Wayne

Members-

Posts

539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Wayne

-

It looks similar to what I know say a coal hammer, my grandad used one for smashingle up the largest bits for the fire. He was a mineral not a Smith. xxxx auto predict

-

Does anyone do hammer and chisel engraving?

Wayne replied to Glenn's topic in Blacksmithing, General Discussion

Looking at the vice I am wondering if it is one in the museum of ironwork at Ruon in France -

How would one make a pike spear?

Wayne replied to Bill in Oregon's topic in Spears, Arrows, Pole arms, Mace/hammer etc.

Over here we have different styles of eel spears / gigs. The styles depend on the bed of the water you are fishing in - narrow rod type barbs for muddy bottoms and broader heavier barbs for rocky bottoms. There is a book that has a chapter on the variations called nets and coracles if I remember -

It was, not hard just tedious then I had to follow with another 130 1 1/2 by 2 fron 8mm dia rod.

-

-

That is true, but reading some of the norse saga's the sense of humour shown does give me the idea that having the legs sticking out may have appealed to some of the folks present??

-

You are probably right on that thought Thomas, A set of metal workers tools from the saxon period were found at Tattershall Thorpe near Lincoln in the remains of several wooden boxes having locks on them. There seems to be a pattern of reusing chests and boxes for other purposes, one of the best I know of is the Saxo-Norman burial ground excavated at York Minster some years ago. I need to double check my notes but if I remember correctly six or seven chests had been reused as coffins with all the fittings and locks attached, the best bit I found about this site is that one of the reused chests had been too short for the body so they had knocked one end out to make room so I have visions of this chest/coffin being borne through the streets with a pair of feet sticking out of the end......

-

I do not know who to credit for this. Found this on Pinterest, sorry its a little late, working over Xmas.

-

A scientist with the user name Thunderf00t has posted a film on you tube shooting down solar roadways a year or two back

-

Cheapo Spear (knif, byproduct)

Wayne replied to NFLIFe's topic in Spears, Arrows, Pole arms, Mace/hammer etc.

Is it a spear? A short haft and small head you have a nice javelin for throwing -

We go down the forge to relax after watching cricket, especially after the pasting we got from india....

-

Hi Daswolf I am not really sure but metal calculators give 170lb for a block of steel 5" by 10" by12". I know I was struggling to lift it into the boot of my car.

-

Watching BBC look north news for Lincolnshire last night up came a segment on how we need people as the old crafts are dieing out so students have created a virtual blacksmiths shop using 3D goggles so that people can try out smithing to see if they like it ??? I was hoping it was a spoof but everyone they interviewed thought it was a wonderful idea.

-

After the last month or so working silly shifts I finally got some me time and treated myself to this... only 18 miles down the road and £60 18" overall 12 by 5 face and 10" high, the hardie hole is 3/4" square. There are no markings I can find but I guess it is fairly early.

-

OK, not sure where this needs to go - possibly the safety section?? But whatever, just seen this guy on YouTube, check out the wheel of debt wood splitter. This has to be a Darwin award waiting to happen.

-

Just catching up, Thoughts and best wishes from this side of the pond. Wayne

-

Hi To my knowledge there are two forms of turns crew, the first is an early name for screwdrivers. In the 1870 catalogue for William Marples and sons in Sheffield there are a range of different sized screwdrivers but they are described as turns crews ie - Long handled cabinet makers turns crew, Scottish pattern turns crew. A nice little book on the history of screws is - One good turn by Witold Rybczynski, ISBN 0-7432-0850-1 The other turns crew dates to the Victorian prison system, the Victorians were of the idea that the devil made works for idle hands. So they came up with various ideas to keep the prisoners busy - breaking rocks, dig a hole and fill it in then dig it out again as well as what was effectively a giant hamster wheel that the prisoners walked up on the outside like a endless stair case and then there was the Crank. Imagine a post rising from the floor on top of which was a box, in the box was a wheel and on the outside was a crank to turn the wheel. Also on the box was a screw, the prisoner would be sentenced to turn the crank so many thousand times. Now depending on his sentence or the guards the screw could be turned one way to release friction on the wheel or the other way to increase friction, think of how a modern exercise bike works..... The crank did not actually do anything it was to occupy the prisoner, if he did not complete the required amount of turns on the crank he would be further punished. This led to the guards acquiring the nick name Turns crews which was later shortened to Screws. Sometimes if you see an old black and white British film you may hear a crook say some thing like "look out here come the screws" There is a replica crank in the old Victorian prison in the grounds of Lincoln castle if you are ever that way. Hmm for some reason my tablet does not like turnscrew. As one word. The Birmingham firm of Timmins and sons tools pattern book of 1845 also uses the term turnscrews for screwdrivers.

