soft bricks covering the back "door" is helps significantly, but I'd rather keep that heat inside. Why is this happening? What can I do to prevent it? (see video)

Any advice would be appreciated.

Video is here:

-

I figured I might need to re-adjust it. I wanted to see how close I could get it with the old blade while using it as an opportunity to get to know the machine.

-

I ended up ordering a new bimetal blade off mcmaster carr: 8tpi seemed to fit the stock sizes I'll most likely be cutting. I'll compare prices with the site you gave Frosty and order a few more, thanks for the lead. On my smaller saw I've used for the past 4 years I always had an extra "in stock", ready to throw on when the old one broke. I'm hoping the larger blades wont break so often. On the smaller saw I was going through 3/year approximately.

The auto shutoff works great. I did order some coolant, so we'll see if I ever use that. Right now the blade is cutting wedges, which is pretty frustrating. I tweaked the guides until they are as close to square as far as I can tell so at this point I'm assuming the problem is the old blade that was on the saw when I got it. I'm hoping the new blade will solve that issue. Otherwise, I'm hoping the problem is not worn out carbide guides.

-

Thanks for expanding on this. I did make a different post specifically on the blade tension. But all of this seems like great info. Thank you.

-

Thank you for the thoughtful reply.

I ordered a new blade, so I'm going to start there and keep your tips in mind.

-

How tight do you go on your horizontal bandsaw. I just upgraded to a 10"x16" capacity saw with a 1"x132" blade. I've heard to tension until it rings when plucked, but that feels like I'm putting too much strain on the machine to get to that point. How do you know when the blade is tight enough?

Thanks,

-

Does anyone have tips on setting the blade tension? Someone told me to tighten until the blade rings when plucked, but I can't seem to get it that tight and I'm worried I'm putting too much strain on the machine.

-

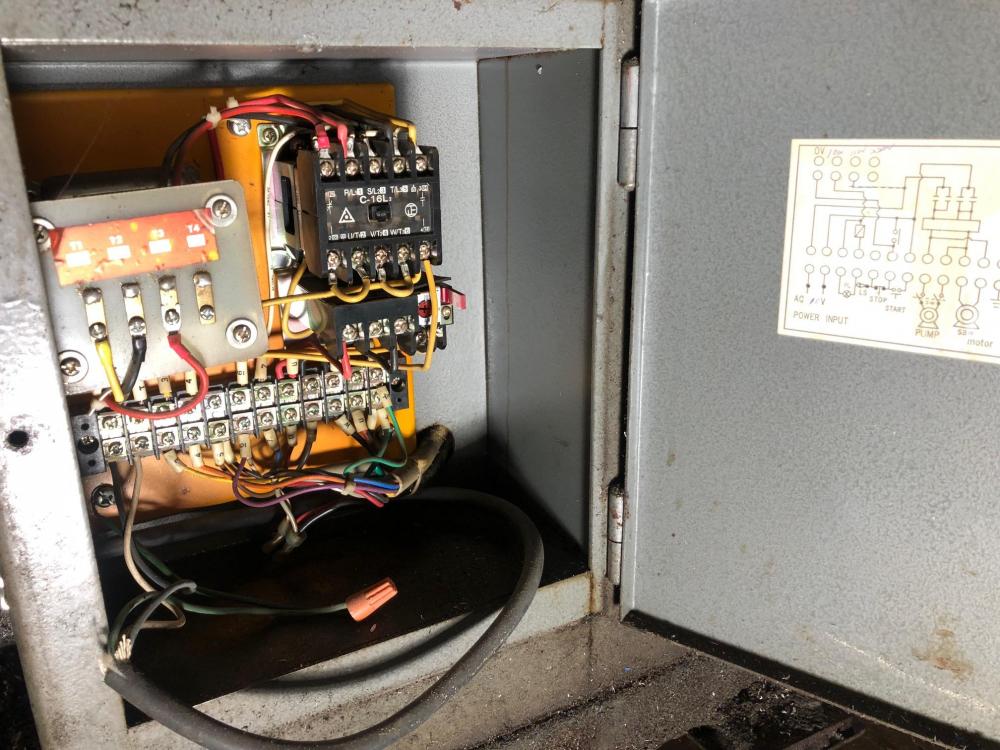

Neat, thanks. I might write back to ask some more specific questions on the electronics. The previous owner didn't use the coolant pump so I need to figure out how to get that going. It seems beefy for sure. Nothing seems flimsy on it and the bolts are large, which is my kind of machine. The true test will be in the performance, however....

-

That wire hanging down appears to be the ground. Looks like someone cut the wire too short at some point.

-

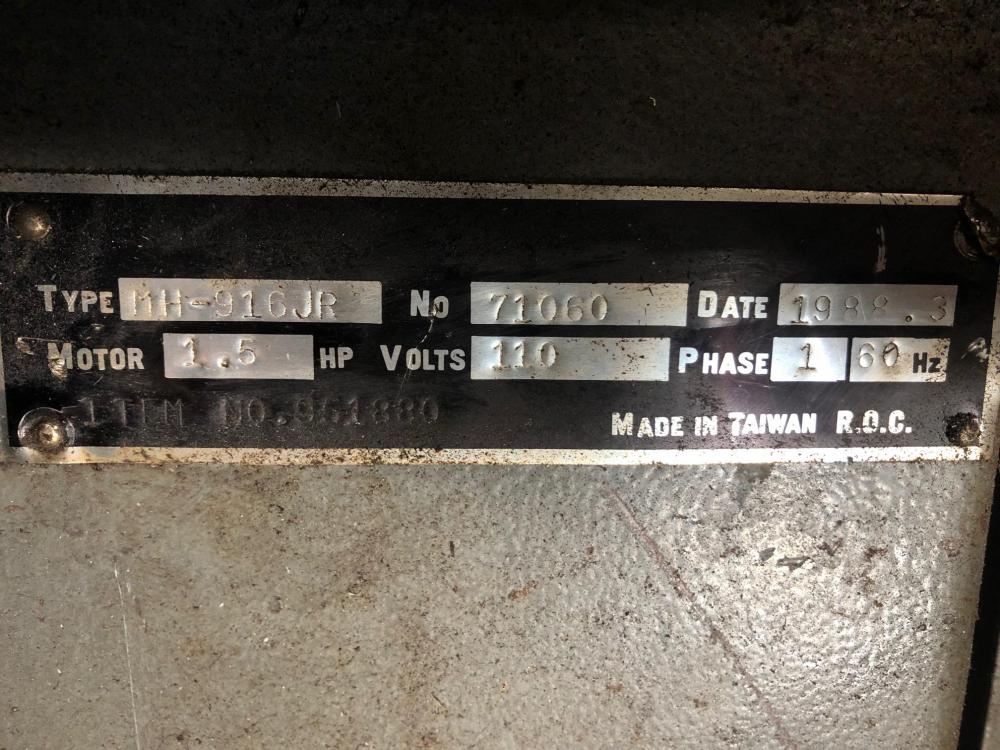

Yeah- this model certainly is not made anymore. I got the saw in the shop and poked around it better. There's a plate with some numbers. It looks like it was likely manufactured by a company called "Vectrax" in Taiwan. This is, I believe, the newer version of the same saw: https://www.mscdirect.com/product/details/09518853

All the electrical stuff is routed through a crazy panel underneath the saw. Is that normal for these older bandsaws? It seems overly complicated, but I also don't quite understand all the wiring. I'll attach a photo.

-

It seems pretty solidly build, but is certainly well used. I saw the saw today and couldn't find any manufacturing information at all. Guess I'll find out once i get it in the shop.

-

I did the same search and found almost no information on the MSC brand bandsaws.

-

-

I bought a carbide burr off Mcmaster-Carr and it cut for a while, but seemed to have burned up and dulled far sooner than I expected. Any tips on grinding on stainless (304) with a die grinder? Should I have been goer slower?

Thanks,

Eric

-

It is a copper tuyere and lasts a very long time as long as air is running through it.

-

-

Ah, I understand. I'll look more into that. Thanks.

-

Yes, I have baffles and can close off either forge if not in use. I'm not familiar with the use of inducer fans for a forge. Would it be mounted somewhere inside the chimney?

-

The forge on the left functions fine- no smoke in the shop. The new one is on the right- still yet to be finished. Unfortunately there's no way around all the bends in the chimney and I understand this is my main problem. Fortunately I have about 25 feet of vertical height outside the building which offsets this mostly . I'm just pushing it a bit far with the new side blast forge I think. Most of the smoke goes up the chimney, but I'd like a little more 'suck' for those moments when it's a bit more smoky.

-

Anyone have experience/thoughts with sticking an inline booster fan into the system to help a poorly drawing coal forge chimney? Something like this:

Remove commercial link per TOS.

Oil on Bradley brake

in Power Hammers, Treadle Hammers, Olivers

Posted

How are Bradley owners keeping oil from the main shaft oil points dripping down onto the brake/fly wheel and preventing the brake from stopping efficiently?

I'm using a very thick die-set oil to lubricate those points.