-

My thoughts with yoou all. My daughter went through the same at 7 months

-

That's pretty, well done

- 17 replies

-

- Hand forged

- Ballnuts

-

(and 5 more)

Tagged with:

-

Hi Kozzy There is another medieval book from Germany circa 1470/1480 showing a thread cutting lathe with a tool post and replaceable cutting tip, I will dig out the picture.

-

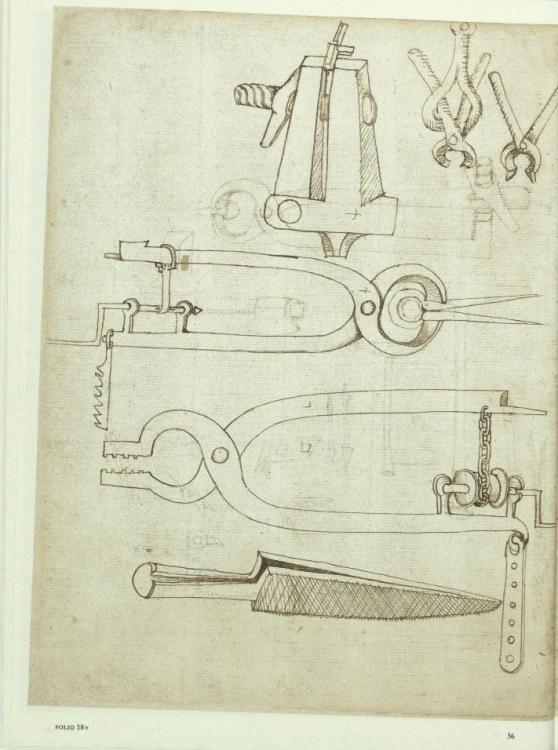

I have spent ages looking for a medieval vice, the earliest illustrations I have seen were in the Mendel Hausbuch from around 1515. Now I have come across a book by Marriano Taccola - 1382-1453 who wrote two books - De Ingeneis and De Machinis. Think a medieval Leonado, and there it is............

-

Mad max at holloween or for school project?

-

Just think of the custom fittings you can make for it...

-

Who is going to be the biggest kid and play with it the most?

-

The only time I have problems with smoke is when first lighting a coal fire, with charcoal you have to watch out for sparks/fleas being blown in to the audience. I agree with Frosty about form and function, go with the KISS principle and find out what works then you can add the flash later - a good coat of heat proof paint makes a lot of difference to rust and welds for a small outlay. Side blast or fire pot? to most of the people watching it does not matter, all they will see is a pile of coal/coke/charcoal and the fire. I find most folks are interested in seeing the bellows work than the hearth itself - it certainly gets the conversation going. If you have the hood as in JohnB's pictures then unless you turn the hearth round they are not going to see any of the fittings at the rear so why the trouble, cost and weight? The main things you will find the public want to know are often - is it a real fire? what are you cooking? do you shoe horses? my --------------- was a blacksmith etc Some things I find at demo's is that it is hard work on your own, you will have folks round as soon as the fire is lit and you will have a devil of a time trying to catch a break. Also show the organisers you are serious - safety ropes, visible fire extinguishers, have documents to hand, insurance etc.. if you look and act professional it scores a lot of brownie points. Sorry for the long missive Wayne

- 58 replies

-

- side blast

- super sucker

-

(and 2 more)

Tagged with: